I just want to review what I have found online about head pressure. Since my EKO 40 will put out about 100,000 btu I think I will need to move about 10gpm. Assuming 10 gpm i belive 1" pex is about 6.1ft of head per 100' of pipe. Since I have 300' round trip I would have about 18.3ft of head in my pex alone. Add say 1 for the boiler and maybe 2 for the extra fittings and storage tank for a total of 22.3ft head. Acording to my taco 011 pump curve chart. 22ft of head is 10gmp. Are my assumptions correct in that I could get by with the 1" thermopex? I don't want my boiler going to idle because my lines won't move enough heat. 1 1/4 thermopex is not available in my area. Foam in trench is still being considered but I am concerned about the foam underground say 15-20 years from now.

Head pressure for 300ft of 1 inch pex

- Thread starter hartkem

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Karl_northwind

Minister of Fire

my quick calcs came up with a lot more head loss. that's probably because you're working above the maximum flow rate for 1" pex. my chart lists it as 7.5 gpm. not that that's an absolute, it's just working in the range of acceptable fluid flow rates of 4 ft/sec. My calculator gave me 41' head, too high for most circs, and can cause lots of other problems in your circuit.

Look up "Taco TD-10, sizing circulators". it's a great resource.

if your delta T can be larger, you can lower the flow rate, and get into the realm of normalness and work ok.

Is this piping between your boiler and storage, or from storage to load?

another good resource is to look up Caleffi Idronics 10. bio-mass piping scenarios and tips.

karl

Look up "Taco TD-10, sizing circulators". it's a great resource.

if your delta T can be larger, you can lower the flow rate, and get into the realm of normalness and work ok.

Is this piping between your boiler and storage, or from storage to load?

another good resource is to look up Caleffi Idronics 10. bio-mass piping scenarios and tips.

karl

This pipe is between boiler and storagemy quick calcs came up with a lot more head loss. that's probably because you're working above the maximum flow rate for 1" pex. my chart lists it as 7.5 gpm. not that that's an absolute, it's just working in the range of acceptable fluid flow rates of 4 ft/sec. My calculator gave me 41' head, too high for most circs, and can cause lots of other problems in your circuit.

Look up "Taco TD-10, sizing circulators". it's a great resource.

if your delta T can be larger, you can lower the flow rate, and get into the realm of normalness and work ok.

Is this piping between your boiler and storage, or from storage to load?

another good resource is to look up Caleffi Idronics 10. bio-mass piping scenarios and tips.

karl

Bob Rohr

Minister of Fire

I just want to review what I have found online about head pressure. Since my EKO 40 will put out about 100,000 btu I think I will need to move about 10gpm. Assuming 10 gpm i belive 1" pex is about 6.1ft of head per 100' of pipe. Since I have 300' round trip I would have about 18.3ft of head in my pex alone. Add say 1 for the boiler and maybe 2 for the extra fittings and storage tank for a total of 22.3ft head. Acording to my taco 011 pump curve chart. 22ft of head is 10gmp. Are my assumptions correct in that I could get by with the 1" thermopex? I don't want my boiler going to idle because my lines won't move enough heat. 1 1/4 thermopex is not available in my area. Foam in trench is still being considered but I am concerned about the foam underground say 15-20 years from now.

Plain water I assume?

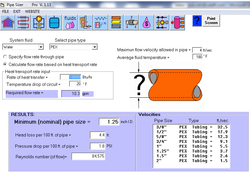

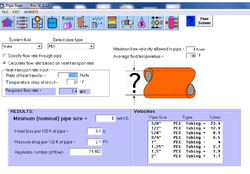

Not ideal. Here are some runs from an industry pipe sizer program. Best I can get is 72,000 BTU/ hr thru 1" pex. 1-1/4" is much better suited for that flow rate.

