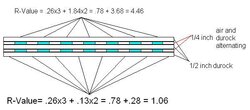

I am realizing my mental limitations. I am trying to figure out what and how to use as floor protection and wall protection. I was looking at trying to reduce how far my stove will need to set out from a combustable wall. The manual indicates my model of stove comes with a rear shield and I may place the stove 8 inches from combustables. However the stove pipe must be 16 inches from combustables. If I have measured right the stove pipe is 4 inches from the back of the stove. It looks like I must place my stove 12 inches from the combustable wall to satisfy the pipe clearance. I am hoping some 30 users will step in here and help me understand this a little better' Please advise what is the most practical and visually appealing way to protect my wall. Then it also says I need a R value of 1.5 for the floor protection. I initially want to do a raised tile hearth but because of the shear size of the minimally allowed hearth (39x52.5) I think I will have to do something more at floor level. I have been blow away by all the rocket science and need help. Thanks for the patience.

I am really feeling dumb. Trying to get hearth for Englander 30

- Thread starter Spoon

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.