Hi, I'm from Michigan and will be burning with my Merrimack for my 4th season already. I have made several improvements to the insert.

#1 has been putting vinyl tubing underneath the fan motor to prevent it from vibrating like a jack hammer.

#2 splicing the thermostat sensor wires together to be able to turn the fan on and off whenever I want. 10 min after starting a good fire I have decent hot air that would be a shame to waste.

#3 bringing in fresh make-up air through the back of my fireplace masonary using metal pipes. They stay hidden as they go around the side and then through the the removable electric cord panel that can be removed effect to the unit. Nice to not have to use room air to combust. Hey, why heat it if you just blow half of it back up the chimney right?

#4 Insulated my 23 foot long 6 inch dia. flue with 1/2 chimney flue insulation for better draft. Two fires in and I'm not sure it make much of a difference.

Still have a couple problems:

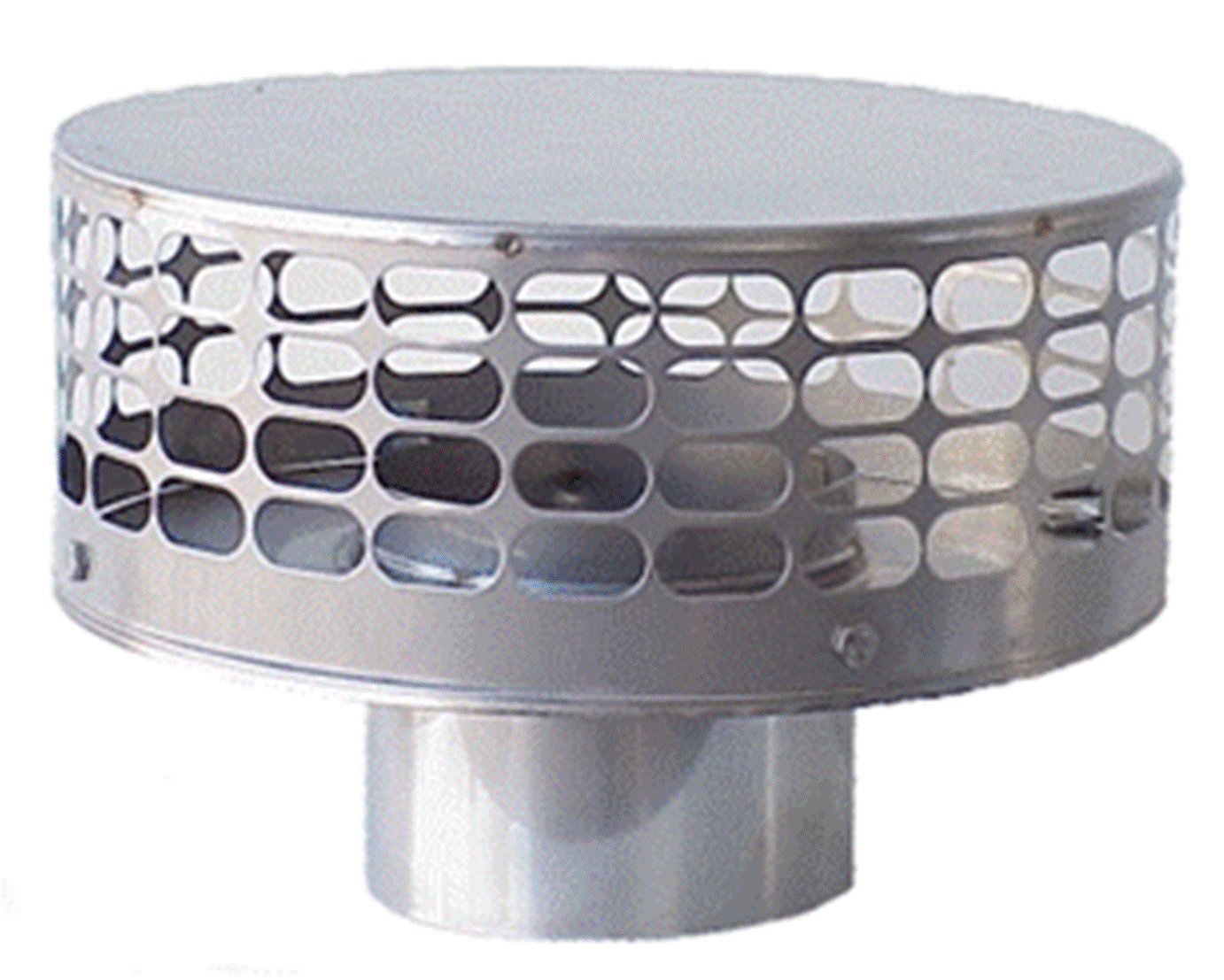

Some smoke comes out when the doors are opened for loading. It is enough to bother me and and my wife. I can open the doors about 3-4 inches then the smoke starts to leak out. I was hoping that the flue insulation would have helped this problem out. Gasket at the top of the insert to the flue coupler seems good but maybe I need to redo the glass rope. This is my last ditch idea. I may think about a chimney top power vent for $1000 bucks. Any recommendations? Till then, I just wait till I have coals then I load.

I have about 2200 square feet to heat. I can heat the first floor to near 80, but the upstairs stays cool/cold. I'm looking at ways to distribut the heat more. Cutting vent holes in the ceiling to have a passage for the heat. Not sure about code or whether that would be annoying to have sound travel between floors. I run the furnace fan and it does an ok job circulating some heat but most of the heat stays near the ceiling of the room. A ceiling fan may work but it would look weird and our ceilings are low already.

I have had to replace the fan and door gaskets. Factor a $200 fan every 3 years into your payback for this unit. Seems the fan is a poor design. Hopefully you are a bit handy and can put the fan in yourself or it could get very expensive.

Good luck Merrimack owners. Let me know how you are doing out there. Especially with any smoke while loading logs to an established fire. If you do have smoke tell me more about it and your flue dimensions. No smoke, also tell me what your flue looks like.

