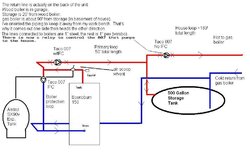

Someone had suggested that I post my layout for reference purposes. It's not exact, but it's as close as I can do with MS Paint. It's kind of a "Simplest Pressurized System" and Piker's personal layout put together. The closely spaced tees by the storage tank work well. I have a small diameter transfer run to the house (1" pex). There is only a Taco 007 on that run also. The boiler's main circ (also a 007) circulates water faster than the transfer circ so it ends up charging the storage with whatever the transfer circ can't take. Not bad, but not a great scenario either.

My Eburn 150 setup w/500 gallon storage

- Thread starter Huskurdu

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

Similar threads

- Locked

I'm going to give them a break for a while.

I'm going to give them a break for a while.