- Mar 25, 2012

- 36

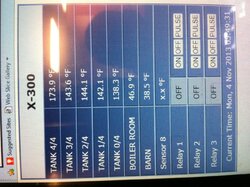

When I installed my Tarm, I opted for the cheaper Termovar, without temp readings. What are you guys, who are similarly thrifty, doing for temp monitoring, if you bother.

Isn't this just lovely weather? I was okay night before last, but last night, I got just a little behind; had to burn an extra half load of wood.

Isn't this just lovely weather? I was okay night before last, but last night, I got just a little behind; had to burn an extra half load of wood.