Hot Water Storage

- Thread starter Eric Johnson

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

keyman512us

Member

Here's something you asked earlier that I missed Eric:

The part you are missing is this: At 5-10k btu's what is your transfer media? A: (air)...what you want to do is tranfer heat from water to water...big difference! (more heat transfer quicker). Your radiator idea for heat transfer is a good idea Eric...(it got me thinking). I'm no engineer on paper but... the firing rate of your boiler with the imersed radiator will work with the tank.

To answer your previous question...About freeze up protection? I have a second circulator tied into the "incoming loop"...using a check valve loop and a simple control circuit. I have an outside temperature sensor to "engage" the circulator. The way it's setup is this: If the boiler temperature drops below 140 the "main" circulator shuts off (to allow the system to "build back up)...if the outside air temp is below 27 degrees the second circualtor "cuts in" reversing the flow (instead of drawing hot out of the top....it draws cold from the bottom). The simple thing to do would be to fill the system with glycol...but I don't want to waste any or spill any if I make changes to the system. Not going to spend major dollars on something the "smoke zealots are "out gunning for".

Good luck with your system...keep us posted!

P.S. ....If that huge cistern were in my basement, when "pouring the wall" I would make provisions to allow "for more water" (a couple pipes on the bottom and one at the top "capped" for future use)...leave yourself some "value added options".

Maybe I’m looking at the wrong information, but cast iron rads are rated at between 5,000 and 10,000 btus each, which isn’t much when you’re trying to get to 200,000 btus per hour. (I must be missing something

The part you are missing is this: At 5-10k btu's what is your transfer media? A: (air)...what you want to do is tranfer heat from water to water...big difference! (more heat transfer quicker). Your radiator idea for heat transfer is a good idea Eric...(it got me thinking). I'm no engineer on paper but... the firing rate of your boiler with the imersed radiator will work with the tank.

To answer your previous question...About freeze up protection? I have a second circulator tied into the "incoming loop"...using a check valve loop and a simple control circuit. I have an outside temperature sensor to "engage" the circulator. The way it's setup is this: If the boiler temperature drops below 140 the "main" circulator shuts off (to allow the system to "build back up)...if the outside air temp is below 27 degrees the second circualtor "cuts in" reversing the flow (instead of drawing hot out of the top....it draws cold from the bottom). The simple thing to do would be to fill the system with glycol...but I don't want to waste any or spill any if I make changes to the system. Not going to spend major dollars on something the "smoke zealots are "out gunning for".

Good luck with your system...keep us posted!

P.S. ....If that huge cistern were in my basement, when "pouring the wall" I would make provisions to allow "for more water" (a couple pipes on the bottom and one at the top "capped" for future use)...leave yourself some "value added options".

I like the circulator idea, keyman. I'm going to insulate the living daylight out of the lines and if that doesn't do the trick, I'll rig up the main circulator like you suggest.

Craig straightened me out on the radiator idea. Unless you've got 2,000-degree fire hitting the cast iron, there's not enough heat transfer to make a difference. 190-degree water ain't gonna do the job. I've got a flat plate heat exchanger currently transferring heat from my glycol-based 150,000 btu wood boiler system into the water-based house system, and it does the job just fine, so I'm sure a flat plate will work with the tank. Plus, no water in the tank is displaced by the heat exchanger. When I install the new boiler, I'm going to forget the glycol and pipe it direct.

And I am keeping my options open with the tank. If the 1,000 gallons works like I hope it will, I can build a second, 1,500-gallon tank right next to it, using up the rest of the cistern. Having two tanks would probably be better than one big one.

Thanks for the input. You know I'll post the progress.

Craig straightened me out on the radiator idea. Unless you've got 2,000-degree fire hitting the cast iron, there's not enough heat transfer to make a difference. 190-degree water ain't gonna do the job. I've got a flat plate heat exchanger currently transferring heat from my glycol-based 150,000 btu wood boiler system into the water-based house system, and it does the job just fine, so I'm sure a flat plate will work with the tank. Plus, no water in the tank is displaced by the heat exchanger. When I install the new boiler, I'm going to forget the glycol and pipe it direct.

And I am keeping my options open with the tank. If the 1,000 gallons works like I hope it will, I can build a second, 1,500-gallon tank right next to it, using up the rest of the cistern. Having two tanks would probably be better than one big one.

