Hi everyone out there heating with wood, in my opinion the only way to go. My question- my new shop is about to be hooked up with a tarm solo40 wood gasification boiler. I understand that to get the most efficient heat I will need to purchase a 700 to 1000 gal water storage tank. My problem is space. The stock tanks from STSS CO INC sold only by Tarm are massive and require a good amount of my floor sq. footage. There custom tanks are expensive. Is there another manf. out there besides them that produces an insulated storage tank in more of a vertical position thus reducing the sq. ft. consumed? Thanks sweetheat

my 1st post question

- Thread starter sweetheat

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Nofossil

Moderator Emeritus

Some folks are using used 250 and 500 gallon propane tanks. I expect you could install one or more on end, though I don't know the dimensions. You'd have to insulate them yourself, but some framing and fiberglass would likely do the trick.

Eric Johnson

Mod Emeritus

Welcome to the Boiler Room, sweetheat. There are about a million different options for hot water storage--and more every day judging from the ideas being floated and implemented on this site. Going with a purpose-built tank and heat exchanger like the STSS is a great way to go, but probably way more expensive than some of the DIY alternatives.

Take some time to look around at some old threads and feel free to jump into discussions with questions or start some new threads. I'm sure you'll get plenty of help.

Take some time to look around at some old threads and feel free to jump into discussions with questions or start some new threads. I'm sure you'll get plenty of help.

I was wondering about these spray urethane foams that are getting very popular out here in the midwest. For example, Icenyne, is an expanding spray in foam insulation that is usually used in new construction or in retrofits of attics, etc. It completely seals off air gaps, leakages, etc. They typically advertise R7 per inch at a cost of ~$1/inch/sq ft. What if we were to hoist a small propane tank from its hooks and then spray a 4 to 6 inch layer of foam around it then bury it down below the frost line? What do you guys think? I seem to have the same problem as sweathart. I do not want to give up anymore floor space in my untility room. In addition, I o not want to add warm moisture to the inside of an already extremely tight house (i.e. mold).

I had come upon a photo within the last week on this site where someone was prefabbing walls and filling them with this stuff to put around a tank. I think there was a comment about how hard the foam ended up being. I'm not sure how tolerant it would be to ground water though. But using it in an above ground structure could be a viable option.

Good point. There are different types though. Some are closed cell and some are open. The closed cell is supposed to be impermeable to water just like the pink extruded polystyrene. But I suppose you could put a vapor barrier around it too. I just do not want a large tank in the yard.

jebatty

Minister of Fire

sweetheat said:. . . massive and require a good amount of my floor sq. footage. There custom tanks are expensive

I had/have the same problem, and I am "solving" it with a used LP tank, mounted horizontal, insulated, with a deck built over the top. I lost the floor space, but recovered space above for storage. With a little reorganization in my shop, it really worked out OK. Also, with the tank inside, all heat escaped from the tank goes into the heated space, resulting in a very efficient system. I also have not insulated the whole tank, but leave some exposed, and it acts as a radiator to heat the space without more. BTW, I also have the Tarm Solo Plus 40.

Seyiwmz

Member

Sweet-Heat,,,,,, I wouldn't "sweat it" if you can't get a tank hooked up. I'm working on my 4th year with a gasifier, and I finally put in a 500 gallon propane tank. I burn 24/ 7, so I haven't even had any benefit from putting it in. When temps rise outside I'll expect to use more by starting and stopping the fires. Till then, it just sits waiting patiently. My house is a big enough load for now. If you check out the link in my signature you'll find a video showing the size box it takes to cover and insulate a 500 gallon propane tank. Good Luck Seyiwmz

will the coils necessary for heat transfer fit inside the retro propane tanks? I assume these are unpressureized tanks. My understanding of the burn, and deposit of heat created to water makes the gasifier unit last a few more years. The tempering of heat transfered to water storage allows for more efficient use of the gasifier and slower burnout. I was told the transfer of high heat to the radiant slab will cause a quicker burnout. My goal is to do less work, use less wood and extract more BTU'S. Thanks to all who have posted to my questions. sweetheat in Maine

Eric Johnson

Mod Emeritus

Propane tanks are usually pressurized storage. That's why you need all that steel and engineering. For nopressurized storage, you can get by with much less in the way of tank integrity. And pressurized storage doesn't require a heat exchanger. You do need a pretty big expansion tank, though. Life's full of tradeoffs.

