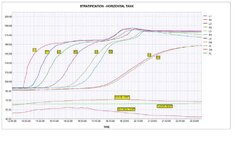

Stratification in a horizontal tank is a frequent question. Attached is a chart which shows charging stratification performance in my 1000 gal pressurized LP storage tank. The chart shows that stratification is quite dramatic. This is a static charge, that is, no hot water was drawn from the tank during the charging process.

The tank is installed in my shop and is insulated to about R-30 (6"+ of fiberglass plus 2" of foam). Hot water supply is 1-1/4" supply line to a 2" horizontal inlet placed on the left end of the tank and 6" down from the top. Cold water return is from a 2" horizontal outlet to 1-1/4" return line placed on the left end of the tank and 6" up from the bottom. The tank is 36" diameter and 19' long.

Eight DS19B20 sensors are fixed to the exterior of the tank, 4 on each end and placed on the top, 9" down from the top, 18" down from the top, 27" down from the top, and on the bottom. The sensors are fixed with aluminum tape to the metal tank and fully covered with the tank insulation.

L1 = top sensor on the left end of the tank; R1 - top sensor on the right end of the tank; etc. Also shown are inside, outside and floor temperatures.

I did not bring the tank up to the maximum possible charge (190F top to bottom), although I have done that it in the past. First boiler fueling was at 12:43 hours and the last boiler fueling was at 18:00 hours. I burned a total of 148 pounds of wood, dry pine/aspen mix. I added wood every 60-90 minutes to maintain a high burn; the Tarm did not idle at any time during the charging process; the circulator is a Grundfos 15-58 on Low speed. Boiler return water protection was maintained between 140-155F. Stack temperature ranged between approximately 375-450F.

There appears to be about a 15-30 minute lag between the time that the temperature begins to rise on the left end of the tank (supply/return side) and the time the temperature begins to rise on the right end of the tank 19' away. But all in all, it appears that very little mixing occurs in the charging process.

Your comments and evaluation are appreciated.

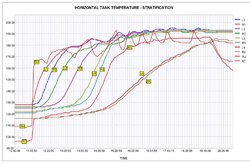

The tank is installed in my shop and is insulated to about R-30 (6"+ of fiberglass plus 2" of foam). Hot water supply is 1-1/4" supply line to a 2" horizontal inlet placed on the left end of the tank and 6" down from the top. Cold water return is from a 2" horizontal outlet to 1-1/4" return line placed on the left end of the tank and 6" up from the bottom. The tank is 36" diameter and 19' long.

Eight DS19B20 sensors are fixed to the exterior of the tank, 4 on each end and placed on the top, 9" down from the top, 18" down from the top, 27" down from the top, and on the bottom. The sensors are fixed with aluminum tape to the metal tank and fully covered with the tank insulation.

L1 = top sensor on the left end of the tank; R1 - top sensor on the right end of the tank; etc. Also shown are inside, outside and floor temperatures.

I did not bring the tank up to the maximum possible charge (190F top to bottom), although I have done that it in the past. First boiler fueling was at 12:43 hours and the last boiler fueling was at 18:00 hours. I burned a total of 148 pounds of wood, dry pine/aspen mix. I added wood every 60-90 minutes to maintain a high burn; the Tarm did not idle at any time during the charging process; the circulator is a Grundfos 15-58 on Low speed. Boiler return water protection was maintained between 140-155F. Stack temperature ranged between approximately 375-450F.

There appears to be about a 15-30 minute lag between the time that the temperature begins to rise on the left end of the tank (supply/return side) and the time the temperature begins to rise on the right end of the tank 19' away. But all in all, it appears that very little mixing occurs in the charging process.

Your comments and evaluation are appreciated.