Hi all. I am new to building a hearth. I have followed this website and read in the forums to get as far as I have in my planning.Thanks for all the good info. Now I am ready to build.

I am putting a hearth into a corner over a floor of 2x8 joists. The floor is built on top of a short stud wall on the sill of the poured concrete foundation for this single story building. I have several questions.

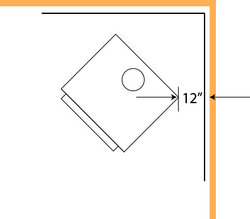

First, regarding setbacks of stove from walls, is the setback a measurement of setback from the closest combustible part of the wall or the final wall surface? I have sheetrocked wood stud walls. I plan to place metal studs over the sheetrock and fill the voids with 3 inch thick rockwool batts, then cover this with 1/2 inch cement board, then a mortar bed and slate or other stone facing. This generally follows the good example given in the articles about a finished hearth. I plan to leave air gaps at the bottom of each wall over a 2 foot span closest to the stove sides/corners. My plan is, hopefully, to be able to count the 5 inches of fire resistant material over the sheetrock wall surface and leave only 3 additional inches between the final slate surface and the metal of the stove sides/corners to achieve the 8 inch minimum setback.

Next, I plan to build the hearth floor in similar fashion, but deeper. I will be using wood joists to bear the weight on the floor of thick cobblestones and the stove. The floor will be shielded by rockwool, cement board, mortar as well as the gap under the stove due to legs and the firebricks and ash in the firebox. This isn't reaslly a question, just informational.

Third, an actual question. In order to provide better support for the floor joists to bear all this new load I plan to add a 4x8 beam diagonally under the joists across the approximate midpoint of the hearth and stove mass. It will not have any posts along its length, but will be supported by the concrete foundation walls. Does this sound like an adequate structural amendment to my building for this corner hearth?

Thanks for your opinions and suggestions.

I am putting a hearth into a corner over a floor of 2x8 joists. The floor is built on top of a short stud wall on the sill of the poured concrete foundation for this single story building. I have several questions.

First, regarding setbacks of stove from walls, is the setback a measurement of setback from the closest combustible part of the wall or the final wall surface? I have sheetrocked wood stud walls. I plan to place metal studs over the sheetrock and fill the voids with 3 inch thick rockwool batts, then cover this with 1/2 inch cement board, then a mortar bed and slate or other stone facing. This generally follows the good example given in the articles about a finished hearth. I plan to leave air gaps at the bottom of each wall over a 2 foot span closest to the stove sides/corners. My plan is, hopefully, to be able to count the 5 inches of fire resistant material over the sheetrock wall surface and leave only 3 additional inches between the final slate surface and the metal of the stove sides/corners to achieve the 8 inch minimum setback.

Next, I plan to build the hearth floor in similar fashion, but deeper. I will be using wood joists to bear the weight on the floor of thick cobblestones and the stove. The floor will be shielded by rockwool, cement board, mortar as well as the gap under the stove due to legs and the firebricks and ash in the firebox. This isn't reaslly a question, just informational.

Third, an actual question. In order to provide better support for the floor joists to bear all this new load I plan to add a 4x8 beam diagonally under the joists across the approximate midpoint of the hearth and stove mass. It will not have any posts along its length, but will be supported by the concrete foundation walls. Does this sound like an adequate structural amendment to my building for this corner hearth?

Thanks for your opinions and suggestions.