Hello everyone. I recently purchased an Attack DP 35kW gasification boiler and I am about ready to start my install. I have attached a pdf of the piping design and I would like to get some feedback on it. I have heated with wood all of my life but this is my first go with an outdoor system. My house is all new construction so it is decently efficient. The only thing that is set in stone so far is the location of both water heaters, both air handlers, and the fact that I already have the boiler. I do not have any piping, valves, or accessories yet so I am open to any ideas that will help me decide how to set this up. I am not going to install a storage tank this year but I plan to in the future. Any help or ideas that you have will be greatly appreciated.

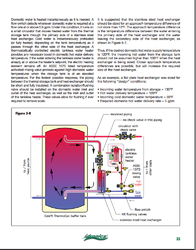

Gasification Boiler piping diagram

- Thread starter jbean88

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

mmudd

Member

Hello everyone. I recently purchased an Attack DP 35kW gasification boiler and I am about ready to start my install. I have attached a pdf of the piping design and I would like to get some feedback on it. I have heated with wood all of my life but this is my first go with an outdoor system. My house is all new construction so it is decently efficient. The only thing that is set in stone so far is the location of both water heaters, both air handlers, and the fact that I already have the boiler. I do not have any piping, valves, or accessories yet so I am open to any ideas that will help me decide how to set this up. I am not going to install a storage tank this year but I plan to in the future. Any help or ideas that you have will be greatly appreciated.

I'm not an expert and someone here probably will have a different/ better opinion, but I offer the following:

Looks like no storage planned, but I'd recommend leaving that option open as you plan the system.

Your garage water to air HX and the upstairs supply looks like it will run off the boiler pump. This would not be good if you ever add storage. Storage allows supply to heat load even if no fire in boiler. If no fire in boiler, pump should not be running. No pump going at boiler means no heat to your various heat zones with your plan so you'd need to change piping if you add storage later. Plus you would not want flow thru boiler if there is no fire, which causes heat loss.

I think making the run thru the boiler as a loop (or to/from storage someday), then tee off in supply return fashion with pumps to each zone would be better. You could use primary secondary arrangement off this boiler loop but beware of temp drop at loads further down the loop.

I would not run main level water/air HX and domestic hot water off the same pump. I guess you could use zone valves to control flow thru each. You wouldn't want flow thru water/air HX every time your domestic hot water system calls for heat and vice versa. Not sure if you plan to heat domestic HW in summer, but flow thru HX in summer could mess with AC system if you have one. An outside boiler makes summer use possible. Also no need for domestic hot water in water heater to be 180 degrees and when when you are supplying the water air HX or run hot water thru water/air HX when house not calling for heat. I'd probably have separate pumps where you tee off to go to each appliance or zone valves

If you never plan to have storage, you could maybe size boiler pump to handle all flow and use zone valves to control flow. With a gssification boiler, Storage is recommended and worthwhile.

I used pipe diagram from Tarm USA. They have lots of different designs to choose from. On my system, flow goes from boiler to storage always, then my heat loads tee off of boiler to storage loop. I used pumps rather than Zone valves. It works really good and is an easy set up to control using standard multi zone controller like TACO or others. This allows heat load supply when boiler is not fired. Tarm USA is very helpful and will look at your specific design and provide comments.

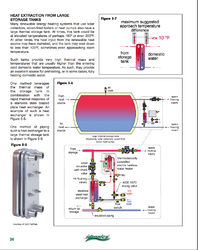

Thanks for the pointers mmudd. I have researched my system further and made another diagram. Let me know what you think. I went this week and looked at two systems that my neighbors have installed using central boiler owb. Their designs are a single loop that has the water to air HX and DHW in series and the pump runs constantly. However, this does not conform to any other designs that I have found. Is this because they have more water capacity in the boiler? My Attack has a controller that turns the main pump on and off which can be controlled by a thermostat in my house. This is confusing me about how this system is designed to work. The further I dig into this the more confused I become! Thanks for your help!

