I

ISeeDeadBTUs

Guest

Sparke - observation since installing your top refractory?

General questions . . .

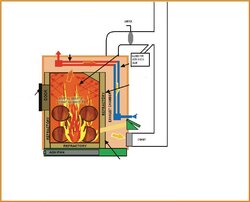

Whats everyone think about making the entire smoke path enclosed in refractory? This will be hard to describe . . .at the back of the original refractory, make a box which contains the HX and smoke path, then comes across the top of the horizontal HX tubes. One problem would be cleaning the HX. What about putting steel scrapers on a pivot, so that an external handle could be moved to actuate the scraping action. Of course, another problem of a completely enclosed refractory would be cleaning out in the back.

To cover the new style refractory, use Jess' panelized insulation separated by an air gap from the refractory.

Oh, and to back up the bus a bit . . . while reforming my skins it occurred to me . . . is there a PATTERN to where they rust through? I ask because, the side insulation actually contacts the side of the refractory. But behind the refractory (smoke path area) the insulation is directly exposed to the products of combustion. Is there a pattern to where we could say which area rusts worst?

Jimbo

General questions . . .

Whats everyone think about making the entire smoke path enclosed in refractory? This will be hard to describe . . .at the back of the original refractory, make a box which contains the HX and smoke path, then comes across the top of the horizontal HX tubes. One problem would be cleaning the HX. What about putting steel scrapers on a pivot, so that an external handle could be moved to actuate the scraping action. Of course, another problem of a completely enclosed refractory would be cleaning out in the back.

To cover the new style refractory, use Jess' panelized insulation separated by an air gap from the refractory.

Oh, and to back up the bus a bit . . . while reforming my skins it occurred to me . . . is there a PATTERN to where they rust through? I ask because, the side insulation actually contacts the side of the refractory. But behind the refractory (smoke path area) the insulation is directly exposed to the products of combustion. Is there a pattern to where we could say which area rusts worst?

Jimbo