Will it work? probably but you will have some high velocity and require @ 200 W high head circ to accomplish the task. Sometimes you can push that velocity number a bit if it is an intermittent flow, but a heating system may be running 24/7 under design conditions. With 1/1/4 you could move the load with a 70W pump.

i understand your challange, this is one area that many wish they had done differently

Attachments

ewdudley

Minister of Fire

Your head loss numbers look right.I just want to review what I have found online about head pressure. Since my EKO 40 will put out about 100,000 btu I think I will need to move about 10gpm. Assuming 10 gpm i belive 1" pex is about 6.1ft of head per 100' of pipe. Since I have 300' round trip I would have about 18.3ft of head in my pex alone. Add say 1 for the boiler and maybe 2 for the extra fittings and storage tank for a total of 22.3ft head. Acording to my taco 011 pump curve chart. 22ft of head is 10gmp. Are my assumptions correct in that I could get by with the 1" thermopex?

You're assuming 20 degF deltaT, which I would hope is quite pessimistic. Have a look at the Tarm reference designs and see how they use a diverting valve to minimize return temperature to storage. Using a diverting valve or some other return temperature minimizing scheme you could should be able to get your return temperature from storage to the boiler down below 140-150 degF, even if the bulk of your load is a water air HX.

With 30 or 40 degF deltaT to work with your required flow goes down to less than 7 gpm and a head loss of 10 or 12 ft H2O, a flow rate a 70 watt 008 could provide easily through 300 feet of 'one inch' (0.863 inch) pipe.

However to get your flow rate high enough through your boiler you may need a separate boiler recirc loop with its own small pump.

And it's not a matter of making do, or getting by. If the requirement is to move 100000 btu per hour with a deltaT of 30 degF, the 6.67 gpm will do the job with certainty, and without compromise. A bigger pump or bigger pipe would be a waste.

taxidermist

Minister of Fire

Take it from me.........get 1 1\4 I was sold 1" for a 300' run and i am using a taco 013 and the pump cavates bad trying to force the water thru the 1"

ewdudley

Minister of Fire

Sounds more like a design failure than a pipe diameter problem.Take it from me.........get 1 1\4 I was sold 1" for a 300' run and i am using a taco 013 and the pump cavates bad trying to force the water thru the 1"

taxidermist

Minister of Fire

Sounds more like a design failure than a pipe diameter problem.

Nope you can only move so much water thru a 1" pipe

ewdudley

Minister of Fire

Quite true. But doesn't change the fact that using the wrong pump -- and connecting it such that there can be cavitation -- is a design failure, not a problem with the pipe diameter per se. You could just as easily have cavitation with 1.25" pipe if you used the wrong pump and didn't know what you're doing. Just saying.Nope you can only move so much water thru a 1" pipe

taxidermist

Minister of Fire

Well mine is set up like all the other systems I see here and with running the numbers it comes down to this..... too much pump for 1" pex to try and transfer the amount of btu my boiler will put out. Just sayingQuite true. But doesn't change the fact that using the wrong pump -- and connecting it such that there can be cavitation -- is a design failure, not a problem with the pipe diameter per se. You could just as easily have cavitation with 1.25" pipe if you used the wrong pump and didn't know what you're doing. Just saying.

Rob

Karl_northwind

Minister of Fire

you might want to talk to some who are more experienced than I about running the boiler, but you might not be able to move enough GPM to get a smaller delta t at the end of storage tank charging, when the incoming temps from the storage start to rise above 170F.

karl

karl

Karl_northwind

Minister of Fire

you might investigate raising the pressure of your system or moving your expansion tank in relation to that circulator to reduce cavitating. It should go without saying that you should observe all necessary and prudent safety measures etc. if you look that route.Well mine is set up like all the other systems I see here and with running the numbers it comes down to this..... too much pump for 1" pex to try and transfer the amount of btu my boiler will put out. Just saying

Rob

karl

heaterman

Minister of Fire

You are on the right track with the 1-1/4"

Running a high head circ (which you will undoubtedly need with 1") is just total waste of energy in the long term.

Running a high head circ (which you will undoubtedly need with 1") is just total waste of energy in the long term.

ewdudley

Minister of Fire

The right size is the right size. Foolishly insisting arbitrarily that bigger is better will necessarily lead to wasting money on pipe that is too big, a pump that is too big, or both.You are on the right track with the 1-1/4"

Running a high head circ (which you will undoubtedly need with 1") is just total waste of energy in the long term.