Attachments

mmudd

Member

Thanks for the pointers mmudd. I have researched my system further and made another diagram. Let me know what you think. I went this week and looked at two systems that my neighbors have installed using central boiler owb. Their designs are a single loop that has the water to air HX and DHW in series and the pump runs constantly. However, this does not conform to any other designs that I have found. Is this because they have more water capacity in the boiler? My Attack has a controller that turns the main pump on and off which can be controlled by a thermostat in my house. This is confusing me about how this system is designed to work. The further I dig into this the more confused I become! Thanks for your help!

Hmmn! You are quickly exceeding my hydonic knowledge. What happens when the boiler is hot and no zones are calling for heat?....Is the green line a bypass with a zone valve for that situation? Looks a pressure regulated pump would be suggested in that scenario, so that it the speed of the pump is relative to how many zones are calling for heat. Be sure to calculate the flow / head requirements of the boiler pump and various zones to assure your pumps will handle it. Also, I think you'd want to make sure the pump supplying various zones does not run unless your boiler is hot with a diagram like that.

Clarkbug

Minister of Fire

jbean, welcome to Hearth!

mmudd has you on the right track, and I wanted to add a few thoughts/opinions.

OWBs have a single loop because they have to keep water moving to prevent things from freezing, typically. They circulate the water through their water jacket and storage, and there is an aquastat in there that opens or closes the draft door (or cycles the fan) to maintain the water temps. Controls in the house then cycle the fan off or on when they want heat, and the DHW always stays warm when using a sidearm. Its simple and it works, but isnt the most efficient.

Your second diagram is much more what I would suggest than your first. The idea of having a piping manifold with a single variable speed pump and then zone valves should work out much better for you. You only need one zone valve per circuit, since if water cant get into the loop, it cant get out either, so dont bother with one on each line.

Be aware that with most plate exchangers on DHW you need two pumps, one for the boiler side, one for the DHW side. The DHW side has to be a bronze or stainless impeller, dont just use a boiler circ.

My understanding is that the attack can be a cycling boiler instead of batch burn, and maybe that pump is a cycling controller for temps? As in, it doesnt turn on until you are up to temp and then off again? (aka bang-bang control) But I honestly dont know, so please dont listen to me there for sure. I think member ewdudley has an attack? (I could also be wrong here too....)

Can your shed hold storage right now? Or would that go inside? (I hope you can put it in the shed...) DEFINITELY make provisions to tie in storage now if you can, to avoid re-work later.

mmudd has you on the right track, and I wanted to add a few thoughts/opinions.

OWBs have a single loop because they have to keep water moving to prevent things from freezing, typically. They circulate the water through their water jacket and storage, and there is an aquastat in there that opens or closes the draft door (or cycles the fan) to maintain the water temps. Controls in the house then cycle the fan off or on when they want heat, and the DHW always stays warm when using a sidearm. Its simple and it works, but isnt the most efficient.

Your second diagram is much more what I would suggest than your first. The idea of having a piping manifold with a single variable speed pump and then zone valves should work out much better for you. You only need one zone valve per circuit, since if water cant get into the loop, it cant get out either, so dont bother with one on each line.

Be aware that with most plate exchangers on DHW you need two pumps, one for the boiler side, one for the DHW side. The DHW side has to be a bronze or stainless impeller, dont just use a boiler circ.

My understanding is that the attack can be a cycling boiler instead of batch burn, and maybe that pump is a cycling controller for temps? As in, it doesnt turn on until you are up to temp and then off again? (aka bang-bang control) But I honestly dont know, so please dont listen to me there for sure. I think member ewdudley has an attack? (I could also be wrong here too....)

Can your shed hold storage right now? Or would that go inside? (I hope you can put it in the shed...) DEFINITELY make provisions to tie in storage now if you can, to avoid re-work later.

