It's been a good while since checking in on the forum, but after more than two years of digging around and researching options, I decided to go with a Lopper Drummer 45 boiler. This was to replace my much loved and faithful Tarm Solo Plus 140 that served me for some 9 years but was not up to the heat load demands of the homestead after I added 1200 sq. ft. of heated space. I also replaced the 800 gallon heat sink with a 2000 gallon heat sink (unpressurized). The install was completed in August and I am now able to report on my experience.

(I will be brief, but am happy to answer questions that may occur to forum members--though I am an amateur compared to many of you!)

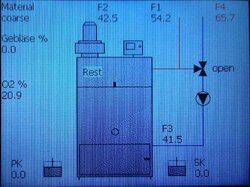

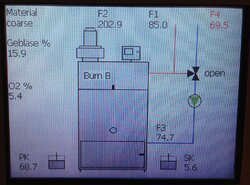

The first couple of months involved a significant learning curve. The Lopper has a sophisticated computer-controlled interface that monitors a range of data, including: O2 content, flue gas temp, fan rotation speed, supply temp, return temp, heat sink temp, primary damper opening and secondary damper opening. All of these (and more) have settings that can be adjusted and fine-tuned. (Beginning with whether you are burning cordwood or chips--you can burn either.)

Getting it 'right' involved experimenting with different settings and observing how the system managed. I cannot say enough positive things about the support and help that I received from Mark and Ray at

http://www.loppernorthamerica.com/ during the learning curve.

I also need to acknowledge the help of Tom at http://www.americansolartechnics.com/, who went way beyond the call of duty when he provided the custom liner for my homemade 2000 gallon heat sink.

Bottom line is that the system is working great. Even at -40C/F, the Lopper has been more than able to keep up with my heat load. And, over all, I am burning less wood than with my old system. (The Tarm needed to be 'helped out' by also having a fire on the Vermont Castings woodstove in the Great Room--this is no longer needed.)

The Lopper is extraordinarily well built with a large and easily loadable burn chamber. Among other features that I appreciate is that the draft fan is on the exhaust gas side of the boiler, effectively sucking air into the burn chamber and pushing it out the flue. This allows the firebox to have a top loading door, through which you literally can drop the wood into the firebox. When the loading door is opened, the fan goes to max % rotation, sucking the smoke down and allowing for a virtually smoke-free loading experience. (This was definitely not my experience with the Tarm, and is much appreciated.)

That's about it. There are a growing number of good wood-gasification boilers out there, but I am very happy with my decision to go with the Lopper Drummer 45.

(I will be brief, but am happy to answer questions that may occur to forum members--though I am an amateur compared to many of you!)

The first couple of months involved a significant learning curve. The Lopper has a sophisticated computer-controlled interface that monitors a range of data, including: O2 content, flue gas temp, fan rotation speed, supply temp, return temp, heat sink temp, primary damper opening and secondary damper opening. All of these (and more) have settings that can be adjusted and fine-tuned. (Beginning with whether you are burning cordwood or chips--you can burn either.)

Getting it 'right' involved experimenting with different settings and observing how the system managed. I cannot say enough positive things about the support and help that I received from Mark and Ray at

http://www.loppernorthamerica.com/ during the learning curve.

I also need to acknowledge the help of Tom at http://www.americansolartechnics.com/, who went way beyond the call of duty when he provided the custom liner for my homemade 2000 gallon heat sink.

Bottom line is that the system is working great. Even at -40C/F, the Lopper has been more than able to keep up with my heat load. And, over all, I am burning less wood than with my old system. (The Tarm needed to be 'helped out' by also having a fire on the Vermont Castings woodstove in the Great Room--this is no longer needed.)

The Lopper is extraordinarily well built with a large and easily loadable burn chamber. Among other features that I appreciate is that the draft fan is on the exhaust gas side of the boiler, effectively sucking air into the burn chamber and pushing it out the flue. This allows the firebox to have a top loading door, through which you literally can drop the wood into the firebox. When the loading door is opened, the fan goes to max % rotation, sucking the smoke down and allowing for a virtually smoke-free loading experience. (This was definitely not my experience with the Tarm, and is much appreciated.)

That's about it. There are a growing number of good wood-gasification boilers out there, but I am very happy with my decision to go with the Lopper Drummer 45.