#1 has been putting vinyl tubing underneath the fan motor to prevent it from vibrating like a jack hammer.

#2 splicing the thermostat sensor wires together to be able to turn the fan on and off whenever I want. 10 min after starting a good fire I have decent hot air that would be a shame to waste.

#3 bringing in fresh make-up air through the back of my fireplace masonary using metal pipes. They stay hidden as they go around the side and then through the the removable electric cord panel that can be removed effect to the unit. Nice to not have to use room air to combust. Hey, why heat it if you just blow half of it back up the chimney right?

#4 Insulated my 23 foot long 6 inch dia. flue with 1/2 chimney flue insulation for better draft. Two fires in and I'm not sure it make much of a difference.

Still have a couple problems:

Some smoke comes out when the doors are opened for loading. It is enough to bother me and and my wife. I can open the doors about 3-4 inches then the smoke starts to leak out. I was hoping that the flue insulation would have helped this problem out. Gasket at the top of the insert to the flue coupler seems good but maybe I need to redo the glass rope. This is my last ditch idea. I may think about a chimney top power vent for $1000 bucks. Any recommendations? Till then, I just wait till I have coals then I load.

I have about 2200 square feet to heat. I can heat the first floor to near 80, but the upstairs stays cool/cold. I'm looking at ways to distribut the heat more. Cutting vent holes in the ceiling to have a passage for the heat. Not sure about code or whether that would be annoying to have sound travel between floors. I run the furnace fan and it does an ok job circulating some heat but most of the heat stays near the ceiling of the room. A ceiling fan may work but it would look weird and our ceilings are low already.

I have had to replace the fan and door gaskets. Factor a $200 fan every 3 years into your payback for this unit. Seems the fan is a poor design. Hopefully you are a bit handy and can put the fan in yourself or it could get very expensive.

Good luck Merrimack owners. Let me know how you are doing out there. Especially with any smoke while loading logs to an established fire. If you do have smoke tell me more about it and your flue dimensions. No smoke, also tell me what your flue looks like.

!

!