Howdy,

This has been a busy summer. I bought a Craftsman 3kpsi/2.7gpm power washer for some pretty serious use about four times a year. Build code says 2009.

Late last year I thought I was smelling gas but couldn't pin it down. This year it became clear to me that it was leaking at the seam between the bottom and top half of the tank. Of course the tank is plastic. I thought I'd get a close look at it today and find a replacement tank. I had seen a replacement tank selling for around $70!! Shocking. Maybe this is a $300 unit...

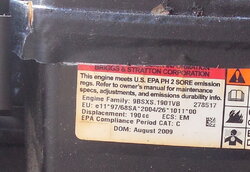

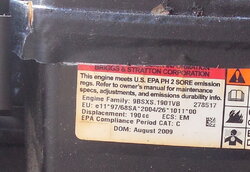

To add insult to injury, I could not get the B&S engine to show up online anywhere. No matter what numbers I key in, I don't get a definitive return.

Back to our story, after I get enough stuff apart to get to the tank, for the life of me, it doesn't look like it's ever supposed to come off. What the Sam Hill is going on?

Have I correctly surmised that this tank is inextricably wedded to this engine? I don't see any way that any of the support posts further disassemble. Here are some shots.

Just because you took the time to read, here are a few shots of our snakes. They seem to be working just fine...

Thanks,

Greg

This has been a busy summer. I bought a Craftsman 3kpsi/2.7gpm power washer for some pretty serious use about four times a year. Build code says 2009.

Late last year I thought I was smelling gas but couldn't pin it down. This year it became clear to me that it was leaking at the seam between the bottom and top half of the tank. Of course the tank is plastic. I thought I'd get a close look at it today and find a replacement tank. I had seen a replacement tank selling for around $70!! Shocking. Maybe this is a $300 unit...

To add insult to injury, I could not get the B&S engine to show up online anywhere. No matter what numbers I key in, I don't get a definitive return.

Back to our story, after I get enough stuff apart to get to the tank, for the life of me, it doesn't look like it's ever supposed to come off. What the Sam Hill is going on?

Have I correctly surmised that this tank is inextricably wedded to this engine? I don't see any way that any of the support posts further disassemble. Here are some shots.

Just because you took the time to read, here are a few shots of our snakes. They seem to be working just fine...

Thanks,

Greg

Can you believe the gas tank for this thing is $71?? That's 25% of the purchase price!! I see it for a few bucks less here and there, but still....

Can you believe the gas tank for this thing is $71?? That's 25% of the purchase price!! I see it for a few bucks less here and there, but still....