After many, many hours of thinking, planning, and the occasional headache... my project has finally started. For the next few weeks I will be completing my build and install of my new wood stove. I'm a computer programmer by day, but enjoy carpentry (especially furniture making), and thought installing a new stove would be an exciting project to undertake. To start, I'll show you some of the plans I drafted up on the computer. I have some other plans in my head and on some scrap paper, but wanted to make these on the computer to make sure I follow all the minimum requirements and have the computer double-check my measurements and computations.

A little background. The stove is a Hearthstone Heritage Soapstone stove. It's going in the corner in our family room. I'm building a raised hearth and partially stoned back wall with mantel (I may wait on this until a later date as my clearances are already greater then needed to the combustible drywall).

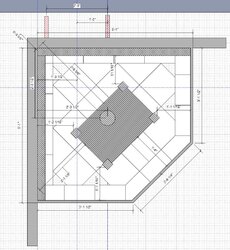

So, here are the plans. I'll post some pictures this evening or tomorrow of the actual space. I'm going to try and document as much as possible to help those who would like to undertake a task like this. Hope you all enjoy!

A little background. The stove is a Hearthstone Heritage Soapstone stove. It's going in the corner in our family room. I'm building a raised hearth and partially stoned back wall with mantel (I may wait on this until a later date as my clearances are already greater then needed to the combustible drywall).

So, here are the plans. I'll post some pictures this evening or tomorrow of the actual space. I'm going to try and document as much as possible to help those who would like to undertake a task like this. Hope you all enjoy!