There's 10x25" rectangular sheet metal coming down from the filter grill (inside the house). If I could figure out how to go straight from that to the 16" flex, things would be much shorter and more direct. But there's really no such fitting (a "boot" I guess), so it'll to be field-fabricated.Still, the return airflow doesn't need to be as spastic as it is now.

HVAC duct issues

- Thread starter RustyShackleford

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

EbS-P

Minister of Fire

They went from big round flex duct to rectangular for mine. I don’t remember if they made it themselves or it was an off the shelf commercial product.There's 10x25" rectangular sheet metal coming down from the filter grill (inside the house). If I could figure out how to go straight from that to the 16" flex, things would be much shorter and more direct. But there's really no such fitting (a "boot" I guess), so it'll to be field-fabricated.

EbS-P

Minister of Fire

There's 10x25" rectangular sheet metal coming down from the filter grill (inside the house). If I could figure out how to go straight from that to the 16" flex, things would be much shorter and more direct. But there's really no such fitting (a "boot" I guess), so it'll to be field-fabricated.

Square to Round Transition Box - Galvanized | HVAC | FAMCO

The FAMCO Square to Round Transition Box connects a square diffuser to a round pipe. Multiple sizes available. Read page for details.

Thanks, but there's no option that does what I need (all the ones that transition to 16" round are at least 16" in both dimensions of the rectangle, it seems).Square to Round Transition Box - Galvanized | HVAC | FAMCO

The FAMCO Square to Round Transition Box connects a square diffuser to a round pipe. Multiple sizes available. Read page for details.www.famcomfg.com

The 10x25 coming down from the grill does a right-angle and becomes horizontal, and there's certainly room to put a 16" starting collar there; but it'd be pointing downwards, so the 16" flex would have a sharp bend to turn horizontally towards the air handler. I wonder about coming out the side of the vertical 10x25" with a 10" starting collar and then a 10-to-16" reducer. There'd be that 10" constriction, but I think that'd be better than a sharp 90-degree in the 16" flex; not sure about that though.

semipro

Minister of Fire

You can get filters that you can install in the registers that may help trap any fiberglass that does break loose in your trunk. I had similar concerns and found some at the big box stores.Oh lord. You nailed it. That's the stuff. I think I have a major problem. My wife sneezes probably at least 30 times a day (not exaggerating). And has had pneumonia several times in the past two years. And she's otherwise a pretty healthy person. Of course, that's clearly a website with an agenda (per its name); I need to look into this more.

I was concerned enough about our ductwork for a variety of reasons that I replaced almost all of it with metal.

DIY ? I'm tempted. My crawlspace is encapsulated, so thinking I wouldn't need to insulate.I was concerned enough about our ductwork for a variety of reasons that I replaced almost all of it with metal.

semipro

Minister of Fire

Yes, all DIY.DIY ? I'm tempted. My crawlspace is encapsulated, so thinking I wouldn't need to insulate.

The distribution box at the AH was the biggest challenge. Sizing and routing the rest of the ductwork for good flow distribution was the next most challenging thing. I was able to assemble standard off-the-shelf metal duct pieces for the most part.

I will warn you that metal ducts transfer noise to the registers more so than flexible or rigid fiberglass. Fortunately, we were going to a much quieter AH so it all worked out.

EbS-P

Minister of Fire

My main return goes 20x30 flitter then down a foot then it goes 20x 20 to 180° turn to get around to pier then they bring in an 8 x 20 then they transitioned to 20 inch round flex duck straight back to the unit. Supply is 15’ of flex then metal.Thanks, but there's no option that does what I need (all the ones that transition to 16" round are at least 16" in both dimensions of the rectangle, it seems).

The 10x25 coming down from the grill does a right-angle and becomes horizontal, and there's certainly room to put a 16" starting collar there; but it'd be pointing downwards, so the 16" flex would have a sharp bend to turn horizontally towards the air handler. I wonder about coming out the side of the vertical 10x25" with a 10" starting collar and then a 10-to-16" reducer. There'd be that 10" constriction, but I think that'd be better than a sharp 90-degree in the 16" flex; not sure about that though.

All runs are 6 inch flex. I would not have had the skills to do this job.

I think a flex duct turn is less restrictive than reducing the 16 to 10 that’s less than half the area.