In my case I knew I could reliably achieve a system deltaT of over 60 degF and that my peak heat load was less than 70000 btu per hour. Taking into account the pipe length and a few elbows it worked out that 150 feet of nominal 0.75" (0.66" actual) diameter PEX and a "high head" Taco 008 pump could easily move 3.5 gpm, which of course works out to 105000 btu per hour. The numbers said I could heat my house with 0.75" pipe and a 71 watt pump and by golly it all came true. For as many hours as the pump will be running over the life of the system, the arithmetic could not justify a bigger pipe and a lower wattage high-efficiency pump that would have a very hard time paying for itself in the years to come.

It's all a simple and most straightforward graphical solution to very straightforward engineering problem.

Any plumber can cover his butt by going with 1.25" pipe that is undoubtedly big enough, throw in a 0011 or a 0013 that is undoubtedly powerful enough, and spend enough of the customers' money to keep them warm.

But here is a case where a fellow can take what he learned in eighth grade, sharpen his own pencil, and save a fair amount of money in both capital and operating expense simply by working the numbers and believing the truth. If a1.25" pipe and a 0013 is required, so be it, but anyone signing the check for a new system owes it to themselves to run the numbers and get it right, as opposed to following anonymous, unsupported, and categorical advice and just throwing money at the problem, motivated by fear and uncertainty.

--ewd

woodsmaster

Minister of Fire

Very true Eliot. I put in 1 1/4" undergroung pipe due to fear and uncertainty. Knowing what I Know now I could have easily gotten away with 1" and saved a few hundred dollers.

jebatty

Minister of Fire

In my case I knew I could reliably achieve a system deltaT of over 60 degF and that my peak heat load was less than 70000 btu per hour. Taking into account the pipe length and a few elbows it worked out that 150 feet of nominal 0.75" (0.66" actual) diameter PEX and a "high head" Taco 008 pump could easily move 3.5 gpm, which of course works out to 105000 btu per hour. The numbers said I could heat my house with 0.75" pipe and a 71 watt pump and by golly it all came true.

Simple on one side of the coin but not so simple on the other. Most gasification hydronic boiler systems, even with storage, do not have constant temp supply water available, nor constant btuh output from the boiler, nor constant btuh demand. As boiler/storage temp drops, with constant gpm flow from the circulator, btuh also drops. Or, as deltaT closes on storage charging, the boiler will idle unless gpm flow increases. And more permutations.

On the other hand, this also is true:

Foolishly insisting arbitrarily that bigger is better will necessarily lead to wasting money on pipe that is too big, a pump that is too big, or both.

Which really means that while

, as any variable changes, another point on the graph applies. Which also means, that a person needs to understand well the hydronics of the person's system and wisely choose the best pump size, circulator size, and circulator type -- blindly picking big or small is bound to result in failure of the system to perform to requirements or excessive cost, or both.It's all a simple and most straightforward graphical solution to very straightforward engineering problem.

We agree completely -- the devil is in the details.

maple1

Minister of Fire

Just a bit sideways: how much of an impact does the 'straightness' , or bending, of a 300ft. stretch of pex impact head loss? That is, how much would be lost pumping through say a 300ft coil, as opposed to having the 300ft. unrolled and laid straight? I don't recall reading on here yet the head impact of a lot of pex bends or coils.

heaterman

Minister of Fire

Back to basics to answer your question...........The fundamental thing that has to be ascertained is ho much your system is able to drop the temp supply/return. If you are working with a 30* delta T you can drop the required flow rate 50%. If you can configure your storage vertically it will help a lot to get good stratification and keep return temp as low as possible to the boiler. Try to arrange the boiler and system supply on the top and the same for both returns on the bottom.

One other anecdotal bit if info. I all the years I have been doing this line of work I have never heard a customer utter the words, "Gee.... I wish I hadn't made the _____ so big."

Taxidermists system is a classic example of trying to overcome undersized tubing with horsepower. It becomes a vicious circle until you wind up burning out pumps and destroying impellers.