Thanks for the reply's Mmudd and Clarkbug. That definitely clears a few things up and makes me feel a little more confident that this is all going to work. The unlabeled green line is just a check valve to make a directional loop. The boiler also has ports for an overheat circuit which I did not draw but will use in the actual setup. I moved the main pump to the supply side because the software was implying that the return side was wrong. What side do I need to put it on? I also had check valves in the return lines but I took them out in this revision. Do I need them?

Correct me if I am wrong but from what I have read on this site and others is that the plate exchanger's can be used as a sort of on demand system. I understand that it will not circulate on the DHW side to keep the tank warm but some people are saying that it will heat the water fast enough to basically give you an endless supply. Plus I really do not want to add any more pumps than I absolutely have to. Although using it that way makes me question what would trigger the zone valve?

I have not ordered the concrete yet for my shed so I am open to suggestions but I was planning on a 10'x16'. This boiler is small compared to the OWB's so I was thinking it would leave me room for a 500 gal tank and a good amount of wood. But the tank will come later.

Thanks again!

Correct me if I am wrong but from what I have read on this site and others is that the plate exchanger's can be used as a sort of on demand system. I understand that it will not circulate on the DHW side to keep the tank warm but some people are saying that it will heat the water fast enough to basically give you an endless supply. Plus I really do not want to add any more pumps than I absolutely have to. Although using it that way makes me question what would trigger the zone valve?

I have not ordered the concrete yet for my shed so I am open to suggestions but I was planning on a 10'x16'. This boiler is small compared to the OWB's so I was thinking it would leave me room for a 500 gal tank and a good amount of wood. But the tank will come later.

Thanks again!

Attachments

Clarkbug

Minister of Fire

Typically you want the pump away from the boiler so you dont add additional pressure to it.

Plate exchangers can be used like they are on-demand, but only if you size it for heating your 50 degree incoming water up to where you want it, and thats a BIG load usually. The plate Hx can only heat water as fast as you want it if you have water pumping through both sides. Unless your intent is to just hook domestic water straight to the DHW side of the Hx.... I would advise against this to be honest. You probably wont be happy with the performance, or at least it will be very expensive to get it to work the way you want.

Zone valves can be controlled any number of ways. Aquastats are one way (for your DHW), and thermostats connected to a zone controller are another. Taco, Caleffi, Honeywell and others make zone controllers that should work for you. Or some valves will work directly with a T-stat, and you wouldnt need the zone controller.

Figure out the size tank you want, then add some space around it for piping and then insulating, and then make sure you have some good clearances if you ever have to work on it again once its installed. 10x16 is a good sized shed, but you might want more depending on how you lay it out and how you want to get your wood in there.

Plate exchangers can be used like they are on-demand, but only if you size it for heating your 50 degree incoming water up to where you want it, and thats a BIG load usually. The plate Hx can only heat water as fast as you want it if you have water pumping through both sides. Unless your intent is to just hook domestic water straight to the DHW side of the Hx.... I would advise against this to be honest. You probably wont be happy with the performance, or at least it will be very expensive to get it to work the way you want.

Zone valves can be controlled any number of ways. Aquastats are one way (for your DHW), and thermostats connected to a zone controller are another. Taco, Caleffi, Honeywell and others make zone controllers that should work for you. Or some valves will work directly with a T-stat, and you wouldnt need the zone controller.

Figure out the size tank you want, then add some space around it for piping and then insulating, and then make sure you have some good clearances if you ever have to work on it again once its installed. 10x16 is a good sized shed, but you might want more depending on how you lay it out and how you want to get your wood in there.

Bob Rohr

Minister of Fire

Typically you want the pump away from the boiler so you dont add additional pressure to it.

Plate exchangers can be used like they are on-demand, but only if you size it for heating your 50 degree incoming water up to where you want it, and thats a BIG load usually. The plate Hx can only heat water as fast as you want it if you have water pumping through both sides. Unless your intent is to just hook domestic water straight to the DHW side of the Hx.... I would advise against this to be honest. You probably wont be happy with the performance, or at least it will be very expensive to get it to work the way you want.

