I've got a real beat up old copy, (and a pristine reprint) This ones a sweet trip too! Uncle-Louies-Fantastic-Sea-VoyageMike loved his MaryAnne.

We have the book.

MaryAnne the Tarm MB30 looking for all the Mike Mulligans

- Thread starter aka.bugle

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

webbie

Seasoned Moderator

arbutus

Feeling the Heat

I haven't seen that one. I'll ask my wife to see if the library has it the next time she takes the kids (once every other week).I've got a real beat up old copy, (and a pristine reprint) This ones a sweet trip too! Uncle-Louies-Fantastic-Sea-Voyage

Katy and the Big Snow is another good one by the same author as Mike Mulligan. Our copies of both these books are very old, but the kids love them.

My apologies for the hijacking.

700renegade

Member

air separator belongs on the lowest pressure, hottest part of the system - normally this would be just above the boiler ( especially if you were 'pumping away'. most of us with ladomatt or danfoss cannot do this ).

Since your tanks are already stacked vertically why not take advantage of the stratification benefits? And if the piping is done right you shouldn't need the automag you mentioned in the first post.

I'm not sure why the air-trolls are needed in this system. Perhaps I have something to learn.

Personally I wouldn't want autofill. If I need to add a few gallons I'd want to know it happened because I did it manually.

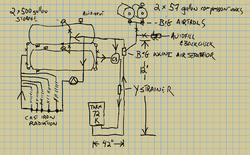

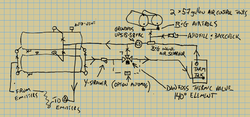

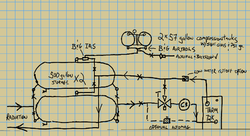

This is how I see this system:

Since your tanks are already stacked vertically why not take advantage of the stratification benefits? And if the piping is done right you shouldn't need the automag you mentioned in the first post.

I'm not sure why the air-trolls are needed in this system. Perhaps I have something to learn.

Personally I wouldn't want autofill. If I need to add a few gallons I'd want to know it happened because I did it manually.

This is how I see this system:

Attachments

Last edited:

ewdudley

Minister of Fire

Ditto, ditto, ditto. (I would add only that 'pumping away' is not relevant in a boiler-storage loop with fat short pipes. (air separator belongs on the lowest pressure, hottest part of the system - normally this would be just above the boiler ( especially if you were 'pumping away'. most of us with ladomatt or danfoss cannot do this ).

Since your tanks are already stacked vertically why not take advantage of the stratification benefits? And if the piping is done right you shouldn't need the automag you mentioned in the first post.

I'm not sure why the air-trolls are needed in this system. Perhaps I have something to learn.

Personally I wouldn't want autofill. If I need to add a few gallons I'd want to know it happened because I did it manually.

This is how I see this system:

Last edited:

Renegade... Thank you! are you showing in your pdf the expansion tanks connected at the cold return? I guess I don't understand how a spirovent works ???... I'm showing a B&G Inline Air Sep' at the hot side of the boiler, B&G airtrols and expansion tanks 3/4" pipe from top of B&G IAS.

ewdudley...

ewdudley...

I'm at 1+1/4" and under 30' .... wahoo! (and the automag is nixed, returned and restocked in New Hampshire)(I would add only that 'pumping away' is not relevant in a boiler-storage loop with fat short pipes. (1.0" or larger, 30 ft or shorter round trip, 20 gpm or less.)

Last edited:

ewdudley

Minister of Fire

I think the B&G air separator and Renegade's Spirovent accomplish the same function of separating gas from the flow leaving the boiler. Renegade has added a separate line for expansion water that should be helpful because the water flow to the expansion tank would be cooler and waste a little less heat. Also note that Renegade's design has a line from the top of one tank to the other, which is necessary to equalize the water levels in the tanks.Renegade... Thank you! are you showing in your pdf the expansion tanks connected at the cold return? I guess I don't understand how a spirovent works ???... I'm showing a B&G Inline Air Sep' at the hot side of the boiler, B&G airtrols and expansion tanks 3/4" pipe from top of B&G IAS.

I was attempting to invent a rule of thumb for when not to worry about 'pumping away', I've since backpedaled to say don't worry about it if pump head is fairly low.ewdudley... I'm at 1+1/4" and under 30' .... wahoo! (and the automag is nixed, returned and restocked in New Hampshire)

I'm not sure why the air-trolls are needed in this system. Perhaps I have something to learn.

