I have been planning, re-planning and re-re-planning a woodshed for quite awhile  . Each potential location on my sloped property had a fatal flaw or would require more of an investment than I wanted to make in my first build. I wanted a prototype, something I could learn from and then build a better one when needed. Hence the use of 2x4s.

. Each potential location on my sloped property had a fatal flaw or would require more of an investment than I wanted to make in my first build. I wanted a prototype, something I could learn from and then build a better one when needed. Hence the use of 2x4s.

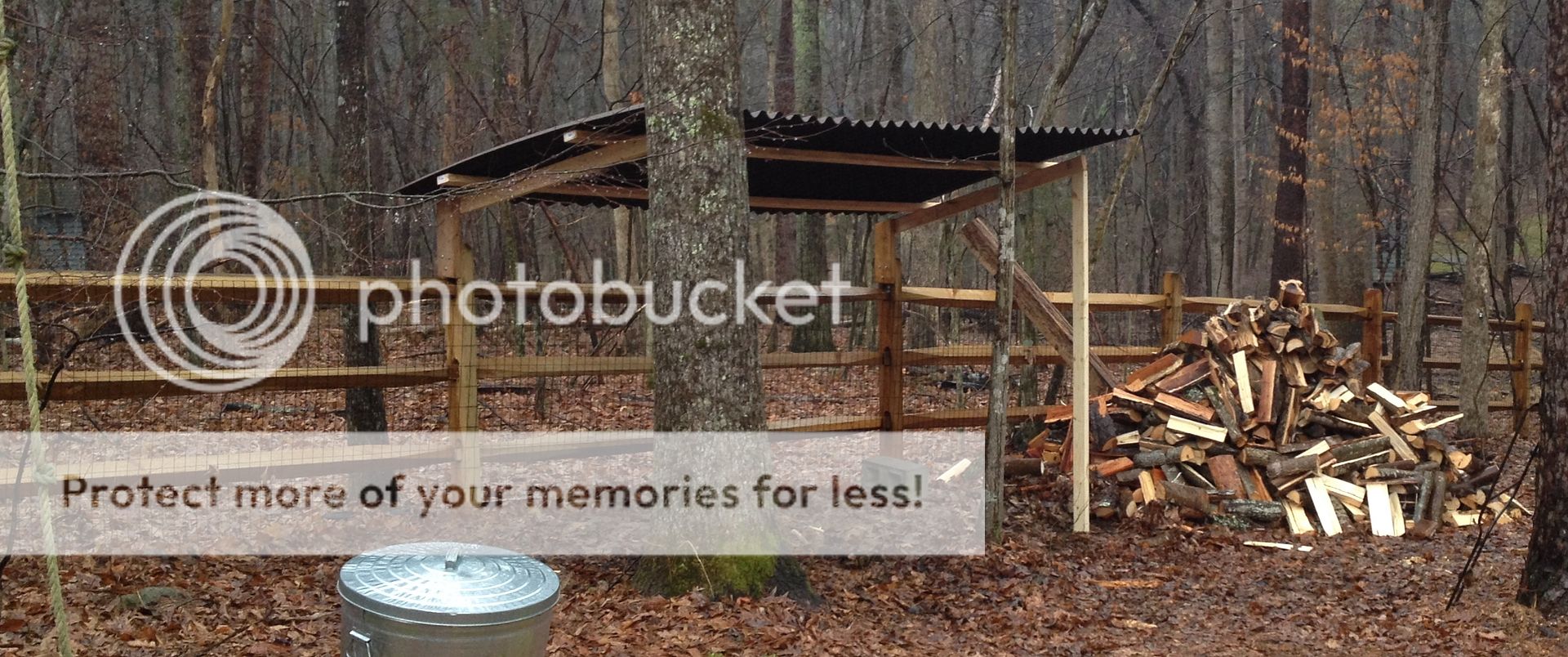

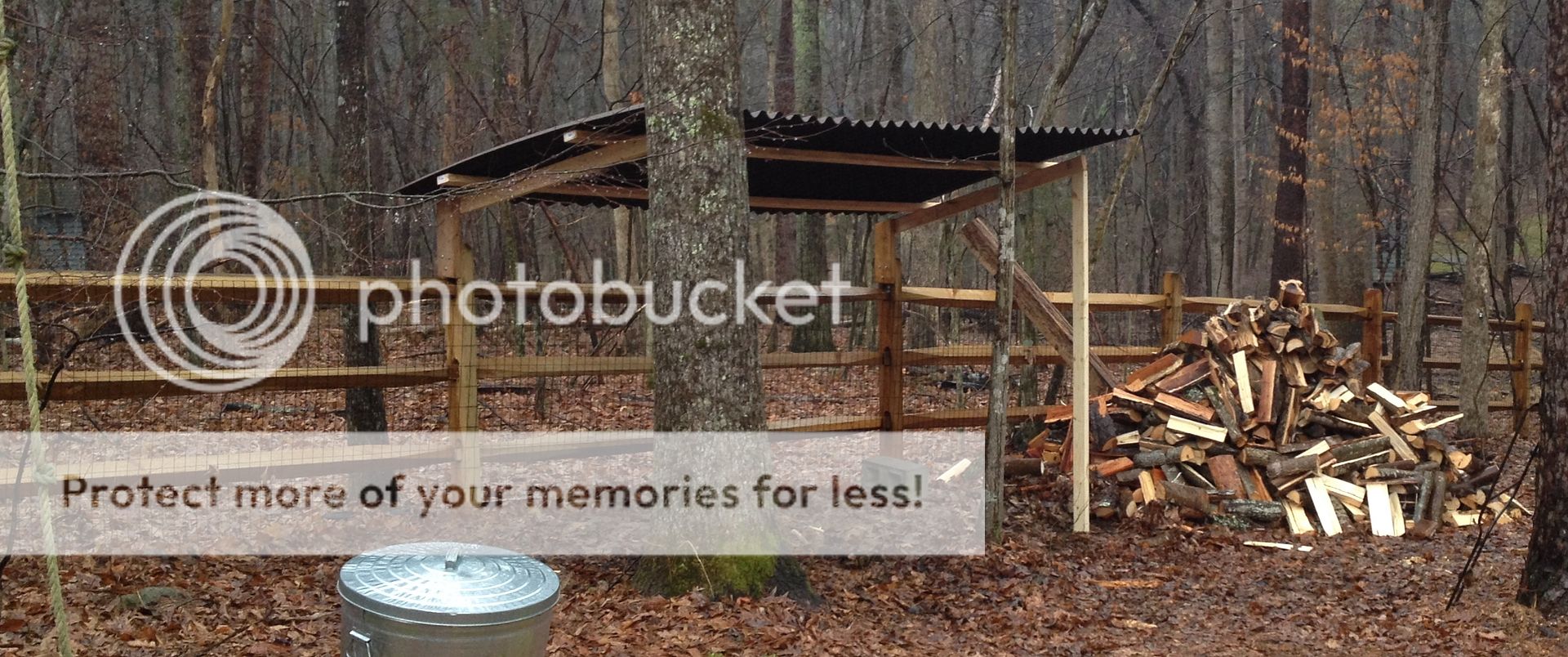

So here it is. The roofing panels are 6.5' x 4' corrugated cellulose from Lowes, so with 3 of them I currently have approximately 6' x 12' protected. I'll use pallets to stack on and try to level them out with misc. landscaping timbers and concrete blocks laying around. I built it like this as I can continue it along the fence line adding 10' x 6' at a time. The current 6' x 12' will only hold about a seasons worth of wood for me so I may add the additional length soon given recent scrounging success.

I went low-budget and used a 2x4 instead of a treated 4x4 post, but I did use a treated square of wood to rest the 2x4 on. Next build will involve a more proper post and footing as I'm starting to feel regrets already over this weakness. I also now know 10' is too wide a width for a 2x4 to support 3 of those panels. I can see some bow in it and the 6" we're expecting tonight will test it. Alternatively I could rebuild and turn the 2x4 up on edge for increased stability. I want to avoid inside posts because it's hard to get one centered with the pallet geometry.