Thanks for the input. You know I'll post the progress.

keyman512us

Member

Eric:

Eric:

Not to contradict 'Web', you or anyone else here that may a lot of "valuable thoughts"... But you are approaching the situation somewhat in the wrong manner. I'm speaking "from my education on this matter"...which is of the best type of education you can get: First hand,hands on actual operating experience. Here is a couple things (theory for comparison value based on my exp):

Using "my system" as reference: Living area- 1800 sq/ft, 1800sqft ("other") main boiler (oil)110k btus/hr (think of it as "on-demand-instaneous-'on call'...heat SOURCE" )... wood fired boiler 85K btu (think of it as constant fire-long duration...heat SOURCE)...so we have the heating load and (DMHW for two). Why go into detail you say?

The reason is you have to diferentiate between the heat SOURCE and the conveyance/transfer MEDIA (water or air...conductive or convective)...and your end PRODUCT. You start a fire to heat water to heat air...you need to break the whole thing into the simple basic three processes you are dealing with. The fire-Source, the water-Media, keeping your house warm/the hot water we need to enjoy life-the PRODUCT. As anyone with a "mechanical background" will tell you ('HVAC guys'..are a great wealth for the 'theory')..there is no such thing as "Hot or Cold"...only degrees of heat transfer. The hardest transfer if from the fire to the media- water is harder to heat than air (conductive versus convective)...Your boiler is going to do the job wheter you try to store the heat or not. Think of "using that heat" kinda like the way you use electricity, you have to view the heat storage as a "battery". The hardest work is already done by trapping the heat...into the water...and is simple to release because of the stored energy. Webs' analogy of the 2000 degree fire hitting the cast iron is already 'null and void' becuse the boiler already did it for you. You have already "done your homework" even the thought of the propane tank idea (which as a DIRECT method is a good one by the way...something my system uses). Direct vs INDIRECT (with an 'exchager') are both the same efficiency just indirect uses more TIME in the equation. With a boiler setup TIME...needs to be taken into consideration. Direct method with an 'accumulator' tank (120 gallons for mine) once the system is "balanced" I can bring that 120 gallons 'up to temp' from say 58 degrees to 140 in ten minutes. I use both method accumulator-direct, and "Non recoverable" indirect.

The reason I bring this up is this: Try using both the exchanger and the "radiator" in your "storage system". Place the radiator at the bottom of the tank...have the exchanger draw from the top of the tank...and you should get the most "bang for the buck"

"....I'm not even going to describe the concept of a 'runaway ramp' for a wood fired boiler.."

Craig straightened me out on the radiator idea. Unless you’ve got 2,000-degree fire hitting the cast iron, there’s not enough heat transfer to make a difference. 190-degree water ain’t gonna do the job. I’ve got a flat plate heat exchanger currently transferring heat from my glycol-based 150,000 btu wood boiler system into the water-based house system, and it does the job just fine, so I’m sure a flat plate will work with the tank. Plus, no water in the tank is displaced by the heat exchanger.

Eric:

Not to contradict 'Web', you or anyone else here that may a lot of "valuable thoughts"... But you are approaching the situation somewhat in the wrong manner. I'm speaking "from my education on this matter"...which is of the best type of education you can get: First hand,hands on actual operating experience. Here is a couple things (theory for comparison value based on my exp):

Using "my system" as reference: Living area- 1800 sq/ft, 1800sqft ("other") main boiler (oil)110k btus/hr (think of it as "on-demand-instaneous-'on call'...heat SOURCE" )... wood fired boiler 85K btu (think of it as constant fire-long duration...heat SOURCE)...so we have the heating load and (DMHW for two). Why go into detail you say?

The reason is you have to diferentiate between the heat SOURCE and the conveyance/transfer MEDIA (water or air...conductive or convective)...and your end PRODUCT. You start a fire to heat water to heat air...you need to break the whole thing into the simple basic three processes you are dealing with. The fire-Source, the water-Media, keeping your house warm/the hot water we need to enjoy life-the PRODUCT. As anyone with a "mechanical background" will tell you ('HVAC guys'..are a great wealth for the 'theory')..there is no such thing as "Hot or Cold"...only degrees of heat transfer. The hardest transfer if from the fire to the media- water is harder to heat than air (conductive versus convective)...Your boiler is going to do the job wheter you try to store the heat or not. Think of "using that heat" kinda like the way you use electricity, you have to view the heat storage as a "battery". The hardest work is already done by trapping the heat...into the water...and is simple to release because of the stored energy. Webs' analogy of the 2000 degree fire hitting the cast iron is already 'null and void' becuse the boiler already did it for you. You have already "done your homework" even the thought of the propane tank idea (which as a DIRECT method is a good one by the way...something my system uses). Direct vs INDIRECT (with an 'exchager') are both the same efficiency just indirect uses more TIME in the equation. With a boiler setup TIME...needs to be taken into consideration. Direct method with an 'accumulator' tank (120 gallons for mine) once the system is "balanced" I can bring that 120 gallons 'up to temp' from say 58 degrees to 140 in ten minutes. I use both method accumulator-direct, and "Non recoverable" indirect.

