maple1

Minister of Fire

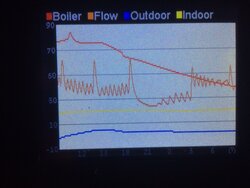

It sure would be helpful for one of the "engineers" to Explain the how's and whys of outdoor reset with indoor feedback with respect to being drawn from storage, system requirements ect. If John can run his house down to the stick your finger in it temps, as I have witnessed, I'm all ears for some real information. For me, I'm expanding on radiation to lower system temp requirements and flow then install odr with indoor feedback

What do you have now for radiation? And wondering if you've tried letting storage temps drop until your house starts losing temp to see what that point really is for your situation? (Might have to do that multiple times to get a better idea where that point is). It was a gradual thing for me, getting to the lows I see now.

I have an iron ring on my finger & degree on my wall, but it had nothing to do with this stuff, and I steered a slightly different course so don't have a stamp to go with it anyway. So afraid I'm out for that - lol.

.

.