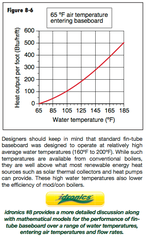

I have an 8ft section of BB in my upstairs bathroom. That puts out 500/600btu's per ft at 175f water? 4/4500btu's of out put? If i run 135f water thru it, whats my btu output going to be? Just a rough idea, it may vary a bit.

The reason for this question is my builder/installer, nearly two decades ago, installed this BB in my upstairs bathroom. But, it's piped into my 1st floor zone. So during the day and night, setback T-stat allows bathroom to cool off pretty good. It's a good sized bathroom, has washer/dryer in it. What i've been thinking about is tying this BB into my radiant floor loop, that serves my kitchen. There is an extra connection on the manifold. Be a fairly easy thing to accomplish. That would give me a continuous flow into bathroom, 24/7. The room is on the west side of house, and can get cooled off pretty easily. I thought about putting a panel rad or cast iron rad in there, but would like to try this first.

Any thoughts?

The reason for this question is my builder/installer, nearly two decades ago, installed this BB in my upstairs bathroom. But, it's piped into my 1st floor zone. So during the day and night, setback T-stat allows bathroom to cool off pretty good. It's a good sized bathroom, has washer/dryer in it. What i've been thinking about is tying this BB into my radiant floor loop, that serves my kitchen. There is an extra connection on the manifold. Be a fairly easy thing to accomplish. That would give me a continuous flow into bathroom, 24/7. The room is on the west side of house, and can get cooled off pretty easily. I thought about putting a panel rad or cast iron rad in there, but would like to try this first.

Any thoughts?