Thank you all for all the insights.

Finally got Mama Bear and Baby Bear online, just before Christmas actually, but now have got some photos.

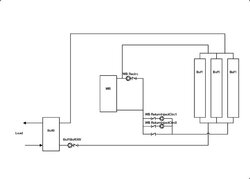

Boilers are adjacent to three vertical 250 gallon tanks, with taps into opposite ends at the apexes.

Power fail dump is by gravity into storage tanks through low resistance check valve.

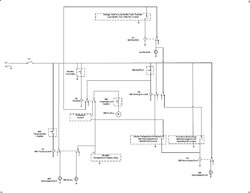

Return temperature control is accomplished by injecting into a boiler recirc loop with an injection pump under PID bang-bang control. With an 80 second cycle, 105 degF system return water, and a 160 degF return temperature setpoint I'm seeing a 10 deg F swing in return temperature with boiler discharge temperature steady at 170 degF. Push a button and you can set the return temperature anywhere you want it. Pumps were salvage, controller $40, relay with pedestal $12.

To prevent idling, the recirc pump is switched off and an additional injection pump is switched on with a salvaged Honeywell aquastat.

On high limit the flue fan is switched off with the Honeywell aquastat.

Burn cycle shuts down according to boiler flue neck temperature with another PID controller, using alarm relay function.

When burn cycle is complete a differential controller purges the boiler by pumping cool water into the boiler whenever the boiler discharge is hotter than system return temperature and the system load pump is running.

Yet another PID controller is used to control return temperature from a load buffer tank/hydraulic separator that provides heated water to the house. This works real well. Now in the dead of winter I need a minimum system return temperature of 108 degF to keep the least effective zone warm. During the mild spell at the end of December I was able to lower it to 95 degF. A Tekmar with outdoor reset would be a lot slicker.

Baby Bear and a ten year supply of coal is from leftover funds, but burning wood is more fun with no health club dues, and who knows, I might live longer than that.

Thanks again to all of you who have contributed so much to this forum.

Cheers --ewd

Finally got Mama Bear and Baby Bear online, just before Christmas actually, but now have got some photos.

Boilers are adjacent to three vertical 250 gallon tanks, with taps into opposite ends at the apexes.

Power fail dump is by gravity into storage tanks through low resistance check valve.

Return temperature control is accomplished by injecting into a boiler recirc loop with an injection pump under PID bang-bang control. With an 80 second cycle, 105 degF system return water, and a 160 degF return temperature setpoint I'm seeing a 10 deg F swing in return temperature with boiler discharge temperature steady at 170 degF. Push a button and you can set the return temperature anywhere you want it. Pumps were salvage, controller $40, relay with pedestal $12.

To prevent idling, the recirc pump is switched off and an additional injection pump is switched on with a salvaged Honeywell aquastat.

On high limit the flue fan is switched off with the Honeywell aquastat.

Burn cycle shuts down according to boiler flue neck temperature with another PID controller, using alarm relay function.

When burn cycle is complete a differential controller purges the boiler by pumping cool water into the boiler whenever the boiler discharge is hotter than system return temperature and the system load pump is running.

Yet another PID controller is used to control return temperature from a load buffer tank/hydraulic separator that provides heated water to the house. This works real well. Now in the dead of winter I need a minimum system return temperature of 108 degF to keep the least effective zone warm. During the mild spell at the end of December I was able to lower it to 95 degF. A Tekmar with outdoor reset would be a lot slicker.

Baby Bear and a ten year supply of coal is from leftover funds, but burning wood is more fun with no health club dues, and who knows, I might live longer than that.

Thanks again to all of you who have contributed so much to this forum.

Cheers --ewd