Zone valves can be controlled any number of ways. Aquastats are one way (for your DHW), and thermostats connected to a zone controller are another. Taco, Caleffi, Honeywell and others make zone controllers that should work for you. Or some valves will work directly with a T-stat, and you wouldnt need the zone controller.

Figure out the size tank you want, then add some space around it for piping and then insulating, and then make sure you have some good clearances if you ever have to work on it again once its installed. 10x16 is a good sized shed, but you might want more depending on how you lay it out and how you want to get your wood in there.

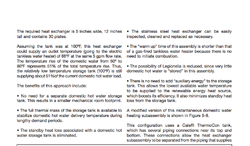

I'm a big proponent of DHW via a plate HX. It is a very do-able technology and you can produce shower temperature with tank temperatures as low as 120F. A small gas or electric tankless could be used for additional boost if the tank temperature drops too low.

I have one system with a 5X12- 20 plate and another with a 3X8-40 plate. The 3X8 is on an 80 gallon solar tank, with an LP burner backup should the tank drop to 120F, the burner takes over.

The 80 gallon is fed from a 160 solar tank, so I store plenty of power to run DHW for several days without sun.

My LP fired Lochinvar Knight has a 3X8 20 plate with a 120,000 BTU boiler firing to 190F. All three will product right around 3 gpm.

Unless you have an unusually large DHW load in excess of 3 gpm, these work well.

Here are some examples, a link to a DHW tech journal for more DHW ideas.

If you have hard water they will need to be flushed from time to time, just like a tankless DHW heater. Add a couple flush valves on the potable side, or unions to remove the entire HX to flush.

I have one customer that takes his plate HX to a radiator shop every 3 years for an acid cook.

http://www.caleffi.com/sites/default/files/coll_attach_file/idronics_11.pdf

Attachments

Clarkbug

Minister of Fire

maple1

Minister of Fire

I use a Johnson A-419 controller to control my DHW stuff.

I mounted the temp probe for it right at the bottom inlet of my DHW tank, as close in as I could get it. This is where fresh water (pre-heated) comes in, but is also where the recirc heating loop that goes thru my exchangers draws from. It opens & closes a zone valve on the boiler side of my DHW exchangers. The end switch in the zone valve is wired to start the boiler side zone circ pump (an Alpha), same as the end switches on my heating zones. I also ran another pair of wires from that end switch to a separate RIB relay, that has the DHW-side circ pump (a B&G Ecocirc) on the other side. So when the Johnson sees a cold temp, it opens the zone valve on the boiler side, which then starts the two circ pumps on each side. Works pretty darn good.

One other thing about the Johnson that I didn't realize until I had it all up & running, is there is another circuit in it that when closed (or opened, forget which now) it shifts the setpoint by a programmed amount. For now, I have that going through an ordinary on/off switch, that I hit when I burn, and un-hit when done burning. I have some thermal switches around here - I will be putting one of those on the pipe on my boiler return line right outside the boiler so that when it sees hot water (i.e. when it sees that I'm burning), it will automatically shift my DHW setpoint 20° (or whatever) higher. My DHW tank is 80 gallons - so it in effect is increasing my storage capacity and making the most of my burning times.

I really like that Johnson - it's a pretty sweet controller. Has a digital temp display too. Aquastat wells are so 1960's.

I mounted the temp probe for it right at the bottom inlet of my DHW tank, as close in as I could get it. This is where fresh water (pre-heated) comes in, but is also where the recirc heating loop that goes thru my exchangers draws from. It opens & closes a zone valve on the boiler side of my DHW exchangers. The end switch in the zone valve is wired to start the boiler side zone circ pump (an Alpha), same as the end switches on my heating zones. I also ran another pair of wires from that end switch to a separate RIB relay, that has the DHW-side circ pump (a B&G Ecocirc) on the other side. So when the Johnson sees a cold temp, it opens the zone valve on the boiler side, which then starts the two circ pumps on each side. Works pretty darn good.

