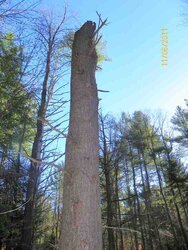

Had a nice size pine mother nature took down a few years back that I started today, the three sections that I'm milling were off the ground so they are still good. Still have to finish up these then drop whats still standing then mill that, all these will be floor joist for the planned cabin build.

Attached are some pictures.

zap

Attached are some pictures.

zap