So pressurised tank vs non with heat exchangers. what about domistic hot water? wont you need an exchanger for that? What kind of pressure are we talking here? Will the pex tube in the slab be affected by the pressure? The tarm recommends there STSS CO INC. is there another manf out there making something simalar? that is compatable with the tarm 40? know of any DIY plans for water storage tanks. how long will EPDM glue seal last? My Dads shop roof a 3 pitch, with EPDM, 15 years direct weather contact. what else will contain water, retain heat, and not leak?

Eric Johnson

Mod Emeritus

Yes, you need a separate heat exchanger for domestic hot water. Many of use sidearm hx units, which you can build yourself for less than $100 and operate on gravity. They work well.

The pressure in most hydronic heating systems is around 15--30 psi max. The DHW is higher, of course.

There's really no such thing as "compatibility" with hot water storage tanks. Hot water is hot water and there are an infinite number of ways to store it and retrieve the heat, independent of the boiler producing it. Check around here and you'll find at least a dozen different DIY tank designs--probably a lot more.

As you point out, if EPDM can take the conditions it sees on a roof, it can take the conditions seen in a typical tank for a good long time.

The pressure in most hydronic heating systems is around 15--30 psi max. The DHW is higher, of course.

There's really no such thing as "compatibility" with hot water storage tanks. Hot water is hot water and there are an infinite number of ways to store it and retrieve the heat, independent of the boiler producing it. Check around here and you'll find at least a dozen different DIY tank designs--probably a lot more.

As you point out, if EPDM can take the conditions it sees on a roof, it can take the conditions seen in a typical tank for a good long time.

heaterman

Minister of Fire

What if we were to hoist a small propane tank from its hooks and then spray a 4 to 6 inch layer of foam around it then bury it down below the frost line?

Icynene will not work in contact with the ground nor will it support that kind of weight. You'd have to go with a urethane based product that hardens up good and stiff.

Icynene will not work in contact with the ground nor will it support that kind of weight. You'd have to go with a urethane based product that hardens up good and stiff.

Eric Johnson

Mod Emeritus

Welcome to the Boiler Room, JackM.

People use old propane tanks for pressurized hot water storage.

People use old propane tanks for pressurized hot water storage.

thanks for the advice eric. Jack m the lp tank is for pressureized hot water storage. eric can you briefly explain a heat exchanger with sidearm hx unit for domistic hot water. Would this be a separate tank? Also DHW? I assume direct hot water? for the house heat in the slab? what about all the new wood gasification boilers on the market are they dumping all that heat into the slab? I see nothing about water storage at the econoburn site or the EKO site! sweetheat

Eric Johnson

Mod Emeritus

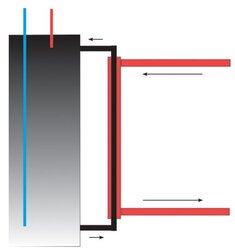

A sidearm heat exchanger attaches to a conventional water heater (or other relatively small tank) and heats the water in the tank through convection when you pump water from the boiler through the shell. Here's a diagram of how one works. You can build them with 1 1/4 or 1/1/2-inch copper pipe with a 3/4-inch tube and conventional reducer fittings. You can also buy them on Ebay or from OWB dealers. It's just another zone on your hydronic heating system.

You can run a gasifier without hot water storage (I have been), but hot water storage will help you get the most out of your system, in that you have to tend it less and you can fire it hard for optimum efficiency, stash the heat produced, and use it for heating your house and/or DHW. It's especially useful during warmer weather when your gasifier will produce more heat in a cycle than you can use. The reason gasifier mfg and dealer websites don't usually mention hot water storage (Tarm is a notable exception) is that a tank and heat exchangers adds considerable upfront cost to the system and since they don't sell tanks or heat exchangers, they don't want to put off potential customers with the added expense on top of what's already an expensive boiler compared to some of the alternatives.

Most people look at the price of the commercial tanks and hx and figure they can do better with a DIY setup. As such, we have many different approaches routinely discussed on this site, including the aforementioned propane tanks.