The reason I bring this up is this: Try using both the exchanger and the "radiator" in your "storage system". Place the radiator at the bottom of the tank...have the exchanger draw from the top of the tank...and you should get the most "bang for the buck"

"....I'm not even going to describe the concept of a 'runaway ramp' for a wood fired boiler.."

keyman512us

Member

What happened to Reggie? lol

Reggie: If your are still following the thread check in with us please... Did you buy the TARM solo unit???

Web? (Or anyone else? ) ") Do you have any contacts at TARM? Long range I'm thinking of a gassification boiler for "inside the house"...lol

Eric? What specific model is your new boiler? Any links?

Reggie: If your are still following the thread check in with us please... Did you buy the TARM solo unit???

Web? (Or anyone else? ) ") Do you have any contacts at TARM? Long range I'm thinking of a gassification boiler for "inside the house"...lol

Eric? What specific model is your new boiler? Any links?

keyman512us

Member

Eric:

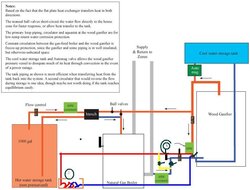

I like this diagram you came up with...here's my idea to "tweak it":

Change control #1 to a "triple acting aquastat" (so once the gas boiler is up to temp it diverts the hot water to the radiator #2 at the bottom of your tank). The valving/piping allows for "two additional modes"...(long and short duration heat storage...kinda valueble if you see a 'cold snap' in the forecast) ")

Nice design work...I'm not to handy with the computer...lol

I like this diagram you came up with...here's my idea to "tweak it":

Change control #1 to a "triple acting aquastat" (so once the gas boiler is up to temp it diverts the hot water to the radiator #2 at the bottom of your tank). The valving/piping allows for "two additional modes"...(long and short duration heat storage...kinda valueble if you see a 'cold snap' in the forecast) ")

Nice design work...I'm not to handy with the computer...lol

Attachments

Thanks for the tweak, keyman. I'll have to look this over and figure out what you're suggesting. It's like wiring: I have to look at this stuff long and hard and do some heat scratching before it sinks in. Actually, I have a more recent schematic here:

http://www.nefpexpo.net/thewholeshebang.pdf

On the boiler, I've pretty much decided on the EKO 60, which is a 205K btu/hr gasifier imported from Poland. Similar to the Tarm Solo 60 but cheaper and with some different features. One of my main motivators, aside from the price, is that the EKO will take 24-inch wood, of which I currently have about 20 cords stacked in the backyard and another 20 or so blocked up out in the woods. The Tarm maxes out at 20 inches, so that's a big factor for me. The people I've corresponded with who have EKOs say they operate as advertised: no smoke when they're running and not much tending.

Here's the link to the place I'm getting it from. He's one of the U.S. distributors. New Horizons in West Virginia is the importer.

http://www.cozyheat.net/eko.htm

Dave at cozyheat was extremely helpful in designing the piping scheme. There are things unique to gasifiers that affect the way they're piped and pumped, and I needed it to fit into my current scheme with a minimum of modification. And we were able to do that, so that most of my expense will be in the cost of the boiler, not the piping. Considering the price of copper these days, that's pretty important as well.

If you're thinking about any new boiler, you should check with the Mass. dept of Revenue and see if they offer a tax credit. In NYS, it's $400 if you buy a high efficiency boiler. At 85-90%, wood gasifiers definitely qualify.

http://www.nefpexpo.net/thewholeshebang.pdf

On the boiler, I've pretty much decided on the EKO 60, which is a 205K btu/hr gasifier imported from Poland. Similar to the Tarm Solo 60 but cheaper and with some different features. One of my main motivators, aside from the price, is that the EKO will take 24-inch wood, of which I currently have about 20 cords stacked in the backyard and another 20 or so blocked up out in the woods. The Tarm maxes out at 20 inches, so that's a big factor for me. The people I've corresponded with who have EKOs say they operate as advertised: no smoke when they're running and not much tending.

