A safe guideline is to go no larger than 80 % of your cylinder exhaust port. You have to measure and calculate the area of both and figure out how much more you need to open your exhaust hole.

From another site it seems that 6 .25 hole are pretty normal for a 290..

Now not recommend by me but this comes from someone with way more experience then I " ultimately, your trying to IMPROVE the flow of the muffler. If the INLET of the muffler is 800 cubic mm, and the outlet of the muffler is 100 cu mm, there's an OBVIOUS restriction... try and land your outlet size close to 80% or so of exhaust port (at the cylinder wall) size... you can go up to 100% if your still using the spark screen..."

As for the 046 running a 3/4 inch port I bet if I measure the hole in my dp and the factory holes on the side it will be well over 3/4 inch and that is all factory no mods by me... Now I know you got one of those expensive modded muffs but I would be willing to bet it could be opened a little more...

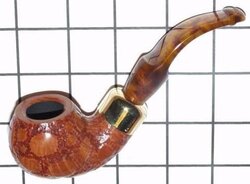

O and I was a BIG fan of Savinelli back in my smoking days.......I got a alligator that I loved....

From another site it seems that 6 .25 hole are pretty normal for a 290..

Now not recommend by me but this comes from someone with way more experience then I " ultimately, your trying to IMPROVE the flow of the muffler. If the INLET of the muffler is 800 cubic mm, and the outlet of the muffler is 100 cu mm, there's an OBVIOUS restriction... try and land your outlet size close to 80% or so of exhaust port (at the cylinder wall) size... you can go up to 100% if your still using the spark screen..."

As for the 046 running a 3/4 inch port I bet if I measure the hole in my dp and the factory holes on the side it will be well over 3/4 inch and that is all factory no mods by me... Now I know you got one of those expensive modded muffs but I would be willing to bet it could be opened a little more...

O and I was a BIG fan of Savinelli back in my smoking days.......I got a alligator that I loved....