brenndatomu

Minister of Fire

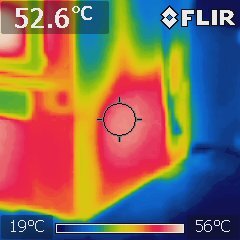

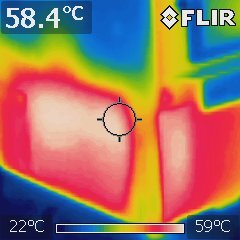

If you have a infrared thermometer you can get an accurate reading by putting some small pieces of black electrical tape on the spots where you want to take a temp sample, aim the IRT exactly at that spot, the flat black of the tape gives a good read. I suppose you could paint the plenum/duct flat or satin black to get a good read with the FLIR too...See IR picture... (111C = 232F) not sure if temp result is accurate, there was lot of parameter in this IR device that was making a big difference of the temp reading (metal reflection)

If that 232* is accurate I hope you have the proper CTC on your ductwork because that temp is getting in to pyrolysis territory there!