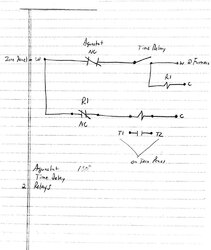

I have a forced air furnace that I am installing a water/air exhanger in . I have one thermostat for the propane burner and will have another to control my circ pump and turn the fan on inside the furnace. I know there is a way to turn off the circ pump when the water temp is too low but I dont' know how to go about it. I want to keep it simple and avoid any fancy controllers. I think I will need an aquastat. Can someone explain to me how this would work and how each component would control the other.

Thanks

Mike

EKo 40 with 500 gallon pressurized storage

Thanks

Mike

EKo 40 with 500 gallon pressurized storage