Keeping flow rates around 6-8gpm with 1" will avoid most pumping and head problems. 1-1/4 is good to about 15 and 1-1/2 will do around 22gpm without crossing the magic 4 feet per second water velocity.

Just sayin'.

One other anecdotal bit if info. I all the years I have been doing this line of work I have never heard a customer utter the words, "Gee.... I wish I hadn't made the _____ so big."

Taxidermists system is a classic example of trying to overcome undersized tubing with horsepower. It becomes a vicious circle until you wind up burning out pumps and destroying impellers.

Keeping flow rates around 6-8gpm with 1" will avoid most pumping and head problems. 1-1/4 is good to about 15 and 1-1/2 will do around 22gpm without crossing the magic 4 feet per second water velocity.

Just sayin'.

BoilerMan

Minister of Fire

Wow, ewd and Heaterman both have good points.

If a system can be designed to provide a 30

then you can do it with "1 inch" and a "small" Taco 008, however, if you are reaching the high limit temp of storage then the 30

then you can do it with "1 inch" and a "small" Taco 008, however, if you are reaching the high limit temp of storage then the 30

may not be plauaible......... However this is assuming that the boiler is still putting out it's arted BTU....... which it shouldn't be if you are reaching the high limit of stoage....... meaning you shouldn't have just loaded it when the tank is above 170 or something. I must admit, I'd use "1-1/4" and still get away with the 008!

may not be plauaible......... However this is assuming that the boiler is still putting out it's arted BTU....... which it shouldn't be if you are reaching the high limit of stoage....... meaning you shouldn't have just loaded it when the tank is above 170 or something. I must admit, I'd use "1-1/4" and still get away with the 008!

Just more thoughts....

If a system can be designed to provide a 30

then you can do it with "1 inch" and a "small" Taco 008, however, if you are reaching the high limit temp of storage then the 30

then you can do it with "1 inch" and a "small" Taco 008, however, if you are reaching the high limit temp of storage then the 30

may not be plauaible......... However this is assuming that the boiler is still putting out it's arted BTU....... which it shouldn't be if you are reaching the high limit of stoage....... meaning you shouldn't have just loaded it when the tank is above 170 or something. I must admit, I'd use "1-1/4" and still get away with the 008!

may not be plauaible......... However this is assuming that the boiler is still putting out it's arted BTU....... which it shouldn't be if you are reaching the high limit of stoage....... meaning you shouldn't have just loaded it when the tank is above 170 or something. I must admit, I'd use "1-1/4" and still get away with the 008!Just more thoughts....

ewdudley

Minister of Fire

Wow, ewd and Heaterman both have good points.

If a system can be designed to provide a 30then you can do it with "1 inch" and a "small" Taco 008, however, if you are reaching the high limit temp of storage then the 30

may not be plauaible......... However this is assuming that the boiler is still putting out it's arted BTU....... which it shouldn't be if you are reaching the high limit of stoage....... meaning you shouldn't have just loaded it when the tank is above 170 or something. I must admit, I'd use "1-1/4" and still get away with the 008!

Just more thoughts....

Yes we do, and I don't see much disagreement. Once you get up over 4 ft per second or so the increase in amount of power needed to increase flow rate gets very discouraging. And with or without the supposed forthcoming era of cheap natural gas, I think it's fair to assume the residential electricity customer never see a collapse in the price of electricity, so power consumption over the long haul is important. So bigger pipe will always save energy, but I'm saying at some point the cost of bigger pipe couldn't possibly save enough electricity to pay for itself, especially if the required flow was overestimated to begin with.

As I was saying above, need to look at strategies for guaranteeing that water returning to the bottom of storage is as cool as possible. A diverting valve or a buffer/hydronic separator are two good techniques. With good return-to-storage temperature control you'll have good storage stratification, which will provide enough deltaT for a successful remote-storage configuration.

I used to worry about the end-of-burn, hot-storage, boiler idling problem, but now when return temperature gets hot I just shutdown the draft fan with a latched relay and let the fire go out. The more charcoal there is left over, the easier it is to start the next fire.

heaterman

Minister of Fire

All the above being said:

I find that nearly all hydronic systems are over pumped. It's the American way.

