I always run my gasifier flat-out. I let it heat the house and storage, then let it go out. That means I build fires a lot - every day in cold weather. I've been looking at how to get from lighting the match up to 'safe' inlet temperature, then up to 'usable heat' as quickly as possible. I've made some progress, but I'm looking for any tricks, techniques, or ideas from the vast collective wisdom of the forum. How can I improve on this?

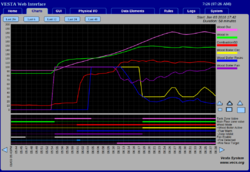

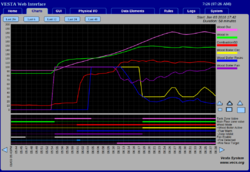

Here's what a fresh fire looks like on my system now:

Here's what a fresh fire looks like on my system now:

- At about 5:47, I turn off the 'Fan Enable' switch in preparation for fire building.

- At about 5:54, I light the fire and enable the fan. At this point the bypass damper is open. Several things happen:

- The wood boiler fan comes on at full speed to get the fire going.

- The Vesta starts a preheat cycle:

- All the heat loads (Main Floor etc.) are inhibited

- The storage tank zone valve opens

- The wood boiler circ comes on at full speed to heat the wood boiler from storage

- The fire is starting and the boiler inlet temperature is rising due to circulation from storage.

- At 6:01, I close the damper. That causes combustion temperature to spike.

- The Vesta recognizes that a fire has started

- The Vesta switches to 'Wood Mode'

- At 6:04, the Vesta preheat cycle ends and the wood boiler recirculator is enabled (inlet protection), aiming at 140 degree inlet temp.

- At 6:11 'Fire Near Target' is achieved - the combustion temperature passes 1000 degrees. The wood boiler fan switches to PID control, aiming at 1100 degree combustion.

- At 6:14, inlet temperature reaches 140. Elapsed time since start: 20 minutes.

- At 6:19, boiler outlet reaches 155, my minimum usable heat value. 'Wood Boiler Active' becomes true. Elapsed time since start: 25 minutes.

- Zone Inhibit is canceled

- Heat load zone valves are allowed to open

- Wood boiler circulator switches to PID control, aiming at a boiler outlet temperature of 180.

- At 6:25, outlet temp reaches 180. Elapsed time since start: 31 minutes.

), to get useable water out of the boiler (160). I will try to time it later on today when I light - I might be off a bit. I am somewhat hampered on startup by not having a draft fan, so my draft needs to build on its own. 'Spooling up the turbo', I say. I have a couple of little things I do to try to make that happen as fast as possible, particular to my boiler.

), to get useable water out of the boiler (160). I will try to time it later on today when I light - I might be off a bit. I am somewhat hampered on startup by not having a draft fan, so my draft needs to build on its own. 'Spooling up the turbo', I say. I have a couple of little things I do to try to make that happen as fast as possible, particular to my boiler. , low of 0

, low of 0