On your Froling do you have (1) fan, (1) Lambda sensor, (1) smoke temperature sensor and individual stepper/servo motors for both the primary and secondary drafts?

Thanks!

Yes, sorry missed this question.

On your Froling do you have (1) fan, (1) Lambda sensor, (1) smoke temperature sensor and individual stepper/servo motors for both the primary and secondary drafts?

Thanks!

Thanks for that. Although we have the same boiler it is hard for me and my limited experience to compare since our set up is pretty different. I've only made changes two settings. My slumber temp is 90c ( i think 85 or 87 was the default) and there was a timer setting that Tarm walked me though changing in the service menu. I was getting some erroneous "boiler has air leak" message related to the residual oxygen readings. I was burning some real gnarly pieces of wood at the beginning of the season and as a safety, the boiler was interpreting the high residual oxygen content settings as a leak, or leaving a door open. Once Tarm walked me through the change I never got the message again.

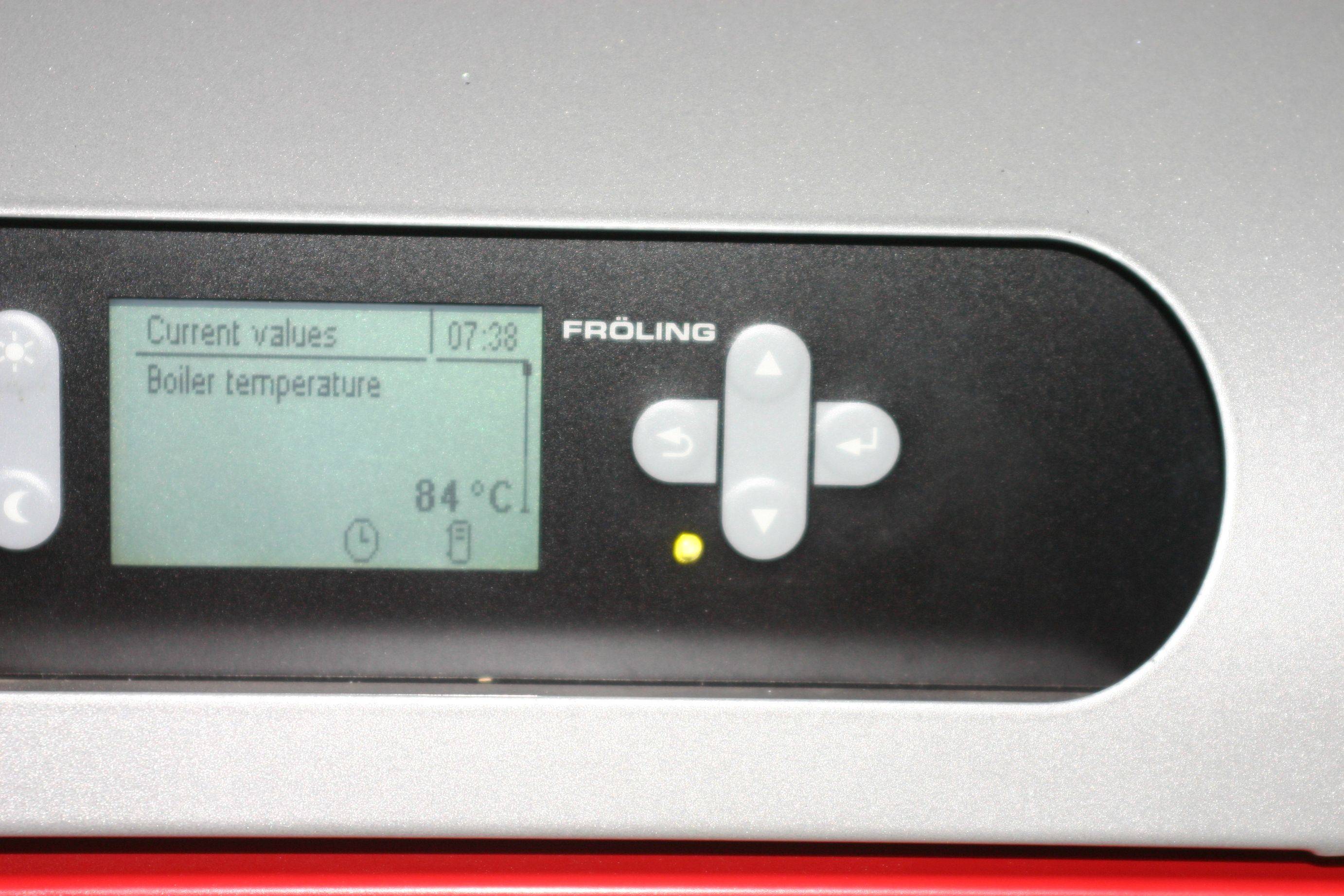

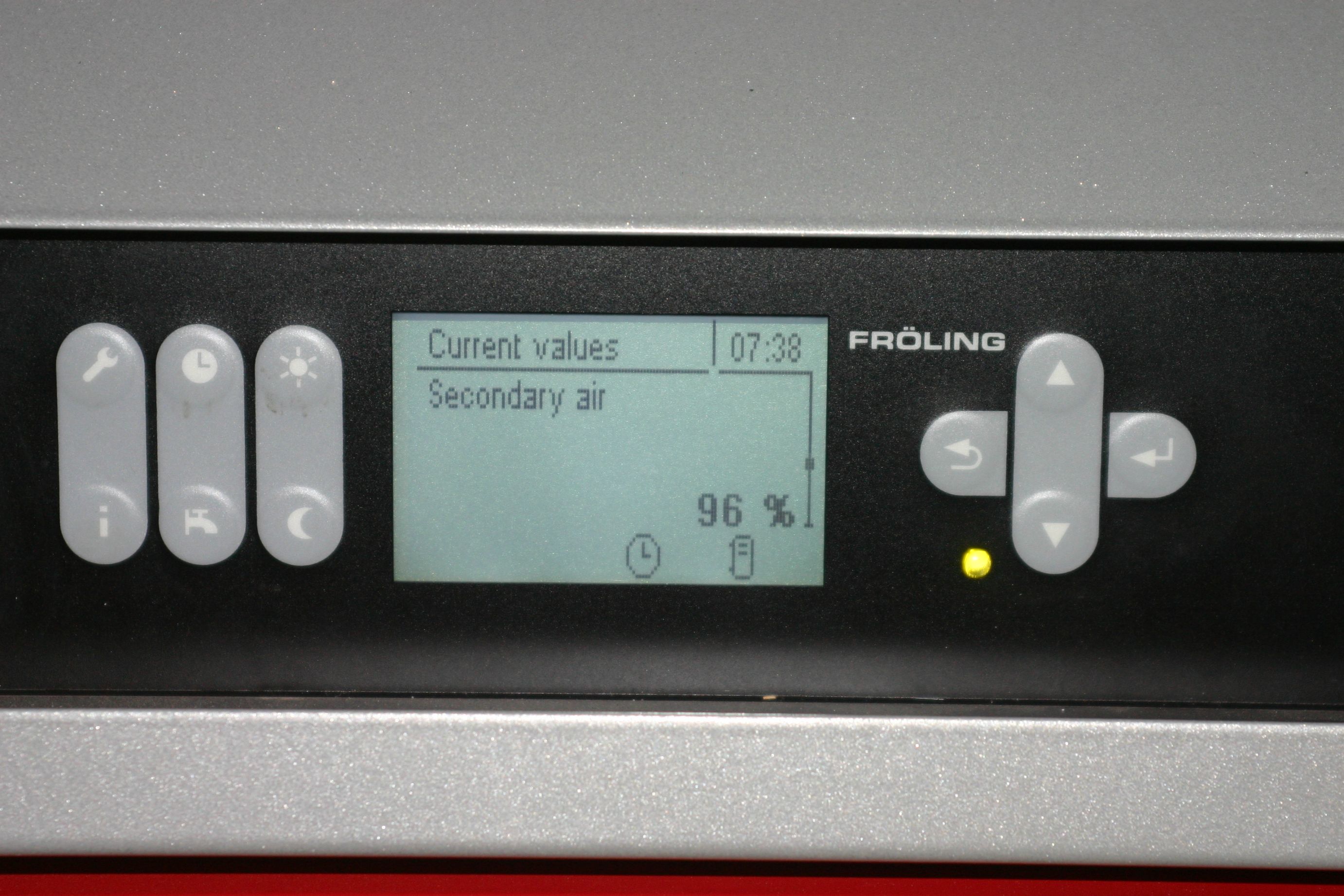

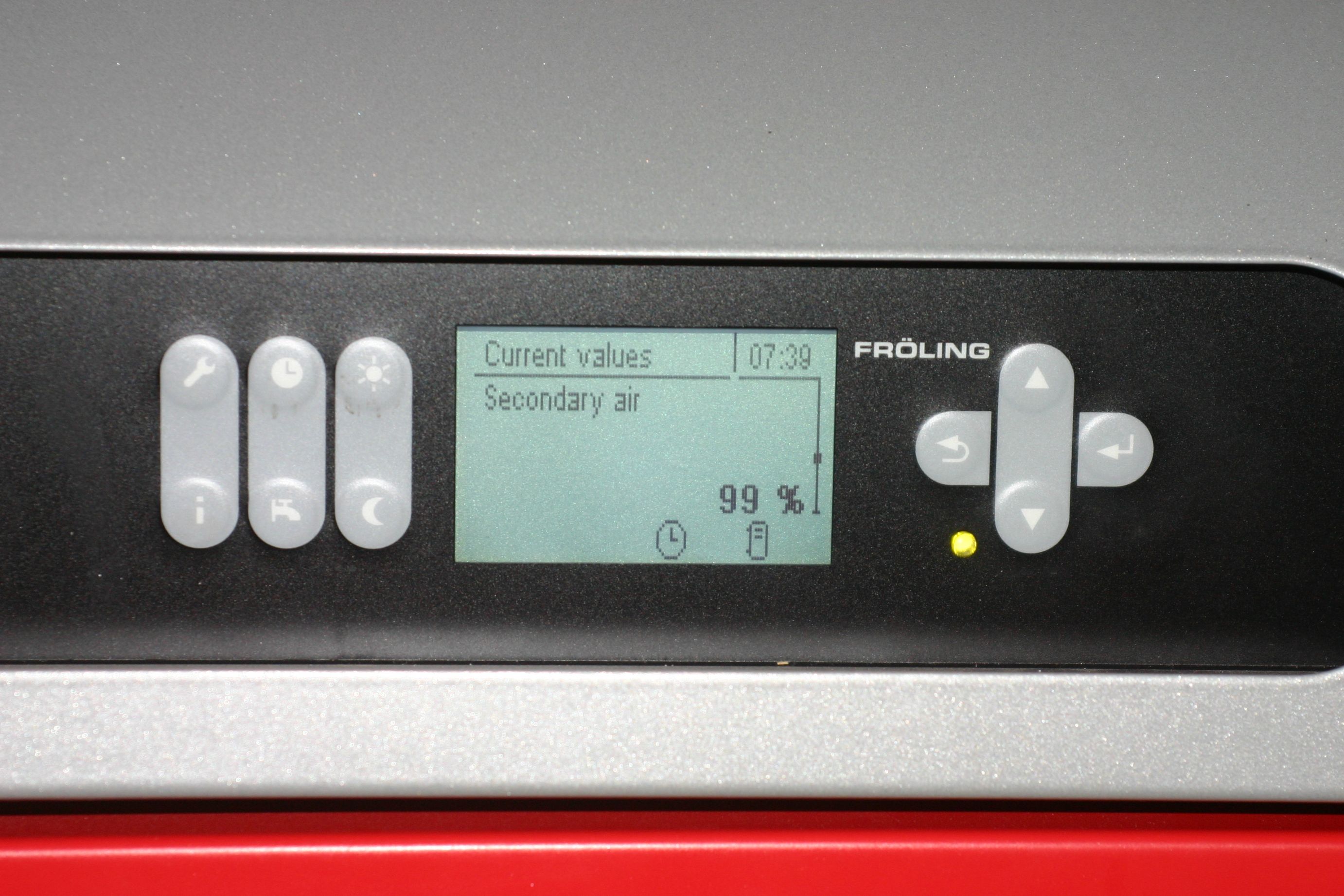

With 220 c flu gas temp I hit 64% on the secondary last night. Our TV room is in the basement, and when I really hear it rumbling I go out for a look. My wife thinks it's dorky as anything, but like I said, I'm a gadget guy and just generally curious about these kind of things.