I may not have this right, but I think the big thing an Airtrol can do for a system is to prevent a small gentle thermosiphon of hot water up one side of the pipe to the non-bladder expansion tank and a corresponding flow of cool water down the other side. The hot water can absorb gas as it cools in the expansion tank and will deliver the absorbed gas back into the system via the cold water flow, which can add up over the years. Airtrols have a chamber that acts as a thermal trap to prevent this flow.

Last edited:

700renegade

Member

I may not have this right, but I think the big thing an Airtrol can do for a system is to prevent a small gentle thermosiphon of hot water up one side of the pipe to the non-bladder expansion tank and a corresponding flow of cool water down the other side. The hot water can absorb gas as it cools in the expansion tank and will deliver the absorbed gas back into the system via the cold water flow, which can add up over the years. Airtrols have a chamber that acts as a thermal trap to prevent this flow.

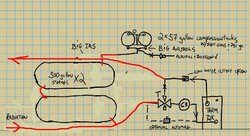

If you purchase a Taco Vortech ( I accidentally named it a Hyvent in my diagram as an alternative to the Spirovent ) you can peel the high capacity Hy-Vent auto vent out of the top of it. ( 3/4" mpt ) Put the salvaged vent on top of your storage or wherever else you need it. Run the lines like I show them and for the most part you'll have lukewarm water fed to the expansion tanks and the driver for the thermosiphon is gone. use a 1/2" pex to feed the expansion tank pair and put a thermal trap in the line as it rises if you wish.

Should save you a bunch of money in parts and with any luck it might even work.

p.s. - if you try to remove the #419 Hy-vent realize you cannot spin it out by conventional means. If you try to put a pipe wrench on the valve body you are sure to crush it as it's very thin brass. You may have to drive it out by inserting a 1/2" nipple on the internal threads and hope it's not in that cast body too tight

Last edited:

ewdudley

Minister of Fire

Seems like this would definitely eliminate the need for the Airtrol fittings. I'm still having a hard time believing that the thermosiphon thing is a real problem in the first place, especially when connecting to the return line with small diameter pipe, but I suppose it can't hurt to play along with the teachings of the ancients by adding a heat trap in the piping.Run the lines like I show them and for the most part you'll have lukewarm water fed to the expansion tanks and the driver for the thermosiphon is gone. use a 1/2" pex to feed the expansion tank pair and put a thermal trap in the line as it rises if you wish. Should save you a bunch of money in parts and with any luck it might even work

Last edited:

maple1

Minister of Fire

I've got my wye-strainer just upstream of the cold return to my loading unit, between the loading unit & the bottom of the storage tanks.

Chances are the best potential for dirt would be coming out of the bottom of storage, and the most expensive component in the circuit is the loading unit - so I put 2 & 2 together & got that.

Chances are the best potential for dirt would be coming out of the bottom of storage, and the most expensive component in the circuit is the loading unit - so I put 2 & 2 together & got that.

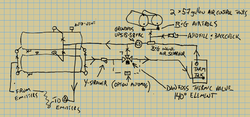

Ok now.... I've sent the LK810 back to the supplier (I can't afford a new Mercedes either!) I'm going with a cast iron Grundfos circulator on the supply from the boiler (same specs as the bronze LK810 unit) and a Danfoss thermic valve fitted with a 140 deg. element on the return. I plan on using a battery backup UPS for the circulator in lieu of the automag for power loss/ heat dump situations.... Comments?

700renegade

Member

The C3 circulator is traditionally between the Danfoss mix valve and the boiler, and the Automag piping would span across both the Danfoss and the pump. If you leave the check valve in the pump you will get no thermosiphon the way you show it now.

I'm still not sure why the Airtrols are there, and would stand the storage tanks on end if I had ceiling height. Most guys here aren't crazy about autofill. I'd rather have a sight gauge on my expansion tanks and do it manually.

I'd also put the expansion tanks vertical if possible to minimize the area of air/water interface.

I'm still not sure why the Airtrols are there, and would stand the storage tanks on end if I had ceiling height. Most guys here aren't crazy about autofill. I'd rather have a sight gauge on my expansion tanks and do it manually.

I'd also put the expansion tanks vertical if possible to minimize the area of air/water interface.