Here's the link to the place I'm getting it from. He's one of the U.S. distributors. New Horizons in West Virginia is the importer.

http://www.cozyheat.net/eko.htm

Dave at cozyheat was extremely helpful in designing the piping scheme. There are things unique to gasifiers that affect the way they're piped and pumped, and I needed it to fit into my current scheme with a minimum of modification. And we were able to do that, so that most of my expense will be in the cost of the boiler, not the piping. Considering the price of copper these days, that's pretty important as well.

If you're thinking about any new boiler, you should check with the Mass. dept of Revenue and see if they offer a tax credit. In NYS, it's $400 if you buy a high efficiency boiler. At 85-90%, wood gasifiers definitely qualify.

slowzuki

Minister of Fire

I'm following your project with intereset Eric, as I'm going to be hooking my boiler up this summer in a similar fashion. I'm using indirect storage, an insulated bulk milk tank with a copper loop or auto rad based heat exchanger.

The pressurized main loop is pressurized so my boiling point is a bit higher for a bit better heat xfer to the storage. I may put some glycol into the tank too if my heat exchanger is a large enough area. The main problem is you don't need much of a heat exchanger when the tank is cold but once it starts getting close in temp to the boiler you need more and more xfer area.

The pressurized main loop is pressurized so my boiling point is a bit higher for a bit better heat xfer to the storage. I may put some glycol into the tank too if my heat exchanger is a large enough area. The main problem is you don't need much of a heat exchanger when the tank is cold but once it starts getting close in temp to the boiler you need more and more xfer area.

My experience with flat plate heat exchangers is limited to my current setup, which is glycol in the wood boiler and plain water in the house's system. Both are pressurized. My wood boiler temps get up to about 190, and the temp in the gas boiler vessel goes down to about 120 when there's a heavy call for heat. So there's a good heat differential across the exchanger, though the wood boiler temp won't stay nearly that high for long with a big heat demand from the house. But the bottom line is that 95% of the time, my 150,000 btu/hr flat plate heat exchanger is able to get enough heat out of the wood side to comfortably heat my big old house and DHW. Not during extended periods below zero, however. That's below zero in Fahrenheit.

I've never used heat storage, beyond the 50-gallon electric hot water heater and the 30 or so gallons around the gas-fired boiler vessel, but I suspect that a lower heat transfer rate across the heat exchanger at higher storage tank temps would not be a big issue, since (at least the way I have mine diagrammed), the tank charges up over time--basically taking up what the house doesn't. The critical function would seem to be recovering heat from the tank and again, if the water is hot enough, the transfer rate is not as important.

That's just me trying to think this through with no practical experience.

What kind of boiler do you have or thinking of getting, slowzuki?

I've never used heat storage, beyond the 50-gallon electric hot water heater and the 30 or so gallons around the gas-fired boiler vessel, but I suspect that a lower heat transfer rate across the heat exchanger at higher storage tank temps would not be a big issue, since (at least the way I have mine diagrammed), the tank charges up over time--basically taking up what the house doesn't. The critical function would seem to be recovering heat from the tank and again, if the water is hot enough, the transfer rate is not as important.

That's just me trying to think this through with no practical experience.

What kind of boiler do you have or thinking of getting, slowzuki?

Reggie Dunlap

Feeling the Heat

Keyman,

I have not bought the Tarm yet, but I probably will this summer. I've looked pretty hard at the EKO's but I think I'll buy the Tarm Solo 40 for a couple of reasons.

First, Nichols has been importing them for many years and they are only a couple of hours south of me. To me that means long term local support for parts if necessary and no shipping charge for the boiler.

Second, the price I was quoted for the Tarm 40 is not too far from what EKO's website advertises. I'm not sure if it's an apples to apples comparison, but it's close enough.

I think the EKO's are are probably just as good as the Tarm's, but I'm leery of them because they havn't been around very long and no one around here knows anything about them. Most plumbers and heating guys around here are familiar with Tarm. I do wish the Tarm would take 24" wood. I've heated the house with a Hearthstone Mansfield for the last 8 years and never understood why they didn't make it big enough for 24" logs.

Reggie

I have not bought the Tarm yet, but I probably will this summer. I've looked pretty hard at the EKO's but I think I'll buy the Tarm Solo 40 for a couple of reasons.

First, Nichols has been importing them for many years and they are only a couple of hours south of me. To me that means long term local support for parts if necessary and no shipping charge for the boiler.

