Hi All:

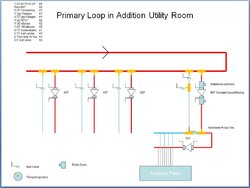

A quick question regarding primary/secondary "connection". I'm hooking up my radiant tubing manifolds in my addition floor to the primary loop as the photo below indicates. I have closely spaced tees in both the primary and secondary. Does the length of pipe between the primary and secondary loops matter, i.e. the 3/4" copper with my mixing pump? In this layout I'm putting together, the distance would only be just a bit more than the pump with the iso flanges, i.e. less than 2 feet total, in the 3/4" between the primary 1.25" and the secondary 1". I'm a bit worried that the primary might pump through this short of a distance a bit, even though the tees are closely spaced.

Also, has anyone used those Webstone purge tees? A closely spaced tee with an integral valve, great for initial fill to purge off the air. They are spaced so closely, the return line is very close to the pump and the supply line. With the iso flanges on the pump, seems like things are within 1/4" of each other (some part of the pump and the return line). Is that just how it is? Steve, I know you have used thousands of these by now....

Thanks,

Bruce

A quick question regarding primary/secondary "connection". I'm hooking up my radiant tubing manifolds in my addition floor to the primary loop as the photo below indicates. I have closely spaced tees in both the primary and secondary. Does the length of pipe between the primary and secondary loops matter, i.e. the 3/4" copper with my mixing pump? In this layout I'm putting together, the distance would only be just a bit more than the pump with the iso flanges, i.e. less than 2 feet total, in the 3/4" between the primary 1.25" and the secondary 1". I'm a bit worried that the primary might pump through this short of a distance a bit, even though the tees are closely spaced.

Also, has anyone used those Webstone purge tees? A closely spaced tee with an integral valve, great for initial fill to purge off the air. They are spaced so closely, the return line is very close to the pump and the supply line. With the iso flanges on the pump, seems like things are within 1/4" of each other (some part of the pump and the return line). Is that just how it is? Steve, I know you have used thousands of these by now....

Thanks,

Bruce