I have a Seton W-130 and a propane 225kBtu for a 3700 sqft off grid house at 9000ft

Since the house is off grid, I am trying to minimize electricity - shut off as many circulator as possible.

The Seton cycles on and off many times during the transitional periods (60 degree days and 30 degree nights).

So, I would like to add a storage tank to the system.

Currently the Seton uses a flat plate exchanger to pre-heat the DHW and then keep the existing gas boiler warm to minimize propane use and to use existing zone controls.

There are three zones of radiant heating for the house.

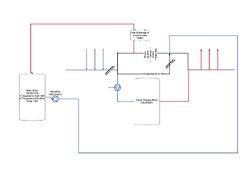

I was planning on building a tank like this

Then I was going to use 3/4" L type copper for the heat exchange - 200 ft top to bottom for the Seton and bottom to top for the heating.

I will probably add solar collectors later.

Questions

1. Tank storage location - Seton is in garage and propane boiler and DHW 40 gal tank in basement. I would like to have the tank in the garage with the Seton. Is there any convection issues with the tank one floor above the propane boiler?

2. Tank structure - is anyone using a plywood tank with and EPDM liner with success?

3. pH values - should the pH for the tank be in the range of 8.2 to 8.9 for the copper Hx?

4. Has anyone used KiTec (Pex) as a successful water to water heat exchanger? If so, is about 3x the length of copper required?

5. How do I minimize the electricity requirements of the system? Can I avoid the always on circulator pumps without using a differential controller?

6. Any additional suggestions would be appreciated.

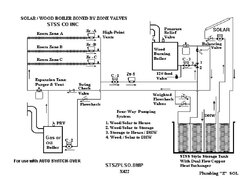

It seems that the ultimate setup is the tank system from Sven at STSS - Does anyone use this system?

Thanks,

Steve

Since the house is off grid, I am trying to minimize electricity - shut off as many circulator as possible.

The Seton cycles on and off many times during the transitional periods (60 degree days and 30 degree nights).

So, I would like to add a storage tank to the system.

Currently the Seton uses a flat plate exchanger to pre-heat the DHW and then keep the existing gas boiler warm to minimize propane use and to use existing zone controls.

There are three zones of radiant heating for the house.

I was planning on building a tank like this

Then I was going to use 3/4" L type copper for the heat exchange - 200 ft top to bottom for the Seton and bottom to top for the heating.

I will probably add solar collectors later.

Questions

1. Tank storage location - Seton is in garage and propane boiler and DHW 40 gal tank in basement. I would like to have the tank in the garage with the Seton. Is there any convection issues with the tank one floor above the propane boiler?

2. Tank structure - is anyone using a plywood tank with and EPDM liner with success?

3. pH values - should the pH for the tank be in the range of 8.2 to 8.9 for the copper Hx?

4. Has anyone used KiTec (Pex) as a successful water to water heat exchanger? If so, is about 3x the length of copper required?

5. How do I minimize the electricity requirements of the system? Can I avoid the always on circulator pumps without using a differential controller?

6. Any additional suggestions would be appreciated.

It seems that the ultimate setup is the tank system from Sven at STSS - Does anyone use this system?

Thanks,

Steve