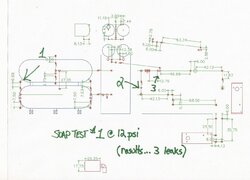

I've got to raise my compression tanks up to get a air control line from the storage tanks sloped up a minimum 1" in 5'. I've got room, heave ho! And What do you guys think about getting rid of the autovents in the storage altogether? forgot to put the y strainer in the sketch (on the return from the storage tanks before Danfoss 140* .) The automag is an option I probably won't do as I have a 600 watt UPS to run the circulator in the event of power loss. (happens all the time here in the Endless Mtns, PA)

Last edited:

ewdudley

Minister of Fire

I think it's been mentioned above but may bear repeating; system return/boiler return connect to bottom of lower tank, system supply/boiler supply connect to top of upper tank, top of lower tank connects to bottom of upper tank.

I get that... is that not what I've shown?I think it's been mentioned above but may bear repeating; system return/boiler return connect to bottom of lower tank, system supply/boiler supply connect to top of upper tank, top of lower tank connects to bottom of upper tank.

700renegade

Member

No - you are showing the tanks in parallel, not series.I get that... is that not what I've shown?

maple1

Minister of Fire

iceguy4

Minister of Fire

It is expensive...but well worth it! I paid $900+ for 5 radiators to be done..ALL casting roughness was covered by what looks like a ceramic coating...there like a bath tubMobile sandblaster sounds like a great idea, mind if I ask what you paid? I need to get mine redone, and I was going to send them out to be blasted and powdercoated to get the years of housepaint someone put on them off....but the cost was outrageous....buy my own sandblaster and compressor that could run it outrageous.

Last edited:

maple1

Minister of Fire

Are your tanks stacked?

storage... piggy back in parallel.

air control ... tandem side by side

Barnheat

New Member

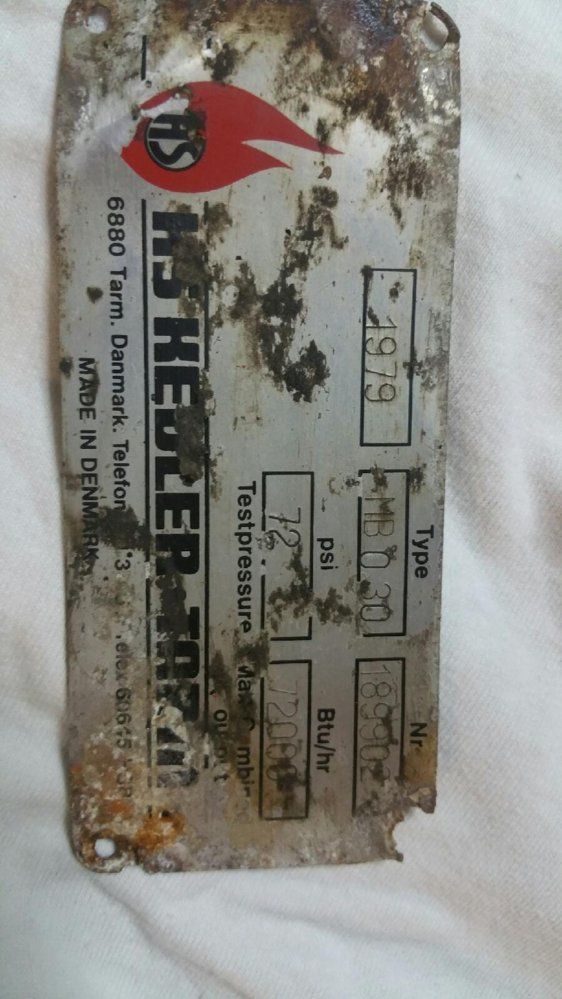

Everyone, I apologize for breaking into an old post and I can only hope that someone sees this. I have just been given a MB 0 30 boiler and I know nothing about it. I need a manual and to learn how it works. It is old but fully functional and only being replaced by a new one after many years of service. It have been in my son in-laws, fathers, garage for a long time and still works. I am in the process of building a barn in Maine and thought since he was going to give it to me it was worth looking into how it works. He said he will burn oil, coal and wood and put off a lot of heat at 72,000 BTU and would keep the barn warm during the cold winter months. Does anyone have a manual or can tell me where to get one? This is photo of the Info Plate:

- Status

- Not open for further replies.

Similar threads

- Replies

- 26

- Views

- 2K

- Replies

- 2

- Views

- 818

- Replies

- 34

- Views

- 6K

- Replies

- 3

- Views

- 2K