Key Damper Theory

- Thread starter 30WCF

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

EbS-P

Minister of Fire

My two cents after running a damper on 23’ of insulated liner.

It adds a whole new variable to stove operation. With a set it am forget it VC C3 I really think it only needs two positions. Start up and burn. Maybe adding a warm weather setting too. (If you do that then you probably need the frigid windy setting too but that’s complicating things).

Dampers are not oh no it’s to hot buttons. They are draft regulators. I have mine almost figured out. But with a stove with unregulated secondary air I must force my self to set the damper and not touch it. Otherwise I’m playing with air and damper settings.

Ideally we all have manometers and can measure WC and flue temps. Most of us don’t. So we just guess at what we need. And we can do a decent job.

I don’t see the functional difference between OAK restriction and a flue damper. With one exception the draft number could still be really high with restricted OAK intake resulting in increased air from leaks. (You keep sucking on the straw but flow is limited vs biting the top of the straw and sucking. ).

Damper makes more sense to me. But for emergency shutdowns air intake control is a good idea. Better plan is to have draf in spec so that is not needed. But on a stove with no user control it probably needs it.

It adds a whole new variable to stove operation. With a set it am forget it VC C3 I really think it only needs two positions. Start up and burn. Maybe adding a warm weather setting too. (If you do that then you probably need the frigid windy setting too but that’s complicating things).

Dampers are not oh no it’s to hot buttons. They are draft regulators. I have mine almost figured out. But with a stove with unregulated secondary air I must force my self to set the damper and not touch it. Otherwise I’m playing with air and damper settings.

Ideally we all have manometers and can measure WC and flue temps. Most of us don’t. So we just guess at what we need. And we can do a decent job.

I don’t see the functional difference between OAK restriction and a flue damper. With one exception the draft number could still be really high with restricted OAK intake resulting in increased air from leaks. (You keep sucking on the straw but flow is limited vs biting the top of the straw and sucking. ).

Damper makes more sense to me. But for emergency shutdowns air intake control is a good idea. Better plan is to have draf in spec so that is not needed. But on a stove with no user control it probably needs it.

If you are talking the shop stove that Highbeam has, he runs it hard, but carefully with a lot of air blowing over it. This is not a stove that is running every day at those temps, 24/7. So 750º yes, 850º no, not if you want the stove to have a good long life.Some of the longer tenured members here with the NC30 have told me they hit 850 stt every load and could do a full reload every 4-5 hours if they are really cranking it. I wonder what flue temps would be with that stt...? 1000? 1100?

Likewise. I set up our stove with a flue damper this year for testing. It has been quite unnecessary with our normal 30-40º weather, but with temps in the teens creating a stronger draft and a stove full of harwood, it does help tame the beast and keep the flue temps reasonable. I am using it like an on-off switch.My two cents after running a damper on 23’ of insulated liner.

It adds a whole new variable to stove operation. With a set it am forget it VC C3 I really think it only needs two positions. Start up and burn. Maybe adding a warm weather setting too. (If you do that then you probably need the frigid windy setting too but that’s complicating things).

This morning I got up early to set out a warm hummingbird feeder before they woke up. The house was dark, I just had the kitchen light on when I went to reload the stove on hot coals. The living room was dark except for the glow of coals. I didn't notice until almost done that there was smoke spilling out of the stove. My bad, the damper was still closed. At 17º out I was not going to open windows. It took a couple hours for the smoky smell to disapate. Hope I don't repeat that again.

I think it may have been MadMark who made that comment when I first got mine. He and Highbeam were extremely helpful in shortening my learning curve. I just prefer to keep stt under 700.If you are talking the shop stove that Highbeam has, he runs it hard, but carefully with a lot of air blowing over it. This is not a stove that is running every day at those temps, 24/7. So 750º yes, 850º no, not if you want the stove to have a good long life.

I do have the damper, and probably need to

play with setting it earlier when I load a little heavy. I generally know which loads are gonna take off, due to the coal bed or load size. The one in the beginning of the thread was a fluke with the logs bracing themselves up.

I don’t think it acts the same as the flue damper. I’ve cooled this stove several times by placing my hand, or foil over the intake. Not sealing it, but limiting the air some, and it drops immediately. If it were so leaky that this didn’t work, I’m sure I would have other problems already presenting themselves. Its not a problem stove, just some days you mess up.

This may be good insurance if I want to try to start loading heavier, and utilizing the flue damper to try to keep it cool for longer burns. This cools it down. A fully closed damper doesn’t. This would act much like the air control on the old smoke dragons if it was used like that. I don’t intend to do that, but if I add more wood than I have been, I need to be able to slow something down.

play with setting it earlier when I load a little heavy. I generally know which loads are gonna take off, due to the coal bed or load size. The one in the beginning of the thread was a fluke with the logs bracing themselves up.

I don’t think it acts the same as the flue damper. I’ve cooled this stove several times by placing my hand, or foil over the intake. Not sealing it, but limiting the air some, and it drops immediately. If it were so leaky that this didn’t work, I’m sure I would have other problems already presenting themselves. Its not a problem stove, just some days you mess up.

