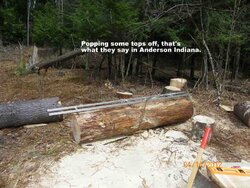

Milling Done Today

- Thread starter thewoodlands

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Backwoods Savage

Minister of Fire

It's slow work that way but still does the job. You will always look at those boards a bit different now too because you made them. If you get the weather tomorrow that we had today, you can mill away! Rain all missed us.

I think Sunday is suppose to be a good day, if it rained that would be ok, we need it bad. The nice thing about milling is we have some nice benches we can use around the property.

zap

zap

Thistle

Minister of Fire

Looks great Zap. I dont mind pushing the saw though I'll run out of steam long before it will. Unless you get that remote trigger thing set up with the small boat winch where you can set down 10ft away & relax while turning that crank handle -milling takes a toll on the back,leaning over & pushing that saw through much more than regular crosscutting.

Unless you get that remote trigger thing set up with the small boat winch where you can set down 10ft away & relax while turning that crank handle -milling takes a toll on the back,leaning over & pushing that saw through much more than regular crosscutting.

Just like everything else,1 board at a time & you gradually finish the job.

Unless you get that remote trigger thing set up with the small boat winch where you can set down 10ft away & relax while turning that crank handle -milling takes a toll on the back,leaning over & pushing that saw through much more than regular crosscutting.

Unless you get that remote trigger thing set up with the small boat winch where you can set down 10ft away & relax while turning that crank handle -milling takes a toll on the back,leaning over & pushing that saw through much more than regular crosscutting.Just like everything else,1 board at a time & you gradually finish the job.

Thanks Thistle. What brand ripping chain do you use and how many boards do you do (softwood) before changing.

zp

zp

Thistle

Minister of Fire

Thanks Thistle. What brand ripping chain do you use and how many boards do you do (softwood) before changing.

zp

Oregon DP72 .050 gauge Semi-Chisel,every 3rd tooth ground off for the occasional dirty or abrasive wood,Oregon JG72 0.50 gauge Skiptooth,Oregon JG75.063 gauge Skiptooth for everything else. All ground at 10 degrees.

Most softwood I've done is Eastern Red Cedar thats clean but knotty,lengths rarely over 4 feet.I can usually get 5-6 boards or slabs before chain needs filing.The 80 yr old Western Red Cedar telephone pole I milled was done with an old semi-chisel,1 7ft long cut & it needed filed again

No nails or anything,just that end buried in the ground wasnt a bit clean. Went very fast though,compared to the White/Bur Oak,Walnut,Hickory & occasional Mulberry or Silver Maple I'm usually getting.

No nails or anything,just that end buried in the ground wasnt a bit clean. Went very fast though,compared to the White/Bur Oak,Walnut,Hickory & occasional Mulberry or Silver Maple I'm usually getting.

K

katwillny

Guest

amateur cutter

Minister of Fire

Looking good Zap! Wish I had time to take up some milling. No clue on the holes LOL, but I do know that around here, wormy maple is a desirable board for some purposes. A Ckatwillny, remember when parents would pay extra for jeans that had been shot by a shotgun, how much extra per bug hole do you think I can get?

zap

Thanks AC, I decided today would be spent cleaning the saws,bars,the back of the rhino and the garage floor. Looks like I might try milling after work this week some night so I can get another 10-12 boards by the end of next weekend.

zap

zap

woodsmaster

Minister of Fire

Wow your at it again.  You might want to consider getting a band saw to speed things up as much milling as you do. Looks real nice !

You might want to consider getting a band saw to speed things up as much milling as you do. Looks real nice !

You might want to consider getting a band saw to speed things up as much milling as you do. Looks real nice !

You might want to consider getting a band saw to speed things up as much milling as you do. Looks real nice !Woodsmaster, we almost pulled the trigger on one about a year ago, just so many good size hills on our property that the ACM was a better answer.

zap

zap

woodsmaster

Minister of Fire

I'm not sure but my guess it would be, http://www.forestryimages.org/browse/subthumb.cfm?sub=398&desc=7

zap

zap

In the picture labeled the last board of the day the plan is to mill a two inch thick slab for our coffee table for the basement. I'll need to coat the ends so what is the best option for sealing the ends, do I need to seal the whole slab?

zap

zap

smokinj

Minister of Fire

In the picture labeled the last board of the day the plan is to mill a two inch thick slab for our coffee table for the basement. I'll need to coat the ends so what is the best option for sealing the ends, do I need to seal the whole slab?

zap

If I was making furniture it would be hot wax ends. One step further would be to wax the sides and 4 inchs out from all edges.

Looks like I'll look for some old candles along with checking out our local True Value for some Paraffin.

Thanks

Zap

Thanks

Zap

smokinj

Minister of Fire

Looks like I'll look for some old candles along with checking out our local True Value for some Paraffin.

Thanks

Zap

Hobby loby's where I get it. Dont know if you have one but around 10.00 for a 2.5 block. I have a old crock pot I melt it in and brush it on.

smokinj

Minister of Fire

182 miles away in New Hartford, NY.

Zap

As we said all day yesterday Easy Peasy.....As that oak cracked my back again.

smokinj

Minister of Fire

Are you cutting or milling Oak?

zap

Cutting a monster oak. We turn 4.5 cords off it so far. (Some got stolen to, mabe a cord) And at-least 3 cords left. Looking like a 8 cord tree. 49 inchs and over 130ft tall.

smokinj

Minister of Fire

Nice, how do you like the 460 in that Oak?

zap

Its cutting it like always very fast. Noodling every big rounds into quarters to. James has step-up on this one and has 100 percent on the saw. (Cleaning sharpening and bar slection) This is his first time 100 percent with very little instruction. Even the noodles looks like mine.

James 08-15-2009 this is the first year we would run the 460.

James 08-15-2009 this is the first year we would run the 460.

S

ScotO

Guest

Zap those boards look great. Every time I see your milling pics o get antsy to try it myself. We're cutting a huge norway maple right now at a job, gonna get to use the 051AV for that trunk. I think I'll try milling that poplar on a job we have coming up in June. Two huge poplars, almost 4' diameter and both at least 80-90ft high. Lots of boards in those two trees, easily enough to build my woodshed.

- Status

- Not open for further replies.

Similar threads

- Replies

- 15

- Views

- 1K

- Replies

- 2

- Views

- 410