Enjoying this thread.... A non-lambda guy learning a lot. Thx

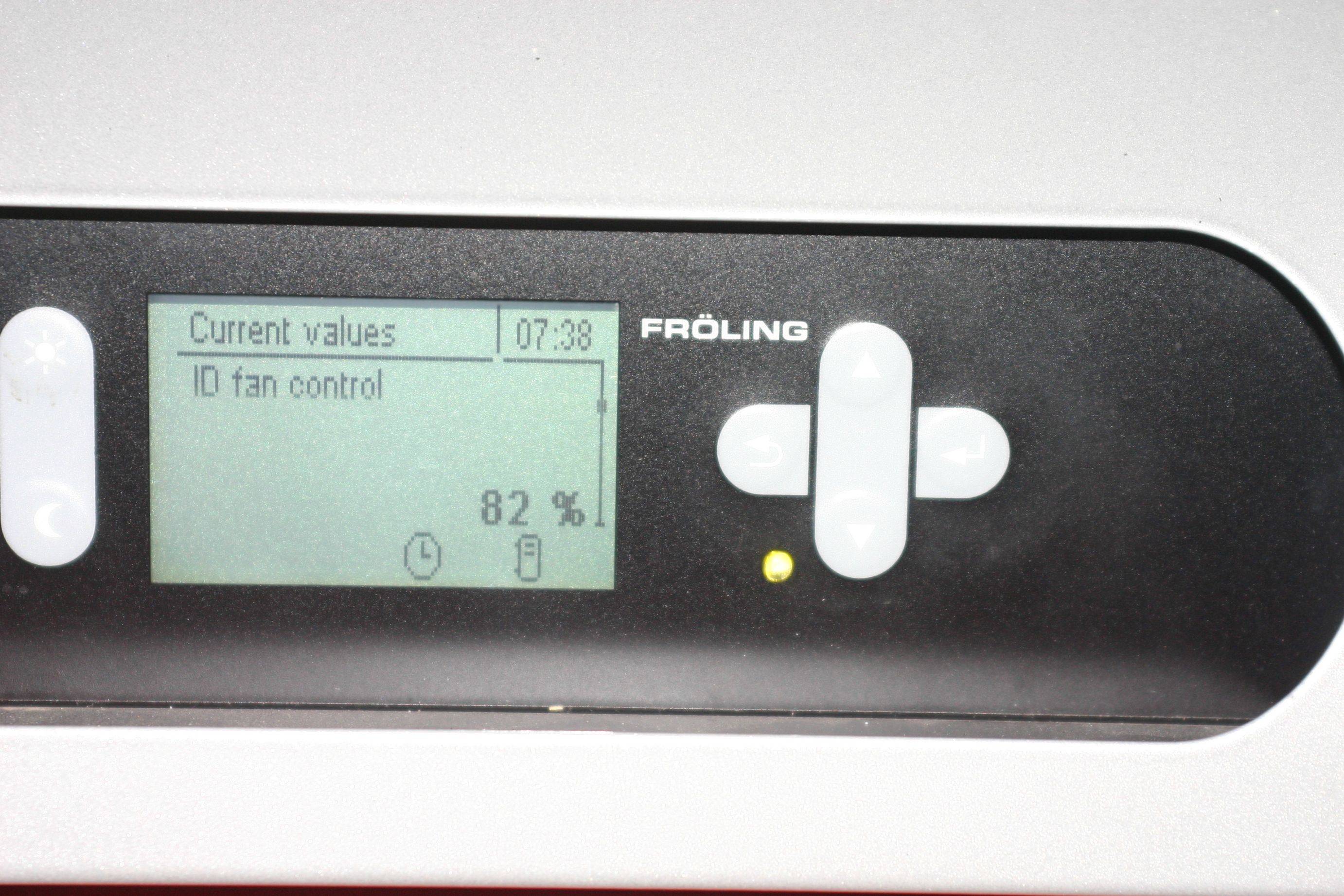

Hiker & Dan, I am curious, at startup what are the p/s damper positions and fan speed. What conditions or events cause the fan speed to modulate and did you say the normal operating residual o2 runs between 10 and 16%.

thanks

tom

So you used those standards when you came up with your efficency numbers? 92% wouldnt the boiler be condensing at that point?

Thanks for that. Although we have the same boiler it is hard for me and my limited experience to compare since our set up is pretty different. I've only made changes two settings. My slumber temp is 90c ( i think 85 or 87 was the default) and there was a timer setting that Tarm walked me though changing in the service menu. I was getting some erroneous "boiler has air leak" message related to the residual oxygen readings. I was burning some real gnarly pieces of wood at the beginning of the season and as a safety, the boiler was interpreting the high residual oxygen content settings as a leak, or leaving a door open. Once Tarm walked me through the change I never got the message again.

With 220 c flu gas temp I hit 64% on the secondary last night. Our TV room is in the basement, and when I really hear it rumbling I go out for a look. My wife thinks it's dorky as anything, but like I said, I'm a gadget guy and just generally curious about these kind of things.

Hiker & Dan, I am curious, at startup what are the p/s damper positions and fan speed. What conditions or events cause the fan speed to modulate and did you say the normal operating residual o2 runs between 10 and 16%.

thanks

tom