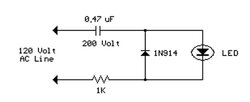

This one is a convenience, and a way to know that power is going to the circ that you wonder whether or not it is "on." How about an LED light on the circ electrical box, or a control panel, that lights up when power is "on" to the circ? Here's a circuit I picked up off the Web, wired it up today, works great. I drilled a small hole in the circ electrical hookup box to insert the LED. The rest of the components are very small and easily fit in the box. Wire it to the same wire nuts that connect the circ with power. I soldered the parts together and then wrapped everything with plastic electrical tape to prevent any inadvertent electrical short. Total cost for two of these was less then $5. The specified diode is not critical, just about any diode rectifier rated at 150 or more volts is my guess. Current draw is minimal. Radio Shack may have all the parts, or an electronic surplus store also would be good. The resistor is 1/2 watt.

You can find the circuit at AC LED Circuit

April 06, 2009: Safety is really important, and if this 120 volt circuit for LED's is not adequately protected, it should not be used. See discussion on the following posts.

You can find the circuit at AC LED Circuit

!

!