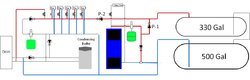

I am plumbing into an existing propane boiler system with an econoburn 150 and wish to keep the existing setup as much as possible. Below is the concept I am considering for achieving this. It is essentially a parallel flow setup. During wood heating or thermal storage discharge, pump p-1 (controlled by boiler) and pump p-2 (thermostat/aquastat controlled) will be used. I expect it to work as follows:

1) Zone Heating and DHW

P-1 and P-2 are operating with most of the flow directed towards the zone valves. However some flow will go to the thermal storage tanks.

2) Thermal Storage Charging

P-1 is operating and P-2 is off. All flow will go to the thermal storage tank. Check valves and zone valves will prevent flow into the rest of the system.

3) Thermal Storage Discharging to zone valves and DHW

P-2 is operating and P-1 is off (no boiler heat) . Flow will reverse through the tanks and flow through to the zone valves.

4) Propane Backup

Operates as it presently does when thermal storage and wood heating are not available

I would appreciate any recommendations on how to improve this system.

1) Zone Heating and DHW

P-1 and P-2 are operating with most of the flow directed towards the zone valves. However some flow will go to the thermal storage tanks.

2) Thermal Storage Charging

P-1 is operating and P-2 is off. All flow will go to the thermal storage tank. Check valves and zone valves will prevent flow into the rest of the system.

3) Thermal Storage Discharging to zone valves and DHW

P-2 is operating and P-1 is off (no boiler heat) . Flow will reverse through the tanks and flow through to the zone valves.

4) Propane Backup

Operates as it presently does when thermal storage and wood heating are not available

I would appreciate any recommendations on how to improve this system.