Long story short, I'm expecting my Garn Jr. delivered and with the help of heaterman installed yet this year, but really I'm just getting started. I can hear my propane furnace firing as I'm typing this, so you can say I'm getting a little excited for my new system!

I'm sold on the foam in trench method, so in preparation to lay and insulate the lines, I started to dig to locate my propane line as I will need to cross it at some point. Needless the say, I didn't find it (someone is scheduled for Tuesday to mark it out) but ended with a nice size hole. Now, I knew that I had clay and what I see since digging early this week, along with some good rain, is not a huge surprise...standing water! Especially in the spring and fall, I can dig a hole and have a pond.

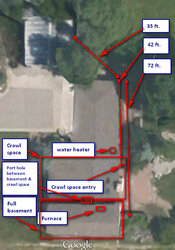

The trench I will be digging is by a full-size back-hoe, probably 24". I have foam board I will using to make a path to contain only the necessary amount of foam, instead of filling the entire trench. Of course, I'll be using closed cell foam and also plan to line with plastic.

My question is, will I be okay still having so much water retention in the ground during certain times of the year? If what I'm doing won't work, I can't imagine what will! Thanks!

I'm sold on the foam in trench method, so in preparation to lay and insulate the lines, I started to dig to locate my propane line as I will need to cross it at some point. Needless the say, I didn't find it (someone is scheduled for Tuesday to mark it out) but ended with a nice size hole. Now, I knew that I had clay and what I see since digging early this week, along with some good rain, is not a huge surprise...standing water! Especially in the spring and fall, I can dig a hole and have a pond.

The trench I will be digging is by a full-size back-hoe, probably 24". I have foam board I will using to make a path to contain only the necessary amount of foam, instead of filling the entire trench. Of course, I'll be using closed cell foam and also plan to line with plastic.

My question is, will I be okay still having so much water retention in the ground during certain times of the year? If what I'm doing won't work, I can't imagine what will! Thanks!