One other thing about the Johnson that I didn't realize until I had it all up & running, is there is another circuit in it that when closed (or opened, forget which now) it shifts the setpoint by a programmed amount. For now, I have that going through an ordinary on/off switch, that I hit when I burn, and un-hit when done burning. I have some thermal switches around here - I will be putting one of those on the pipe on my boiler return line right outside the boiler so that when it sees hot water (i.e. when it sees that I'm burning), it will automatically shift my DHW setpoint 20° (or whatever) higher. My DHW tank is 80 gallons - so it in effect is increasing my storage capacity and making the most of my burning times.

I really like that Johnson - it's a pretty sweet controller. Has a digital temp display too. Aquastat wells are so 1960's.

mmudd

Member

My understanding is that the plate HX would probably work on demand, if the domestic H2O supply water lines bypass the domestic hot water heater . If your hot water supply is thru the domestic hot water heater, it would take a while to heat up 40 gallons of water by convection unless you were using aquastat to cycle the flow thru the plate HX to maintain min temp in water heater tank, allowing convection time to heat the tank. Don't think you could have continuous hot water relying on convection, but a circulator on water heater side might make it happen? I think to switch between boiler supplied hot water to electric or gas domestic water heater, you'd have to open/ close valves, which I would avoid having to do if possible.

Bob Rohr

Minister of Fire

My understanding is that the plate HX would probably work on demand, if the domestic H2O supply water lines bypass the domestic hot water heater . If your hot water supply is thru the domestic hot water heater, it would take a while to heat up 40 gallons of water by convection unless you were using aquastat to cycle the flow thru the plate HX to maintain min temp in water heater tank, allowing convection time to heat the tank. Don't think you could have continuous hot water relying on convection, but a circulator on water heater side might make it happen? I think to switch between boiler supplied hot water to electric or gas domestic water heater, you'd have to open/ close valves, which I would avoid having to do if possible.

Bob Rohr

Minister of Fire

`A few options, you could install the plate downstream of the dHW tank, turn the tank down or off when you have solar or wood running, or the buffer tank is hot.

Or use one of the long tube HX that the OWF industry sells, but it is a slow transfer without a pump to circulate.

With the plate HX downstream of the DHW, the tank could be set low when you have a house full of guest to pre-heat to the plate HX to give you more GPM.

The goal with the instant, plate HX is you don't store DHW. If you have a wood boiler, or solar tank, the thermal energy is stored there, no need to store it in a second tank. It saves space, and limits heat loss from an additional tank.

It is better suited for light to moderate loads, not great for large families or multiple high gpm load households.

Always use a listed thermostatic valve on the outlet of the tank or plate HX if it is allowed to run to boiler temperature.

Those long tube HX from the OWF guys are prone to scalding conditions, even tripping high limit controls on the water heater tanks, be careful!

Or use one of the long tube HX that the OWF industry sells, but it is a slow transfer without a pump to circulate.

With the plate HX downstream of the DHW, the tank could be set low when you have a house full of guest to pre-heat to the plate HX to give you more GPM.

The goal with the instant, plate HX is you don't store DHW. If you have a wood boiler, or solar tank, the thermal energy is stored there, no need to store it in a second tank. It saves space, and limits heat loss from an additional tank.

It is better suited for light to moderate loads, not great for large families or multiple high gpm load households.

Always use a listed thermostatic valve on the outlet of the tank or plate HX if it is allowed to run to boiler temperature.

Those long tube HX from the OWF guys are prone to scalding conditions, even tripping high limit controls on the water heater tanks, be careful!

- Status

- Not open for further replies.

Similar threads

- Replies

- 6

- Views

- 1K

- Replies

- 5

- Views

- 1K

- Replies

- 8

- Views

- 603

- Replies

- 9

- Views

- 2K