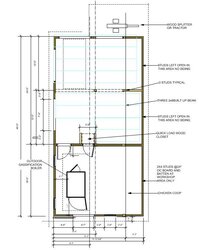

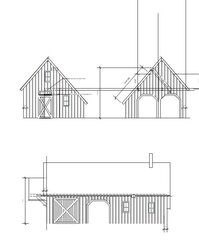

Took my vacation this week to rebuild my woodshed boiler room. Lost the orignal one to a breakdown in zero clearance chimney. This one is bigger. This will also hold a workshop, tractor storage, two bays for different ages of wood. This is 4 days work for two men. its 20 x 40

The steel roofing is nice, its not the regular stuff we get here, its the old fashioned 5vcrimp that costs the same as the regular stuff. found some fiberglass 5v crimp to add light at workshop and in wood storage area.

This is quite an investement..but I dont have any type of workshop area...my garage is a carport kind of thing. anyway if there is interest i will keep posting progress. picture may be bad, i had a heck of a time reducing the size and it kept saying the size was too big when it wasnt!

barkeatr

The steel roofing is nice, its not the regular stuff we get here, its the old fashioned 5vcrimp that costs the same as the regular stuff. found some fiberglass 5v crimp to add light at workshop and in wood storage area.

This is quite an investement..but I dont have any type of workshop area...my garage is a carport kind of thing. anyway if there is interest i will keep posting progress. picture may be bad, i had a heck of a time reducing the size and it kept saying the size was too big when it wasnt!

barkeatr