This may be good insurance if I want to try to start loading heavier, and utilizing the flue damper to try to keep it cool for longer burns. This cools it down. A fully closed damper doesn’t. This would act much like the air control on the old smoke dragons if it was used like that. I don’t intend to do that, but if I add more wood than I have been, I need to be able to slow something down.

I will pick through what I have and see if I can find some that match up. It’s tricky with this small of a box. Most of my seasoned wood was split for a larger stove that I used to have. Some of the medium pieces just don’t stack well in this box.Your splits are small, they will take off and be less controllable. Put 2 or 3 large splits in there that fill more of the box and see how she runs.

Ok. I’ve had some good luck with getting 6-7 hrs out of a BIG log a couple times. I need to load it on some good coals to get it going, but then it will run most of the night. Fie bricks are clean and white, window is a little sooty, but wipes off clean with a dry paper towel , even while hot, doing a hot reload. Just hit it with a dry towed and crystal clear. So, I’m burning clean enough.

If I’m going to try the flue damper to see if I can get an hour or two longer, where would you suggest I start?

I’m thinking full send. The spring controlled intake damper will still be closed at this point, so technically, by design, the air is still shut down as far as it will go. Since the flue damper isn’t 100% restriction, and the stove is already breathing on only what air can get into the primary and secondary through these two tiny holes……

There is a divider behind there. One side is primary, the other side is secondary air. Thats all it’s getting. When the stove is cold, the chain lifts the restrictor plate and allows more air to travel underneath, but under most circumstances, that plate is always closed except on a cold start.

That said, it can still get plenty hot as show earlier. It likes to run at 700STT.

Back to the Q?

Big log, hot coals, air is closed down, burns clean for 6-7 hrs and can still relight off coals easily. To get another hour or two, move the flue damper to 50%, 75% or 100% closed? Don’t mess with the aftermarket intake vent.

Or

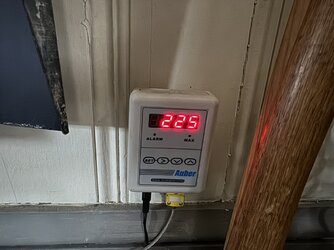

Close the intake enough to see the the Auber drop a couple degrees and settle, and let it go through the nite.

I know it’s trial and error, but just wanted to take a poll.

If I’m going to try the flue damper to see if I can get an hour or two longer, where would you suggest I start?

I’m thinking full send. The spring controlled intake damper will still be closed at this point, so technically, by design, the air is still shut down as far as it will go. Since the flue damper isn’t 100% restriction, and the stove is already breathing on only what air can get into the primary and secondary through these two tiny holes……

There is a divider behind there. One side is primary, the other side is secondary air. Thats all it’s getting. When the stove is cold, the chain lifts the restrictor plate and allows more air to travel underneath, but under most circumstances, that plate is always closed except on a cold start.

That said, it can still get plenty hot as show earlier. It likes to run at 700STT.

Back to the Q?

Big log, hot coals, air is closed down, burns clean for 6-7 hrs and can still relight off coals easily. To get another hour or two, move the flue damper to 50%, 75% or 100% closed? Don’t mess with the aftermarket intake vent.

Or

Close the intake enough to see the the Auber drop a couple degrees and settle, and let it go through the nite.

I know it’s trial and error, but just wanted to take a poll.

EbS-P

Minister of Fire

You’re playing with fire

At this point longer means cooler flue gas temps. What temps (flue and stove top) does the spring open the air back up? Probably doesn’t matter.

Start damper at 45 degrees. And see what that does. Reall if you want long burns leave a full belly of ashes get a really good coal bed load up and turn it down ASAP.

Really if you are wanting to ride the line you will be needing several adjustments of the damper as the burn progresses. IMO that defeats the the load and close he door advantage of the Aspen C3.

At this point longer means cooler flue gas temps. What temps (flue and stove top) does the spring open the air back up? Probably doesn’t matter.

Start damper at 45 degrees. And see what that does. Reall if you want long burns leave a full belly of ashes get a really good coal bed load up and turn it down ASAP.

Really if you are wanting to ride the line you will be needing several adjustments of the damper as the burn progresses. IMO that defeats the the load and close he door advantage of the Aspen C3.

Todd

Minister of Fire

I wouldn’t go down any rabbit hole just yet til you get a little more familiar with the stove. Continue trying different loading technique’s on different sized coal beds.

In the end I’m trying to see if I can make it do something it wasn't designed to do.

It’s a perfectly capable stove, with 4-6 hrs of heat. It can relight way past that depending on what coal bed I’ve allowed to accumulate or burned off.

Right now I’m using pine to burn off the hickory coals from this mornings reload. It’s adequate to be left alone as I usually go to bed a little late, and just wake up at 4:00am regardless. I defiantly mint mind messing with it throughout the day. Just trying to stretch it a tad.

Those big logs on hot coals ran flue temps up in the mid 400s pretty steady while I was watching it.

It’s a perfectly capable stove, with 4-6 hrs of heat. It can relight way past that depending on what coal bed I’ve allowed to accumulate or burned off.

