I've piped out the supply and return headers on my vertical 1000 gallon tank and the only thing left is to think about the radiant floor in the boilerhouse. I put a single loop of 1/2" PEX into the slab when I built the place - total length is about 140 feet, more or less. So I was thinking that for stratification purposes, I might be able to use an existing 3/4" tapping to pull water from near the bottom of the tank, pass it through a thermostatic valve and a circ and return it via the 2" return header at the bottom of the tank. The total water volume between the two tappings is about 130 gallons. Also, I should mention that the boilerhouse is fairly well insulated, and I plan to add more insulation later on. Currently it has 2" blueboard (XPS) outside the studs and rafters, with nothing in the 2x4 stud bays. 3.5" XPS under the slab and 3" around the perimeter and 3" x 3' wing insulation as well. Quite surprisingly, it has been above freezing in the boilerhouse with just a 900W electric heater going, even though it has been -15 at times recently. In BTU/HR, this is only 3000ish BTU/HR.

My logic is that if I assume the minimum bottom tank temp is 100 degrees, then I should be able to harvest the energy at the bottom of the tank for the floor. FWIW, I'm not planning to heat the boilerhouse to normal temperatures - keeping it safely above freezing is the goal.

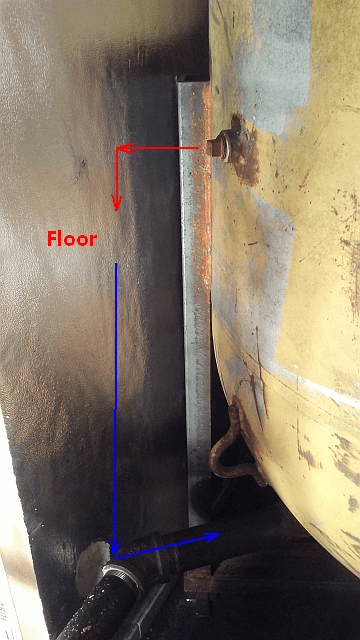

A little picture might help:

Where "Floor" is in the above picture, insert a thermostatic valve, circ and the PEX floor loop. The alternative would be to pull hot water from the tank's supply header, and mix that down. But my thought at the moment is that flow will circulate through the entire tank. Maybe it doesn't matter at all with the kind of flow rates and vertical-ness of the tank?

One of the facts which might kill this idea is the way the thermostatic valves work. I believe they need a certain temp differential from hot to mix ports to work correctly. But I'm quite new at this, and thus cannot say for sure.

All suggestions welcomed. Thanks in advance!

My logic is that if I assume the minimum bottom tank temp is 100 degrees, then I should be able to harvest the energy at the bottom of the tank for the floor. FWIW, I'm not planning to heat the boilerhouse to normal temperatures - keeping it safely above freezing is the goal.

A little picture might help:

Where "Floor" is in the above picture, insert a thermostatic valve, circ and the PEX floor loop. The alternative would be to pull hot water from the tank's supply header, and mix that down. But my thought at the moment is that flow will circulate through the entire tank. Maybe it doesn't matter at all with the kind of flow rates and vertical-ness of the tank?

One of the facts which might kill this idea is the way the thermostatic valves work. I believe they need a certain temp differential from hot to mix ports to work correctly. But I'm quite new at this, and thus cannot say for sure.

All suggestions welcomed. Thanks in advance!