Hmm, kinda wondering if my return path is really responsible for my 0.5-0.6 iwc of static pressure on the return side. My filter grill is 20x25, comes down into the crawlspace in 10x25 metal, then a right-angle turn, then another right-angle turn, then to about 8ft of 16" flex to the AH. The flex is NOT properly pulled tight though.My main return goes 20x30 flitter then down a foot then it goes 20x 20 to 180° turn to get around to pier then they bring in an 8 x 20 then they transitioned to 20 inch round flex duck straight back to the unit.

But what else could it be ? As I said above, I tried not only removing the filter altogether, but leaving the grill door open !

Maybe I measured it wrong ? JUst drilled a tight hole right before the AH. Didn't use a "static tip" or point it towards the airflow.

EbS-P

Minister of Fire

No one measured mineHmm, kinda wondering if my return path is really responsible for my 0.5-0.6 iwc of static pressure on the return side. My filter grill is 20x25, comes down into the crawlspace in 10x25 metal, then a right-angle turn, then another right-angle turn, then to about 8ft of 16" flex to the AH. The flex is NOT properly pulled tight though.

But what else could it be ? As I said above, I tried not only removing the filter altogether, but leaving the grill door open !

Maybe I measured it wrong ? JUst drilled a tight hole right before the AH. Didn't use a "static tip" or point it towards the airflow.

Does your filter whistle?

How many cfm is it set to run at now?

Keep drilling holes further away and see where the biggest restriction is.

No, filter doesn't whistle. Set for 1000cfm or so. Good idea on drilling more holes !No one measured mine

Does your filter whistle?

How many cfm is it set to run at now?

Keep drilling holes further away and see where the biggest restriction is.

Ok, it's kinda balanced. About 0.25 iwc for the filter itself, 0.15 for the 10x25 rectangular duct with the two right-angles in it, and 0.2 or so for the 8ft of 16" flexduct (which has a right-angle in it and is not properly stretched out).Keep drilling holes further away and see where the biggest restriction is.

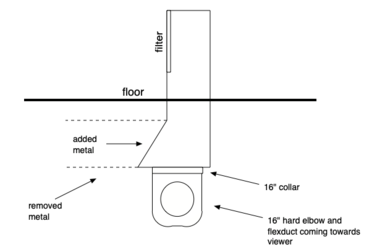

I think I can remove most of the 10x25" rectangular and just put a 16" starting collar at the bottom of where it comes down from the filter, and then a hard 16" elbow, and then a very straight (and properly-stretched and somewhat shorter) run of 16" flex duct over to the airhandler. See image below. Afraid there'd be a fair amount of turbulence there where the 10x25 widens out to something like 18x25 and then narrows into the 16" starting collar.

But I'm wondering if something. more dramatic is in order. Put this in the crawlspace:

... and short flexduct (or maybe even hard) from it to airhandler. But I'm still stuck figuring out how best to go from the 10x25" rectangular duct (coming down vertically from the filter grill in the house) to 16" round. But at least I've reduced the filter pressure drop considerably.

Last edited:

EbS-P

Minister of Fire

Going bigger would reduce the velocity enough that I would not think it would increase static pressure even if there was a bit of turbulence.Ok, it's kinda balanced. About 0.25 iwc for the filter itself, 0.15 for the 10x25 rectangular duct with the two right-angles in it, and 0.2 or so for the 8ft of 16" flexduct (which has a right-angle in it and is not properly stretched out).

I think I can remove most of the 10x25" rectangular and just put a 16" starting collar at the bottom of where it comes down from the filter, and then a hard 16" elbow, and then a very straight (and properly-stretched and somewhat shorter) run of 16" flex duct over to the airhandler. See image below. Afraid there'd be a fair amount of turbulence there where the 10x25 widens out to something like 18x25 and then narrows into the 16" starting collar.

But I'm wondering if something. more dramatic is in order. Put this in the crawlspace:

... and short flexduct (or maybe even hard) from it to airhandler. But I'm still stuck figuring out how best to go from the 10x25" rectangular duct (coming down vertically from the filter grill in the house) to 16" round. But at least I've reduced the filter pressure drop considerably.

View attachment 321081

Just dump the 8x25 into something like 24x 24 (20x20 would work too I guess) coming towards the viewer. Turning vanes are a thing you could add I wouldn’t bother. Then run that as far as you can or want to, then go to flex with the collar.