Second, the price I was quoted for the Tarm 40 is not too far from what EKO's website advertises. I'm not sure if it's an apples to apples comparison, but it's close enough.

I think the EKO's are are probably just as good as the Tarm's, but I'm leery of them because they havn't been around very long and no one around here knows anything about them. Most plumbers and heating guys around here are familiar with Tarm. I do wish the Tarm would take 24" wood. I've heated the house with a Hearthstone Mansfield for the last 8 years and never understood why they didn't make it big enough for 24" logs.

Reggie

Those model numbers are the KW ratings, I think. So an EKO 40 should be about the same size as the Solo 40. You can't go wrong with a Tarm. Better warranty, too.

One thing the EKO does that the Tarm apparently doesn't is allow you to set the fan to run for brief periods during idle, which is supposed to keep the fire going when there's no call for heat. The Tarms will go out if they idle for too long, which means restarting the fire. Other than that, the impression I get from talking to people with both brands is that they work about the same. I think the basic technology is identical.

One of the regular posters at heatinghelp.com, hot rod, is an alternative energy p/h contractor and he has an EKO 40, I believe.

One thing the EKO does that the Tarm apparently doesn't is allow you to set the fan to run for brief periods during idle, which is supposed to keep the fire going when there's no call for heat. The Tarms will go out if they idle for too long, which means restarting the fire. Other than that, the impression I get from talking to people with both brands is that they work about the same. I think the basic technology is identical.

One of the regular posters at heatinghelp.com, hot rod, is an alternative energy p/h contractor and he has an EKO 40, I believe.

slowzuki

Minister of Fire

The problem with tank storage is when your house is not pulling heat, and the tank is near full and you are trying to charge the tank the last bit. It can cause the boiler to overheat. A fellow I know has a 120k BTU unit with a 2000 gal tank and his plumber didn't use enough loops in the storage tank so he has to charge his floor at the same time at the tank during the last stage because his boiler over heats. Once charged though he goes 3-7 days before recharging. I'd like to get him setup with a better system, he currently cracks a bypass valve manually to do this.

I've got a Jetstream boiler, old fashioned rig but sort of similar to the newer ones. The wiki I made, http://en.wikipedia.org/wiki/Jetstream_furnace explains a bit.

I've got a Jetstream boiler, old fashioned rig but sort of similar to the newer ones. The wiki I made, http://en.wikipedia.org/wiki/Jetstream_furnace explains a bit.

Eric Johnson said:if the water is hot enough, the transfer rate is not as important.

That's just me trying to think this through with no practical experience.

What kind of boiler do you have or thinking of getting, slowzuki?

Interesting. Very interesting.

That sounds like quite a rig you've got there, slowzuki. I'm intrigued by your claim that it can burn partially dried wood without smoke. Sort of matches the claims by this manufacturer, whose local sales rep just contacted me, though a post I made at Mother Earth News:

http://www.adobeboiler.com/file.html

They say you can burn partially dried, unsplit wood and only have to clean the ash pan out every two or three months (!). The ash part sounds a little fishy to me. I'll be up in Bangor in a couple of weeks, so maybe I'll scoot over to Hamden and checkitout.

Thanks for the explanation on the problem with charging up the tank that one last little bit. I have a greenhouse to dump excess heat into, so I should be able to get around any problems there, but I can see where that might be a problem in the summer when trying to charge the tank up for DHW. The EKO is supposed to idle well, but the manual has a couple of pages devoted to strategies to avoid overheating, so it's obviously a concern.

I do have a couple of questions for you. First, do you think I can use a flat plate heat exchanger to get heat into the tank, vs. all that copper coil? I mean, we're talking more than 600 feet of the stuff for an 800-gallon tank. There's got to be a cheaper way.

And secondly, you seem to have some knowledge about gasifiers. Any opinion on the Orlan/EKO line?

That sounds like quite a rig you've got there, slowzuki. I'm intrigued by your claim that it can burn partially dried wood without smoke. Sort of matches the claims by this manufacturer, whose local sales rep just contacted me, though a post I made at Mother Earth News:

http://www.adobeboiler.com/file.html

They say you can burn partially dried, unsplit wood and only have to clean the ash pan out every two or three months (!). The ash part sounds a little fishy to me. I'll be up in Bangor in a couple of weeks, so maybe I'll scoot over to Hamden and checkitout.

