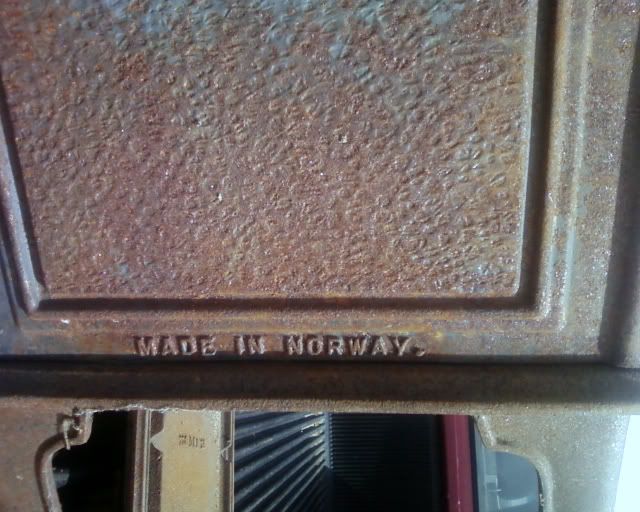

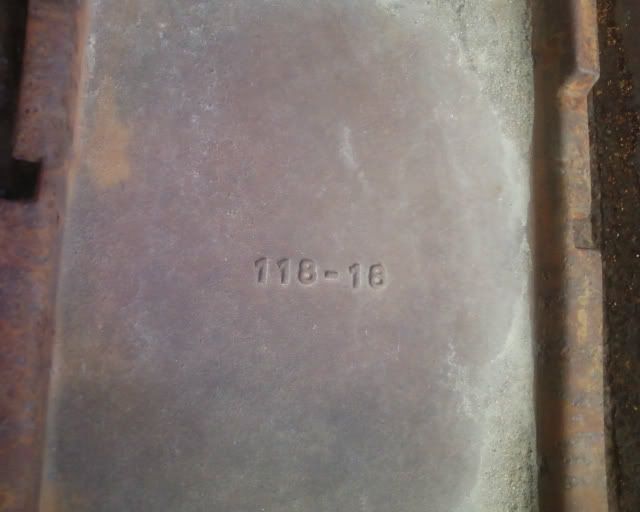

I couldn't contain my glee when I gave the guy $95 for an original Jotul-118. Yep, I gave it a once over and satisfied it was an original, I forked over the dough. When I lugged that beast into the house and started cleaning it my heart sank a little. On opposing corners of the top there are hairline cracks. One a little bigger than the other. Tipped it on it's side and noticed that a crack on the side relief split the pine tree right up the middle. It looks like it was brazed or maybe welded together. Probably welded because I can see a bead pattern. Also noticed that one of the side plates is diamond plate steel and not original of course. There are also several seams filled with furnace cement.

It's definitely seen better days. I'm only concerned about functionality at this point. Which brings me to a question? Where do I get an adapter that will fit? I'm running 6" black stovepipe to a stainless 6" supervent chimney wall mount kit. I measured the diameter of the stove flue and it's almost 4 1/2" in diameter. I picked up two 24" sections of black stovepipe and two elbows. If they make a 90 degree adapter I can take one of the elbows back. If not it's ok. Thanks. Also, why are there two removable plates on the sides of the box on top towards the rear? Just curious.

Pics:

It's definitely seen better days. I'm only concerned about functionality at this point. Which brings me to a question? Where do I get an adapter that will fit? I'm running 6" black stovepipe to a stainless 6" supervent chimney wall mount kit. I measured the diameter of the stove flue and it's almost 4 1/2" in diameter. I picked up two 24" sections of black stovepipe and two elbows. If they make a 90 degree adapter I can take one of the elbows back. If not it's ok. Thanks. Also, why are there two removable plates on the sides of the box on top towards the rear? Just curious.

Pics:

!!

!!