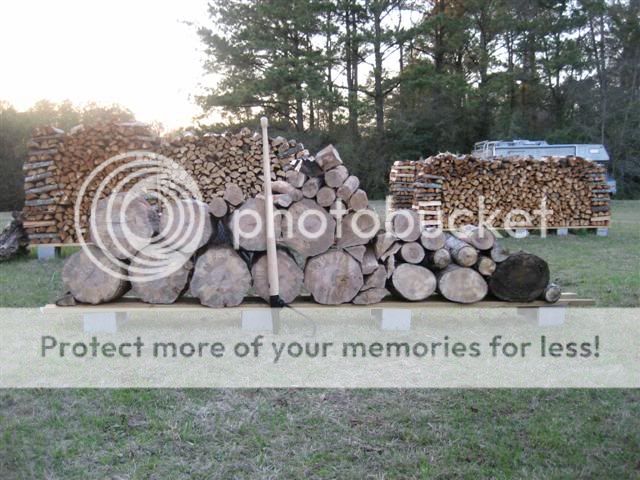

I got to thinking about my wood stacks and the "specs" of the stack structure, location, etc.,. The structure design definitely isn't my design or idea and rdust and his stacks was definitely a deciding factor on me doing it this way...of course his is a little more intensive than mine.

I'm using 8x8x16 blocks and pt 2"x4"x12' (check the cull racks at the lumber yard). I go to a little trouble to get the 2by/block foundations fairly level from end to end...I think the more important leveling is from side to side (16" narrow dimension).

I begin by starting a crib (maybe 1.5'-2.0' tall) on each end for end support and then start stacking in the center of the stack so that the stack "falls in" against itself thus taking some of the pressure off of the end cribs. You can see by the picture that the stack gets fairly high before it touched the cribs at the end of the stacks. This idea of stacking in the center came from somewhere here on hearth.com or elsewhere, it was definitely not an original idea by me, but it certainly appears to work in helping stack stability!

.

Anyhow, the stacks are 12' long and designed for a 4' height. The first stack (left rear stack with the mix of green and seasoned wood in it) is a bit over this, more like 5' tall but it will be lowered a bit for stability reasons. At 12' long and 4' tall each stack will hold a half of cord of green wood.

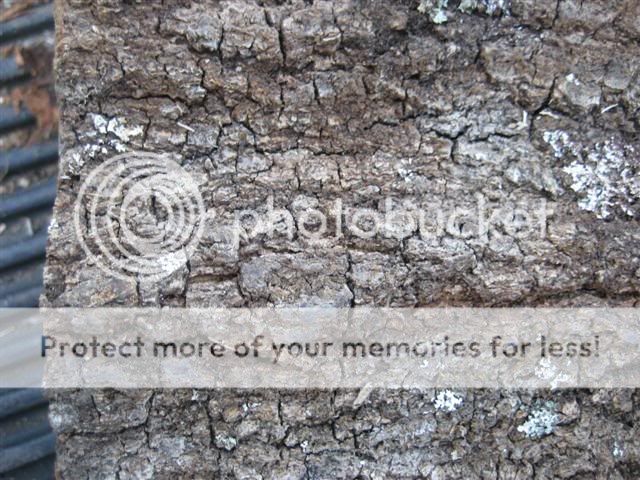

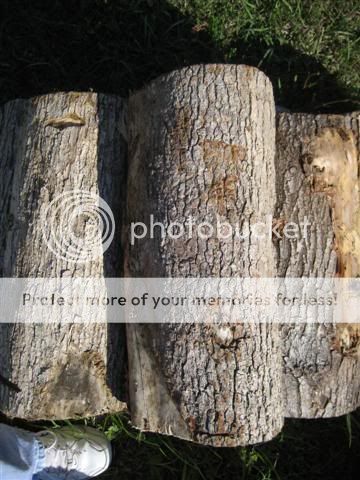

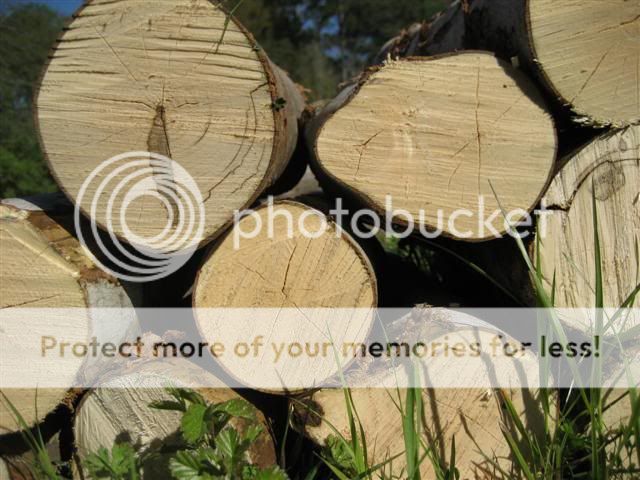

The wood I'm stacking is water oak and I'm figuring a green weight of 4886 pounds. This figures to be close to 490# loaded on each block. I was a bit concerned about the blocks being able to hold this much weight laying on their sides as they are but they appear to be handling it well...and as evidenced by other folks use they seem to work ok in this orientation. As time goes by the wood's weight will decrease as it dries...using a weight of 3550# for red oak dried down to 20% MC this would reduce the loads on each block to around 355 pounds. Here is an interesting wood weight / moisture content webpage that you might want to check out...

