I'm having trouble getting the air out of my system. I'm sure things aren't ideal for doing this. High on the list is no vents on the distribution piping. I guess that's the trend nowadays-all the original system had and has is a Taco air scoop. This air scoop is on the supply header, but AFTER the thermomix valve. The supply header then goes to the distribution zones and then to the buffer tank. There are air vents (Hy Vents) on the air scoop and on top of the buffer tank.

It'll be tough to dig around and try to sweat in air vents in the distribution piping.

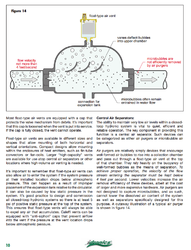

I guess I could put another air separator (non-air scoop) after the tank and before the supply header.

I'm visualizing big bubbles of air that won't come down easily. They float up and there are no vents there. Maybe I'm visualizing wrong.

There are drain valves on the supply side of the return-pumping distribution pumps that I tried bleeding from this morning, zone by zone, using the fill valve, but I don't think it did much good.

I'm hoping that over time the bubbles might travel to the air scoop vent and tank vent, but I don't know.

Is there no substitute for having valves at the high points?

I don't want to mess up my nice new pumps; they're sounding quite gravely.

Thanks for any tips.

It'll be tough to dig around and try to sweat in air vents in the distribution piping.

I guess I could put another air separator (non-air scoop) after the tank and before the supply header.

I'm visualizing big bubbles of air that won't come down easily. They float up and there are no vents there. Maybe I'm visualizing wrong.

There are drain valves on the supply side of the return-pumping distribution pumps that I tried bleeding from this morning, zone by zone, using the fill valve, but I don't think it did much good.

I'm hoping that over time the bubbles might travel to the air scoop vent and tank vent, but I don't know.

Is there no substitute for having valves at the high points?

I don't want to mess up my nice new pumps; they're sounding quite gravely.

Thanks for any tips.