Hi,

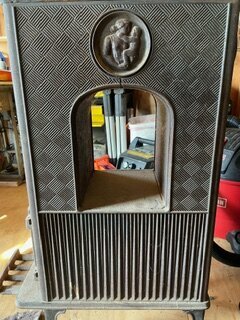

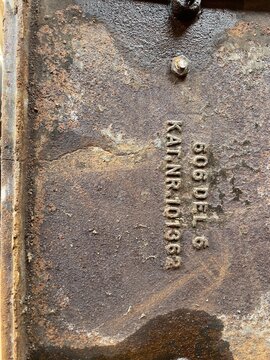

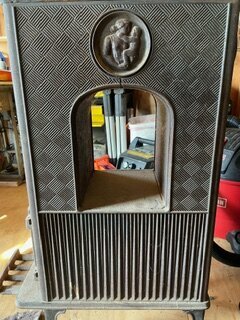

This is my latest project'.....a Jotul 606 (circa the 70s I think). I'd like to restore it for a family member as it has sat in the corner of a barn in Maine for about 25+ years (it was originally from home outside Boston before that). I think it has a beautiful design and is probably best suited for light parlor room type duty. It seems in good condition overall and is also complete. The archway design will make an interesting tear down and rebuild (i.e. it has more parts than a

simple "box" stove). Any insight is appreciated. Pics are attached. My two initial questions are below. Many thanks!!

This is my latest project'.....a Jotul 606 (circa the 70s I think). I'd like to restore it for a family member as it has sat in the corner of a barn in Maine for about 25+ years (it was originally from home outside Boston before that). I think it has a beautiful design and is probably best suited for light parlor room type duty. It seems in good condition overall and is also complete. The archway design will make an interesting tear down and rebuild (i.e. it has more parts than a

simple "box" stove). Any insight is appreciated. Pics are attached. My two initial questions are below. Many thanks!!

- Any idea where I can get new burn plates state side? I see some for sale in the UK but not seeing a lot here in the U.S.

- How should I deal with what looks like a crack in the side plate just below the Mother and child motif (2nd pic)? I am not sure if this is really a crack or just casting marks since both sides have it and every 606 picture that I see online has them too.