Thanks for the explanation on the problem with charging up the tank that one last little bit. I have a greenhouse to dump excess heat into, so I should be able to get around any problems there, but I can see where that might be a problem in the summer when trying to charge the tank up for DHW. The EKO is supposed to idle well, but the manual has a couple of pages devoted to strategies to avoid overheating, so it's obviously a concern.

I do have a couple of questions for you. First, do you think I can use a flat plate heat exchanger to get heat into the tank, vs. all that copper coil? I mean, we're talking more than 600 feet of the stuff for an 800-gallon tank. There's got to be a cheaper way.

And secondly, you seem to have some knowledge about gasifiers. Any opinion on the Orlan/EKO line?

slowzuki

Minister of Fire

1) the partly dried wood - burns it fine due to the very turbulent air stream, the catch is the refractory has to get up to temp first so you can't start a burn on wet wood. You start dry on the first rank then the next stack (its loaded in layers) is wet.

2) Re flat plate, if sized big enough it will of course work. I hope to use some old finned baseboards or get the set of coils a fellow has. Still a few hundred bucks in copper. The flat plate means another circulator and I'm really trying to use a few zone valves and only one circulator so if the power fails my ups can run it as long as possible. My manual has 4 or 5 different piping schemes to reduce the number of components and simplify the controls.

The coil my 120k BTU unit calls for is 100 ft of 1" soft copper at 10 gpm or 4 coils of 1/2" finned copper coils, 16 turns in 32 inches, in parallel also at 10 gpm on a 1" header. I will be trying to use some different components. I have access to some truck condensors, it looks like 4 in parallel should be about right. The fins are way larger than needed for immersion but it won't hurt. If that falls through it will be some auto condensors or rads.

3) I looked at the New Horizons and liked what I saw plus the consumables are cheap, could stock up for a few years worth of nozzles with breaking the bank. I suspect there may be some more advanced models available but they have a pretty good controller and solid straight forward construction. My insurance company won't let me put an unlisted appliance in my building unfortunately so that leaves them out of the picture.

2) Re flat plate, if sized big enough it will of course work. I hope to use some old finned baseboards or get the set of coils a fellow has. Still a few hundred bucks in copper. The flat plate means another circulator and I'm really trying to use a few zone valves and only one circulator so if the power fails my ups can run it as long as possible. My manual has 4 or 5 different piping schemes to reduce the number of components and simplify the controls.

The coil my 120k BTU unit calls for is 100 ft of 1" soft copper at 10 gpm or 4 coils of 1/2" finned copper coils, 16 turns in 32 inches, in parallel also at 10 gpm on a 1" header. I will be trying to use some different components. I have access to some truck condensors, it looks like 4 in parallel should be about right. The fins are way larger than needed for immersion but it won't hurt. If that falls through it will be some auto condensors or rads.

3) I looked at the New Horizons and liked what I saw plus the consumables are cheap, could stock up for a few years worth of nozzles with breaking the bank. I suspect there may be some more advanced models available but they have a pretty good controller and solid straight forward construction. My insurance company won't let me put an unlisted appliance in my building unfortunately so that leaves them out of the picture.

Is your Jetstream UL listed, or are you looking at something new?

I think replacement nozzles for the EKO are about $50 each. Do you think they need replacement regularly?

Flat plates are getting cheaper all the time. You can get a pretty big one for under $500. I'm going to try my 150K unit with the 1000-gallon tank and see how it works. If the power goes out, I'm pretty much out of luck anyway, what with all the pumps and fans, etc. on my system. Fortunately, I live in town, so power outages are rare events that typically don't last long. Famous last words.

I used to live up in a small town in the Adirondacks where the power went out all the time. We had a Marathon wood boiler hooked up to an old gravity-feed heating system with a bunch of cast iron rads and big old iron pipe. No power needed on that system--it even had one of those bimetal draft door controls. Just load it with wood and go to bed. It was a sweet setup.

Keyman seems to think that a cast iron rad will work if immersed in a tank. I thought so, but then Craig talked me out of it. A lot of surface area there. I don't know how long the rad would last but if you hooked it up right and kept the oxygen levels down, it might last a good long time. I also thought about using 3/4 or 1" finned baseboard cores, but finally decided to go with what I've got on hand and I know works, which is the fp htx.

I think replacement nozzles for the EKO are about $50 each. Do you think they need replacement regularly?

Flat plates are getting cheaper all the time. You can get a pretty big one for under $500. I'm going to try my 150K unit with the 1000-gallon tank and see how it works. If the power goes out, I'm pretty much out of luck anyway, what with all the pumps and fans, etc. on my system. Fortunately, I live in town, so power outages are rare events that typically don't last long. Famous last words.