You can run a gasifier without hot water storage (I have been), but hot water storage will help you get the most out of your system, in that you have to tend it less and you can fire it hard for optimum efficiency, stash the heat produced, and use it for heating your house and/or DHW. It's especially useful during warmer weather when your gasifier will produce more heat in a cycle than you can use. The reason gasifier mfg and dealer websites don't usually mention hot water storage (Tarm is a notable exception) is that a tank and heat exchangers adds considerable upfront cost to the system and since they don't sell tanks or heat exchangers, they don't want to put off potential customers with the added expense on top of what's already an expensive boiler compared to some of the alternatives.

Most people look at the price of the commercial tanks and hx and figure they can do better with a DIY setup. As such, we have many different approaches routinely discussed on this site, including the aforementioned propane tanks.

Attachments

Chris S.

New Member

jebatty said:sweetheat said:. . . massive and require a good amount of my floor sq. footage. There custom tanks are expensive

I had/have the same problem, and I am "solving" it with a used LP tank, mounted horizontal, insulated, with a deck built over the top. I lost the floor space, but recovered space above for storage. With a little reorganization in my shop, it really worked out OK. Also, with the tank inside, all heat escaped from the tank goes into the heated space, resulting in a very efficient system. I also have not insulated the whole tank, but leave some exposed, and it acts as a radiator to heat the space without more. BTW, I also have the Tarm Solo Plus 40.

Hello All- first time poster here, been lurking for awhile trying to learn enough to set up my own system. I ran into the same constraints when it came to a heat storage tank- namely cost and floor space. The round shape of a Tarm/STSS tanks just didn't work in my building- and they were pretty pricey. I researched all kind of options- various tank materials, burying underground, etc. I had a hard time finding a tank that was structurally sound enough to be burried. Also most of the "plastic" type tanks didn't like water temps in the 180-200 F range. I ended up buying a used dairy bulk cooling tank, $1,000 from a local farmer. 1000 gallons, stainless steel inner liner with a foam insulation layer around freon pipes (which I won't use- has been drained) and then a SS outer layer. The big plus for me was that it is 5 feet wide by 10 feet long with an oval cross section. This shape just worked much better for me. I had to cut a hole in the top to drop 3 heat exchangers in- and will have to drill some holes to get the pipes in/out. I'm struggling with the insulation issue now. My original thought was to spray Icynene around the tank. I'm reconsidering b/c if there are any maintenance/alteration needs in the future the Icynene is going to make it tough to remove the tank or get at it for repairs. I might just do some fiberglass draped over/around the tank... or maybe some foil faced foam board.

Sweetheat, this forum is an excellent source of inspiration- keep searching b/c there are numerous posts on DIY storage tanks with great ideas and valuable insights.

Nofossil

Moderator Emeritus

I'm going to have to add more content to my section on storage tanks - same questions / issues come up often.

Some random thoughts:

I'm a fan of an insulation system that can be dis-assembled because things will go wrong.

12" of insulation is not excessive given that the temperature difference between that water and the environment is so high.

Getting a good cover seal on an non-pressurized tank is critical to eliminate evaporative loss and the resultant wet insulation.

I think that a radiation trap - a 3/4" airspace with foil on both sides - is a good thing, especially near the tank where temperatures are high. The cavity must be absolutely sealed to prevent convective losses.

Some random thoughts:

I'm a fan of an insulation system that can be dis-assembled because things will go wrong.

12" of insulation is not excessive given that the temperature difference between that water and the environment is so high.

Getting a good cover seal on an non-pressurized tank is critical to eliminate evaporative loss and the resultant wet insulation.

I think that a radiation trap - a 3/4" airspace with foil on both sides - is a good thing, especially near the tank where temperatures are high. The cavity must be absolutely sealed to prevent convective losses.

I'm back with some more questions. I've been looking at some threads about DIY water storage tanks. EPDM or poly vs retro propane steel and insulation? Pressurised or non? Pex or copper coils? Self built or bought? What is the life of EPDM? Will it out last steel under pressure? I've built many boxes in my life span. I'm sure I can build a box strong enough to with stand 800 gal of water pressure. Will EPDM glued lap joints last? Thanks to all for your answers. I'm getting closer to the installation of a tarm solo 40. The more I learn the more I think I should wait for more info to trickle into my brain. It's got to be there before next winter! sweetheat

Are there any other un- pressureized tank manf out there besides STSS CO INC? Do they have any compitetion?

- Status

- Not open for further replies.

Similar threads

- Replies

- 6

- Views

- 1K

- Replies

- 25

- Views

- 6K

- Replies

- 34

- Views

- 6K

- Replies

- 10

- Views

- 1K