Right now I’m using pine to burn off the hickory coals from this mornings reload. It’s adequate to be left alone as I usually go to bed a little late, and just wake up at 4:00am regardless. I defiantly mint mind messing with it throughout the day. Just trying to stretch it a tad.

Those big logs on hot coals ran flue temps up in the mid 400s pretty steady while I was watching it.

You’re playing with fire

At this point longer means cooler flue gas temps. What temps (flue and stove top) does the spring

the air back up? Probably doesn’t matter.

The probe for the spring is visible from the flue collar, sitting just above the baffle and super wool. I imagine flue temps are more accurate, but both are usually within 20-30 degrees by the time it’s cool enough to open.

Probably on the 250 range to start opening, and sub 200 before it opens fully.

EbS-P

Minister of Fire

So something then I would consider startup air and not helpful to regulate a burn that might might get choked down to much with a damper.The probe for the spring is visible from the flue collar, sitting just above the baffle and super wool. I imagine flue temps are more accurate, but both are usually within 20-30 degrees by the time it’s cool enough to open.

Probably on the 250 range to start opening, and sub 200 before it opens fully.

My experience is that if you want to ride that line you need a load that wants to burn well but your control is what is limiting the air to the burn. I find big logs more difficult t do that with than well loaded load of splits. A small adjustment will yield good results quickly but a big log I just keep chasing the perfect setting. But I can really choke everything down to the point of sub 500 flue temps.

Yup. It works good to keep a properly loaded stove in check from start up, and throughout the main part of the burn. And as long as you are putting in a moderate load of nice dry wood on top of coals, it has sufficient air to burn that fairly cleanly. You could do this around the clock, non-stop and just by adjusting the load or split size to regulate if you want to to run a shoulder load at 350, or a single digits temp load at 750. And when you let it die, it ends in a pile of fluffy ashes just as designed.So something then I would consider startup air and not helpful to regulate a burn that might might get choked down to much with a damper.

Each time there has been a hot fire that I wanted to turn down, there is a obvious culprit that I have always been able to remedy by knocking the logs around to settle them and choking the stove intake for a few seconds in a couple instances.

The line I’m thinking about trying to walk is, can I stuff a big log in there, or load it fuller and manipulate the intake

House started to get cool so I tossed in another split. At that time, the flue was 200 and maybe a 1/16” or 1/32” of lift on the intake damper.

You can just see a dark line at the bottom compared to the previous picture.

If I was keeping it hot, I would have reloaded already, and it would have lit off just fine with full size splits, or if left alone, those coals would have turned to dust.

You can just see a dark line at the bottom compared to the previous picture.

If I was keeping it hot, I would have reloaded already, and it would have lit off just fine with full size splits, or if left alone, those coals would have turned to dust.

T-Rav

New Member

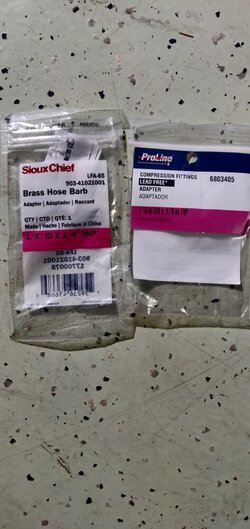

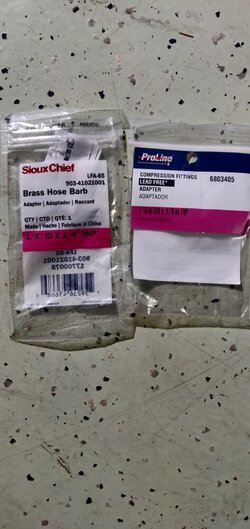

Mark II install update...

So I finally took delivery on Thursday and installed today, gauge is simple design and easy to read from 10 feet away, super easy install, just bought some 1/4" OD copper tubing from Thailand, a Chinese compression fitting and hose barb, and I'm seeing immediate results of my airflow adjustments! Thanks guys for the help!

So I finally took delivery on Thursday and installed today, gauge is simple design and easy to read from 10 feet away, super easy install, just bought some 1/4" OD copper tubing from Thailand, a Chinese compression fitting and hose barb, and I'm seeing immediate results of my airflow adjustments! Thanks guys for the help!

Grandma never had it so good.I'm seeing immediate results of my airflow adjustments! Thanks guys for the help!

Highbeam

Minister of Fire

I don’t think it’s me. My gauge doesn’t even go to 850. Plus I can do full reloads every three hours and never overtemp the flue or the stove. I did burn back to back loads for like 5 loads one day and documented it. Noncats can chew some fuel!If you are talking the shop stove that Highbeam has, he runs it hard, but carefully with a lot of air blowing over it. This is not a stove that is running every day at those temps, 24/7. So 750º yes, 850º no, not if you want the stove to have a good long life.

Last edited:

T-Rav

New Member

She's gonna really love the remodeled smoke baffle I build this summer!Grandma never had it so good.

Similar threads

- Replies

- 45

- Views

- 3K

- Replies

- 23

- Views

- 2K

- Replies

- 68

- Views

- 2K

- Replies

- 11

- Views

- 1K