Looks like it's actually fiarly simple and not too expensve to upgrade to 4" filter. I gather that has a lot of advantages in addition to reducing pressure drop ...

All I can say is that thanks to the advice in this thread, plus a few youtube videos, I have seriously improved my ductwork.

Who knew the flex duct needed to be pulled tight ? Actually, when you first open a new box of the stuff, you and a helper should pull it out to full length and hold it there with 20-30lb of force for a solid minute; this stretches out the helical wire. Then when you install it, make sure you pull it tight; this is a little tricky, because when you go to attach it to the takeoffs, it doesn't want to stay. So I pre-cut a couple of little pieces of mastic tape to hold it in place temporarily; then a zip-tie to hold it good, and then a complete circle of mastic tape to seal it.

And though code wants it suspended every 4ft IIRC, I do it more like every 2ft, and make sure there are no sags.

Also, if it doesn't come straight out the trunk at near a right-angle, I first put a hard adjustable elbow on the takeoff, so the flexduct is straight from there to the floor register; and if the angle to the floor register is awkward, I'll put a hard elbow there too. Yesterday, just adding a hard elbow, after I'd done everything else I mentioned, made a noticeable improvement.

One small BR that was not getting enough air, I noticed the flexduct was about 15ft long. So I cut a new floor register, much closer to the trunk. It's better to get air coming in at the wrong place (near an interior wall, not near a window) than not coming in at all.

For my MBR that was getting way too much air, I used takeoffs with a damper built it. This is a great one, really well-built and 24ga:

www.zoro.com

www.zoro.com

... and this company, if you just put something in your shopping cart and leave it, they will soon come back at you with a 20% discount, and if you sign up for an account, shipping is free at $50, which two of these takeoffs gets you to.

Who knew the flex duct needed to be pulled tight ? Actually, when you first open a new box of the stuff, you and a helper should pull it out to full length and hold it there with 20-30lb of force for a solid minute; this stretches out the helical wire. Then when you install it, make sure you pull it tight; this is a little tricky, because when you go to attach it to the takeoffs, it doesn't want to stay. So I pre-cut a couple of little pieces of mastic tape to hold it in place temporarily; then a zip-tie to hold it good, and then a complete circle of mastic tape to seal it.

And though code wants it suspended every 4ft IIRC, I do it more like every 2ft, and make sure there are no sags.

Also, if it doesn't come straight out the trunk at near a right-angle, I first put a hard adjustable elbow on the takeoff, so the flexduct is straight from there to the floor register; and if the angle to the floor register is awkward, I'll put a hard elbow there too. Yesterday, just adding a hard elbow, after I'd done everything else I mentioned, made a noticeable improvement.

One small BR that was not getting enough air, I noticed the flexduct was about 15ft long. So I cut a new floor register, much closer to the trunk. It's better to get air coming in at the wrong place (near an interior wall, not near a window) than not coming in at all.

For my MBR that was getting way too much air, I used takeoffs with a damper built it. This is a great one, really well-built and 24ga:

Greenseam Collar W/Damper, 6 in Duct Dia, Galvanized Steel, 24 GA, 8 in W x GR6POCR6GA24D | Zoro

Order Greenseam Collar W/Damper, 6 in Duct Dia, Galvanized Steel, 24 GA, 8 in W x, GR6POCR6GA24D at Zoro.com. Great prices & free shipping on orders over $50 when you sign in or sign up for an account.

... and this company, if you just put something in your shopping cart and leave it, they will soon come back at you with a 20% discount, and if you sign up for an account, shipping is free at $50, which two of these takeoffs gets you to.

gthomas785

Minister of Fire

Yeah. Flex duct is installed wrong about 90% of the time even by professionals. Good job reading the directions.

UK, NY, Canada, Kansas City? I think your passport is about to get revoked.We're having issues with our 2nd story not blowing cool air when the A/C is on. I went into the attic and noticed that the ducting isn't insulated at all. We live in Kansas City and the temp is mid 90s and heat index into the 100s in the summer. Do I need to have a professional come out and insulate all the ducting in the image gallery attached? Also does cleaning out the air ducts actually do anything? We just moved into this house a while ago and the A/C is only 4 years old. Thanks for any guidance!

Similar threads

- Replies

- 9

- Views

- 4K

- Replies

- 13

- Views

- 2K

- Replies

- 41

- Views

- 8K

- Replies

- 6

- Views

- 2K