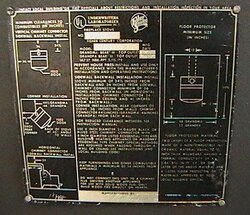

Hi, I have a top venting Grandpa Bear with the date on the arched doors as 4/20/88. I've read read almost all of the retrofit baffle posts.

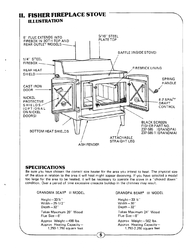

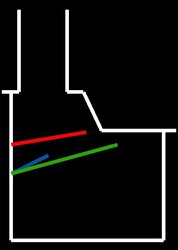

What bothers me is that my stove already seems to have a baffle, albeit a modest 6" deep. See pics. I am not the original owner. Is this a factory baffle? It feels fairly stationary so it is probably welded in. Will know more once I clean it up.

Anyway I'm going to assume I should put in a much deeper baffle. The measurements and positioning of it are clear. My question is: should I opt for a solid-steel-plate type baffle or a angle-iron-w/fitting-fire-bricks type baffle?

I would think the steel plate would be better because you want the baffle to get hot quickly so it can start doing its secondary burn job. Which would you guess is is better?

That will be my first project. What would be a good 2nd project to make this stove more efficient or easier to use?

Another question, what is the cursive weld bead writing on the bottom of my stove? All I can make out is "Carlton B.....". Is that the name of the welder?

Last edited by a moderator: