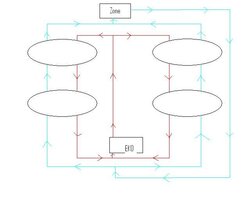

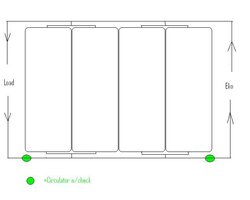

I've lucked out and have located four 500 gallon propane tanks to use as pressurized storage with a EKO 60. My question is - is there any advantage to how I install the 4 tanks? Standing each tank on end or stacking two together? I only have one zone (forced air furnace with lines already installed from a OWB). This is new construction so I have the opportunity to set it up right the first time. With a pressurized system, is it possible to get much stratification and how do I take advantage of it? Also, I'm thinking about using two 80 gallon hot-water heaters for expansion tanks, so where is the proper place to locate them? Can't wait for spring so I can start building this project instead of thinking and figuring!!

Multiable Propane Storage Tank Hook-Up

- Thread starter sdrobertson

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.