I used to live up in a small town in the Adirondacks where the power went out all the time. We had a Marathon wood boiler hooked up to an old gravity-feed heating system with a bunch of cast iron rads and big old iron pipe. No power needed on that system--it even had one of those bimetal draft door controls. Just load it with wood and go to bed. It was a sweet setup.

Keyman seems to think that a cast iron rad will work if immersed in a tank. I thought so, but then Craig talked me out of it. A lot of surface area there. I don't know how long the rad would last but if you hooked it up right and kept the oxygen levels down, it might last a good long time. I also thought about using 3/4 or 1" finned baseboard cores, but finally decided to go with what I've got on hand and I know works, which is the fp htx.

Burn-1

Feeling the Heat

Eric,

While I was looking at the Seton boiler site for one of the other threads I saw that he has some

flat plates for sale. The price and BTU/hr seem right for your plans with the EKO.

Flat plate (toward the middle of the page)

While I was looking at the Seton boiler site for one of the other threads I saw that he has some

flat plates for sale. The price and BTU/hr seem right for your plans with the EKO.

Flat plate (toward the middle of the page)

slowzuki

Minister of Fire

The jetstream is listed, I was looking at something new though too. I started pricing and was able to find some jetstreams still out there.

I get a lot more energy out of 1000 gal than you will because I only need 80 F water for my floor so I can use the whole 200 f to 80 f heat storage. You may find that you want to add more storage to fire less often in the spring or fall (or summer domestic). The only thing I hope to keep going in a power failure is circulation from my storage to my floor. I can keep my building from freezing for probably a week in the middle of winter if I have that pump running even without firing.

I was a bit confusing in my statement about the coils, the baseboard coil would be for my domestic preheating also immersed in the tank.

The nozzles typically need replaced every 4-5 years of regular use in almost every other design. I'm sure theirs is no different. If you save a spare one you can make a mould to cast your own incase they stop importing them. A local fellow casts Jetstream nozzles.

I get a lot more energy out of 1000 gal than you will because I only need 80 F water for my floor so I can use the whole 200 f to 80 f heat storage. You may find that you want to add more storage to fire less often in the spring or fall (or summer domestic). The only thing I hope to keep going in a power failure is circulation from my storage to my floor. I can keep my building from freezing for probably a week in the middle of winter if I have that pump running even without firing.

I was a bit confusing in my statement about the coils, the baseboard coil would be for my domestic preheating also immersed in the tank.

The nozzles typically need replaced every 4-5 years of regular use in almost every other design. I'm sure theirs is no different. If you save a spare one you can make a mould to cast your own incase they stop importing them. A local fellow casts Jetstream nozzles.

Eric Johnson said:Is your Jetstream UL listed, or are you looking at something new?

I think replacement nozzles for the EKO are about $50 each. Do you think they need replacement regularly?

Flat plates are getting cheaper all the time.

Keyman seems to think that a cast iron rad will work if immersed in a tank. I thought so, but then Craig talked me out of it. A lot of surface area there. I don't know how long the rad would last but if you hooked it up right and kept the oxygen levels down, it might last a good long time. I also thought about using 3/4 or 1" finned baseboard cores, but finally decided to go with what I've got on hand and I know works, which is the fp htx.

Thanks Burn 1. That website is a little hard on the old eyeballs, but it's got a lot of good information. I'm going to start off by using the flat plate exchanger that I have. It's a 30-plate, 150K btu model which has worked pretty well for me. We'll see how well it performs on the new system.

That's good advice on the nozzles, slowzuki. I have space for another 1,350 gallons of storage and if the 1,000 gallon tank works out, then it won't be hard to add the additional tank. I think having two separate tanks will offer more flexibility than one big one.

That's an interesting point about your water temps and what it means for heat storage. Am I correct in assuming that by adding a four-way mixing valve to my biggest zone, that I could get by with lower temps in the system and get more out of my tank(s)? That's something I considered before deciding to go with the tank. I've got 11 cast iron rads on one zone.

That's good advice on the nozzles, slowzuki. I have space for another 1,350 gallons of storage and if the 1,000 gallon tank works out, then it won't be hard to add the additional tank. I think having two separate tanks will offer more flexibility than one big one.