Wood Species - Weight at various Moisture Contents

Stacks are oriented north/south with the prevailing wind coming from the southwest. Each stack is "set back" north by about a foot from it's eastern neighboring stack...I figured this might give each easterly stack just a little extra "sail" to catch any wind passing by. Stacks are roughly 68" apart (room for the mower) and the ends of the stacks that are inline with each other are about that far apart, also. There is at least 6" of ventilation under the stacks (some blocks were dug into the ground to level things up). During the summer these stacks will be exposed to sun basically from ~7am till ~6pm...wintertime from about 9am till 4pm.

We had some 40mph winds the other day and the stacks held fine. I'm not sure how they'll do as they dry...or when the next hurricane comes through. :bug: I'm considering some cross-bracing where one end of a pole or 2by is placed against a block of one stack with the other end against the neighboring stack...probably four poles bracing each stack (2 to the side). That might be aggravating in regards to mowing the grass but restacking a half cord of wood might be rather aggravating, too!

We'll see how it goes.

I've also got some old tin I'm considering putting on top of the stacks. I figure I can set a few splits on top of the stacks to elevate the tin above the stacks a few inches. That will probably be a summer project.

Anyhow, for whatever reason...there's some details on my wood stacks.

Ed

.

.

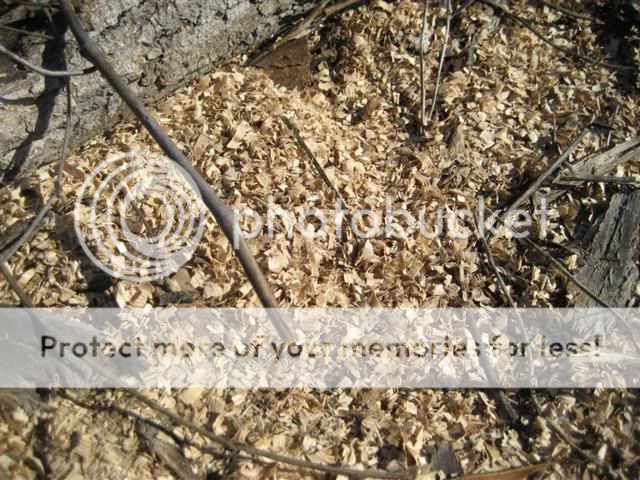

I might have to save up my rounds and rent a splitter later, we'll see.

I might have to save up my rounds and rent a splitter later, we'll see.

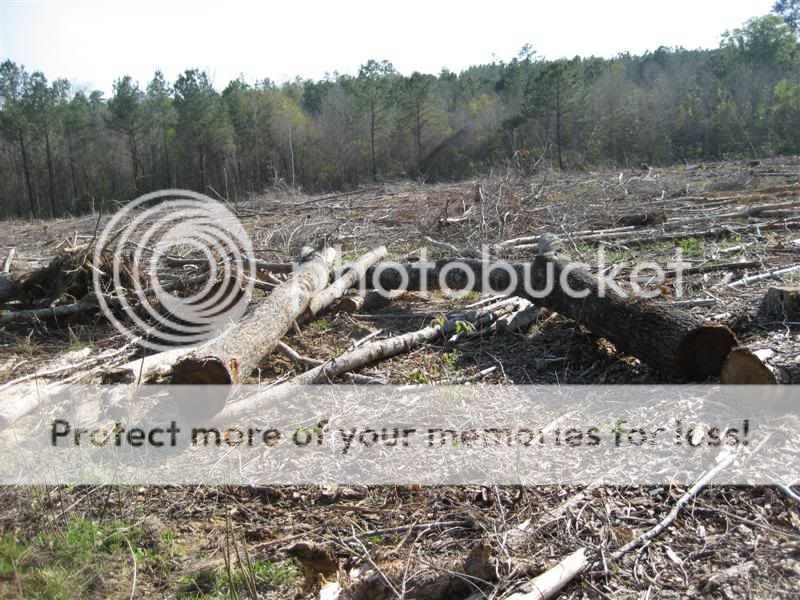

Riding in north Georgia made me wish I could buy five acres of that timberland and somehow transport it down here. Ah well, we all burn what we got, eh?

Riding in north Georgia made me wish I could buy five acres of that timberland and somehow transport it down here. Ah well, we all burn what we got, eh?