Haha, not my wedding, been married a couple of years now. I have a bunch of info on the boiler on wikipedia and on my webpage

www.onthefarm.ca but the basics are this:

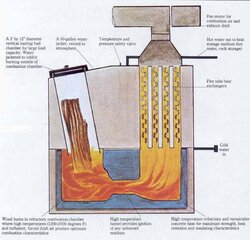

-Water cooled wood chamber, water cooled fire tube boiler.

-Forced and induced draft resulting in slightly positive combustion chamber in use, negative while loading (fd turns off)

-Wood loaded vertical through the top, 40 lb softwood, 60 lb hardwood per loading

-Wood falls down into a refractory combustion chamber where primary combustion and release of gases occurs.

-The combustion zone is blasted by a 100 m/s air jet from a preheated tube, almost always runs with an excess oxygen condition

-The burning continues into a insulated refractory tunnel with adequate length to have mixing of the excess air with any left over particles.

-Upon leaving the tunnel the gasses enter the fire tube heat exchanger and leave.

So advantages over "conventional" gasifiers, burns wetter wood easier but still needs to have the combustion chamber prewarmed by a hot fire. Easy to load, takes up to 40" wood, 36" is the practical limit though. Dry wood can be loaded unsplit once chamber is hot.

Disadvantages? High jet speed ejects fair amount of ash out the stack. Tunnel only lasts 5 years from extremely high temps despite SS fibre reinforcement although it only costs 50$ or so to replace. Pressurized stack needs to be well sealed including taped joints to prevent ash ejection. Water storage is a requirement because no idle controls are fitted. It will auto relight up to a few hours after cutting power due to stored temps but will smoke like a conventional boiler if no power is provided.

There is lots more but thats the gist of it.