That's an interesting point about your water temps and what it means for heat storage. Am I correct in assuming that by adding a four-way mixing valve to my biggest zone, that I could get by with lower temps in the system and get more out of my tank(s)? That's something I considered before deciding to go with the tank. I've got 11 cast iron rads on one zone.

slowzuki

Minister of Fire

Eric I haven't exactly followed your setup but basically traditional rads run intermittently with high temp heat so the last one in the loop will still have enough heat output. Running them longer reduces the high-temp requirment and so does making smaller zones. If you are talking using the 4 way so your circulator runs continuously and your boiler/storage tank just react to the demands from the mixing valve that is a type of approach.

Mixing valves in a technically way waste a bit of the total efficiency in a system, only in that the higher you go above the ultimate temp you need at the rad, more loss occurs in the system and you lose more up the stack. Of course we can only drag out boilers temps down so low before condensing the flue gases, and running super hot water intermittently in rads is just as inefficient as the mixing valve.

If you say need 170 f to heat on your main loop right now continuously, splitting that loop (assuming the first rads in the loop are oversized or are covered to reduce output) and making another parallel loop dropping the heat requirement to say 130 f would really increase the capacity of your thermal battery. You still output the same amount of heat but can get it from a lower temp source. Wish I could explain this in person rather than typing.

A good system would have had the rads sized for their location in the loop. Some old residential systems didn't have this, only covers over rads if the room got too hot while the later rooms froze. If it was accuratly sized in the first place, makes it harder to break the loop, or at least without adding more thermostats and another zone valve or circulator.

Mixing valves in a technically way waste a bit of the total efficiency in a system, only in that the higher you go above the ultimate temp you need at the rad, more loss occurs in the system and you lose more up the stack. Of course we can only drag out boilers temps down so low before condensing the flue gases, and running super hot water intermittently in rads is just as inefficient as the mixing valve.

If you say need 170 f to heat on your main loop right now continuously, splitting that loop (assuming the first rads in the loop are oversized or are covered to reduce output) and making another parallel loop dropping the heat requirement to say 130 f would really increase the capacity of your thermal battery. You still output the same amount of heat but can get it from a lower temp source. Wish I could explain this in person rather than typing.

A good system would have had the rads sized for their location in the loop. Some old residential systems didn't have this, only covers over rads if the room got too hot while the later rooms froze. If it was accuratly sized in the first place, makes it harder to break the loop, or at least without adding more thermostats and another zone valve or circulator.

I've got my hands full just getting the boiler installed and operating and the tank built over the summer, but a four-way valve is one thing I might do in the future. The loop I described is the heating system for the original house, which is an 1865 farmhouse, probably added some time in the early 1900s. Everything's been replumbed at least once since then, probably in the '80s during major renovations. So I don't really know. I do know that if we had continuous circ of 170-degree water through that zone, we'd cook. I'm thinking more like 140 on an average winter day to keep the place toasty. I have two other zones with 2 rads each and an attached greenhouse.

Reggie Dunlap

Feeling the Heat

Here are the Tarm prices if anyone is interested. They have a sale going on until May 15.

Solo 40 140k BTU $6145

Solo 60 198k BTU $6740

After May 15

$6895

$7495

Also there is no sales tax in NH

Solo 40 140k BTU $6145

Solo 60 198k BTU $6740

After May 15

$6895

$7495

Also there is no sales tax in NH

Thanks Reggie. That's useful.

Do you know if that includes shipping? Last time I checked, it did.

If you can get the Solo 60 to take 24-inch wood, I might go the extra $500.

Do you know if that includes shipping? Last time I checked, it did.

If you can get the Solo 60 to take 24-inch wood, I might go the extra $500.

Reggie Dunlap

Feeling the Heat

Burn-1

Feeling the Heat

I saw this on Craigslist earlier today, a free multi-fuel TARM

Free older Tarm multi-fuel

A good score if someone could use it

Free older Tarm multi-fuel

A good score if someone could use it

slowzuki

Minister of Fire

Eric how's your evaluation going? I've vaccumed out the nest and trapped the 5 mice that where in my Jetstream. I've got a photo of it on my blog, http://www.onthefarm.ca/

I've been collecting piping and valves for the plumbing, also busy moving my sawmill before the ground thaws too much.

I've been collecting piping and valves for the plumbing, also busy moving my sawmill before the ground thaws too much.

- Status

- Not open for further replies.

Similar threads

- Replies

- 5

- Views

- 878

- Replies

- 10

- Views

- 2K

- Replies

- 20

- Views

- 872

- Replies

- 8

- Views

- 608