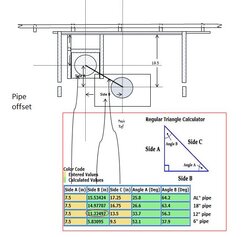

I have used the charts to figure that I can use a 12" piece of pipe between the 45s, move the cathedral box 3/4" closer to peak line and hit the stove outlet center line dead center (theoretically). Been doing some hypoten-using  .

.

Unfortunately DSP does not offer a 30. I ordered some 45 DSPs for cheap off Amazon. Just ordered the rest of my pipe from Lowes.

.

.Unfortunately DSP does not offer a 30. I ordered some 45 DSPs for cheap off Amazon. Just ordered the rest of my pipe from Lowes.

Last edited by a moderator:

...

...