Hello,

I needed to clean my flue & boiler tubes, and as I was mindlessly brushing the tubes, I wondered if there were any things that I could do to improve my boilers efficiency, when I hook up my tank, later on this week.

SO

Assuming well seasoned & dry wood :

1 - Wood size - what would my optimum wood size be? would real small be better? 2x4 size?

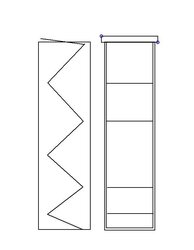

2 - Tubes - my boiler tubes go straight up & out the flue & no damper (just barometric damper)

Could I space a thick baffle plate (divide chamber) over the tubes to slow down flue gas or recirc somehow?

(I noticed that the tubes at the 4 corners clog with ash)

3 - Pressurize it - remove barometric damper and add 2nd combustion fan for more air.

Any Suggestions?

I needed to clean my flue & boiler tubes, and as I was mindlessly brushing the tubes, I wondered if there were any things that I could do to improve my boilers efficiency, when I hook up my tank, later on this week.

SO

Assuming well seasoned & dry wood :

1 - Wood size - what would my optimum wood size be? would real small be better? 2x4 size?

2 - Tubes - my boiler tubes go straight up & out the flue & no damper (just barometric damper)

Could I space a thick baffle plate (divide chamber) over the tubes to slow down flue gas or recirc somehow?

(I noticed that the tubes at the 4 corners clog with ash)

3 - Pressurize it - remove barometric damper and add 2nd combustion fan for more air.

Any Suggestions?