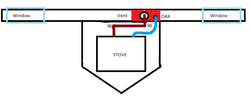

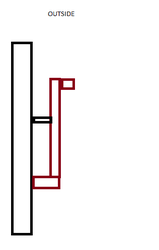

I have attached a very horrible picture of my current setup, drawn in wonderful MS Paint. I also attached a picture (also in horrible paint) of what the outisde will be with the rise. My previous installation had a cleanout T installed right behind the stove adapter (acting as the first 90), then a 2nd 90 to go out of the wall into a straight exhaust. Now with the Englander, they are requiring I have a 3 foot rise in the pipe. So my question is, would you:

A. Keep the cleanout T on the inside, then a 90 out, then a cleanout T on the outside leading up to a 3ft rise. This would be 4 90's total (including the cleanouts).

B. Use two 90's on the inside and put a cleanout T on just the outside.

C. Keep the cleanout T on the inside, and just use 90's on the outside. Purchase leaf blower. lol

I know the location of the install is awkward but the hole in the wall was from the previous homeowner's pellet stove, which I can only surmise is off center because of stud locations.

Option D would be to completely off center the stove between the two windows and vent directly out. This is probably a no go simply because it will look awkward as heck.

Thanks all!

A. Keep the cleanout T on the inside, then a 90 out, then a cleanout T on the outside leading up to a 3ft rise. This would be 4 90's total (including the cleanouts).

B. Use two 90's on the inside and put a cleanout T on just the outside.

C. Keep the cleanout T on the inside, and just use 90's on the outside. Purchase leaf blower. lol

I know the location of the install is awkward but the hole in the wall was from the previous homeowner's pellet stove, which I can only surmise is off center because of stud locations.

Option D would be to completely off center the stove between the two windows and vent directly out. This is probably a no go simply because it will look awkward as heck.

Thanks all!