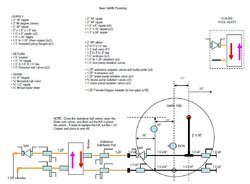

I have a Garn that is in need of getting hooked up. My head keep spinning with all the different options on pipe layouts.

The garn is in its own building. The Garn will be heating my shop with and apartment above it. The shop is all radiant heat in slab with possibly two zones. The apartment is one kitchen/ living room radiant on one zone above the shop and bath/ bed in the attic of the garage with all radiant heat on one zone.

I will be building a house in the future on the other side of the Garn shed and use the Garn to heat it. I also would like to tie a waist oil boiler into the system in the Garn shed also.

Not sure if I am going to put the DHW in with a side arm and have my primary loop run through it when something is calling for heat or put it on its own Zone. Seems like you dont want to agitate the water in the garn any more than necessary so it can stratisfy more efficient.

I plan on doing all the work myself. I am after others opinions on what would be the simplest/ most efficient set up. I am thinking of zoning with valves and using delta T circs. with a bumble bee on the primary?

Any advice on pipe layout would be appreciated.

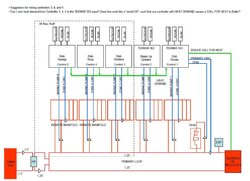

The garn is in its own building. The Garn will be heating my shop with and apartment above it. The shop is all radiant heat in slab with possibly two zones. The apartment is one kitchen/ living room radiant on one zone above the shop and bath/ bed in the attic of the garage with all radiant heat on one zone.

I will be building a house in the future on the other side of the Garn shed and use the Garn to heat it. I also would like to tie a waist oil boiler into the system in the Garn shed also.

Not sure if I am going to put the DHW in with a side arm and have my primary loop run through it when something is calling for heat or put it on its own Zone. Seems like you dont want to agitate the water in the garn any more than necessary so it can stratisfy more efficient.

I plan on doing all the work myself. I am after others opinions on what would be the simplest/ most efficient set up. I am thinking of zoning with valves and using delta T circs. with a bumble bee on the primary?

Any advice on pipe layout would be appreciated.