Classic example from a small commercial system we overhauled two years ago. ....One of the zones in the building had approximately 30 Trane classroom style hydronic cabinets on it. These were fan forced coils rated for about 12-20,000 depending on the size of the room so we only needed 2GPM or less @ a 20* drop to get rated capacity.

Zone piping consisted of 2.5" copper tube branching progressively smaller all the way down to 3/4 feeding each of the heaters. The circulator pump, which ran 24-7 during the heating season was a Taco 1900 series 3HP that was rated 70GPM/70ft of head at peak efficiency. Measured supply/return temp drop was 5 degrees or less depending on how many units were calling. I never observed a split temp greater than that in all the years I serviced that building.Longest round trip was over 600'.

We replaced that 3HP Taco with a Wilo 1.5x40 variable speed pump which will do about 1.25HP maximum, dialed it in to 28ft of head and let it rip. I found that in order to get a 20* drop we had to crank the Wilo back even more. It now runs at only 19 feet of head. As the valves in each heating unit open, the VS pump just kicks up a notch to maintain the desired head. All the classrooms heat like a dream. We dropped the wattage to run that zone from 5500 to 780.

I find that nearly all hydronic systems are over pumped. It's the American way.

Classic example from a small commercial system we overhauled two years ago. ....One of the zones in the building had approximately 30 Trane classroom style hydronic cabinets on it. These were fan forced coils rated for about 12-20,000 depending on the size of the room so we only needed 2GPM or less @ a 20* drop to get rated capacity.

Zone piping consisted of 2.5" copper tube branching progressively smaller all the way down to 3/4 feeding each of the heaters. The circulator pump, which ran 24-7 during the heating season was a Taco 1900 series 3HP that was rated 70GPM/70ft of head at peak efficiency. Measured supply/return temp drop was 5 degrees or less depending on how many units were calling. I never observed a split temp greater than that in all the years I serviced that building.Longest round trip was over 600'.

We replaced that 3HP Taco with a Wilo 1.5x40 variable speed pump which will do about 1.25HP maximum, dialed it in to 28ft of head and let it rip. I found that in order to get a 20* drop we had to crank the Wilo back even more. It now runs at only 19 feet of head. As the valves in each heating unit open, the VS pump just kicks up a notch to maintain the desired head. All the classrooms heat like a dream. We dropped the wattage to run that zone from 5500 to 780.

heaterman

Minister of Fire

Take it from me.........get 1 1\4 I was sold 1" for a 300' run and i am using a taco 013 and the pump cavates bad trying to force the water thru the 1"

Taxi. Have you ever measured the supply/return temp difference at the boiler when everything is calling for heat? If it's less than 10-15* you could probably drop to something like a 0010 Taco or even something in the range of a Wilo Star21 S or 15-58 Grunt.

Just a thought.

Armaton

Member

In Rob's, (Taxidermists) case, I think it's the logistics of trying to push 205KBTUh through 1" line to his storage 150' from his boiler that is causing his problem. If his storage was right next to his boiler 1 1/4" pipe to transfer all that heat would work, then 1" pex to the house to satisfy zones probably would be ok. Of course thats assuming his house doesn't need more than 100KBTUh. Or am I misunderstanding the setup?

Brandon

Brandon

taxidermist

Minister of Fire

Yes thats right BrandonIn Rob's, (Taxidermists) case, I think it's the logistics of trying to push 205KBTUh through 1" line to his storage 150' from his boiler that is causing his problem. If his storage was right next to his boiler 1 1/4" pipe to transfer all that heat would work, then 1" pex to the house to satisfy zones probably would be ok. Of course thats assuming his house doesn't need more than 100KBTUh. Or am I misunderstanding the setup?

Brandon

Rob

- Status

- Not open for further replies.

Similar threads

- Replies

- 0

- Views

- 1K

- Replies

- 6

- Views

- 2K

- Replies

- 2

- Views

- 3K