. Each potential location on my sloped property had a fatal flaw or would require more of an investment than I wanted to make in my first build. I wanted a prototype, something I could learn from and then build a better one when needed. Hence the use of 2x4s.

. Each potential location on my sloped property had a fatal flaw or would require more of an investment than I wanted to make in my first build. I wanted a prototype, something I could learn from and then build a better one when needed. Hence the use of 2x4s. So here it is. The roofing panels are 6.5' x 4' corrugated cellulose from Lowes, so with 3 of them I currently have approximately 6' x 12' protected. I'll use pallets to stack on and try to level them out with misc. landscaping timbers and concrete blocks laying around. I built it like this as I can continue it along the fence line adding 10' x 6' at a time. The current 6' x 12' will only hold about a seasons worth of wood for me so I may add the additional length soon given recent scrounging success.

I went low-budget and used a 2x4 instead of a treated 4x4 post, but I did use a treated square of wood to rest the 2x4 on. Next build will involve a more proper post and footing as I'm starting to feel regrets already over this weakness. I also now know 10' is too wide a width for a 2x4 to support 3 of those panels. I can see some bow in it and the 6" we're expecting tonight will test it. Alternatively I could rebuild and turn the 2x4 up on edge for increased stability. I want to avoid inside posts because it's hard to get one centered with the pallet geometry.

As soon as I finished it I stepped back and had several things I wish I had done differently.

As soon as I finished it I stepped back and had several things I wish I had done differently.

)

)