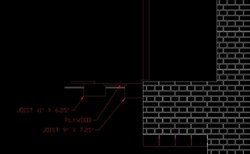

I'm planning on removing some wood flooring and then blocking and laying two layers of 3/4 ply flush with the top of the joist. I'm thinking of laying in 1/2" of Micore, then 1/2" of Hardy Backer (maybe two layers of HB) Then tilling it. I'll be filling in the original hearth with brick and mortar and continuing my tile over the brick to the back of the fireplace. I'll not be able to make it flush with the finish floor doing it this way, but it'll be close, I can live with that. My question is what do you think of my plan?

I know it's and ember protection only stove, but I'd rather over build it just incase I put something else in down the road. One thing I noticed in the manual was it said to use a non combustible hearth pad for ember protection and radiant heat. The radiant heat part concerned me, how hot does the floor get in front of the stove? With my install the stove itself will be on the original hearth from there forward it'll be wood under my tile extension.

I know it's and ember protection only stove, but I'd rather over build it just incase I put something else in down the road. One thing I noticed in the manual was it said to use a non combustible hearth pad for ember protection and radiant heat. The radiant heat part concerned me, how hot does the floor get in front of the stove? With my install the stove itself will be on the original hearth from there forward it'll be wood under my tile extension.