Brotherbart asked about larger stoves and burning smaller fires so i thought i would branch this thread off from the "Falling creosote" thread.

https://www.hearth.com/econtent/index.php/forums/viewthread/5724/P0/

[quote author="ozarkjeep" date="1170382039"]I was told that at a local stove retailer also, "better to have a small stove and burn it hot, than a large stove dampered down"

But, could you not use a large stove, and build smaller fires and let them burn hot?

then if you NEEDED the full output you would have it? [/quote]

Exactly.

How does one tell if there stove it too big ?

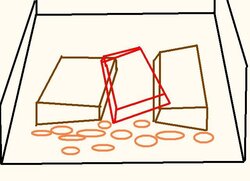

You cant run the same size fire year around , it dont work like that. I dont need to full size of my firebox 75% of the time (3.0 cf) but when it gets 15° and lower the large fire box is needed. Woodstoves dont work like you home furnace and put out just one set BTU and then turns on and off as needed. One have to have a wide range of heat output from there stove to heat there home from 50° through -15° and with a wood stove your have to have different size fires , different loads.

This is an issue of so many people under sizing there stove and cant get the proper heat out put when it gets really cold , they run out of stove / size / fire box and it also shortens over night burn times.

https://www.hearth.com/econtent/index.php/forums/viewthread/5724/P0/

[quote author="ozarkjeep" date="1170382039"]I was told that at a local stove retailer also, "better to have a small stove and burn it hot, than a large stove dampered down"

But, could you not use a large stove, and build smaller fires and let them burn hot?

then if you NEEDED the full output you would have it? [/quote]

Exactly.

How does one tell if there stove it too big ?

You cant run the same size fire year around , it dont work like that. I dont need to full size of my firebox 75% of the time (3.0 cf) but when it gets 15° and lower the large fire box is needed. Woodstoves dont work like you home furnace and put out just one set BTU and then turns on and off as needed. One have to have a wide range of heat output from there stove to heat there home from 50° through -15° and with a wood stove your have to have different size fires , different loads.

This is an issue of so many people under sizing there stove and cant get the proper heat out put when it gets really cold , they run out of stove / size / fire box and it also shortens over night burn times.

) will create a small but very hot fire but with a shorter overall burn time and less overall heat. Those fires are a bit more peaky than full loads, but you could even that out with a soapstone stove. My stove will get quite hot at first, then drop off and even out after that. Another thing to do is pay attention to the type of wood. 3 splits of oak done like Spike says will give you a longer burn and coal stage than white pine.

) will create a small but very hot fire but with a shorter overall burn time and less overall heat. Those fires are a bit more peaky than full loads, but you could even that out with a soapstone stove. My stove will get quite hot at first, then drop off and even out after that. Another thing to do is pay attention to the type of wood. 3 splits of oak done like Spike says will give you a longer burn and coal stage than white pine.