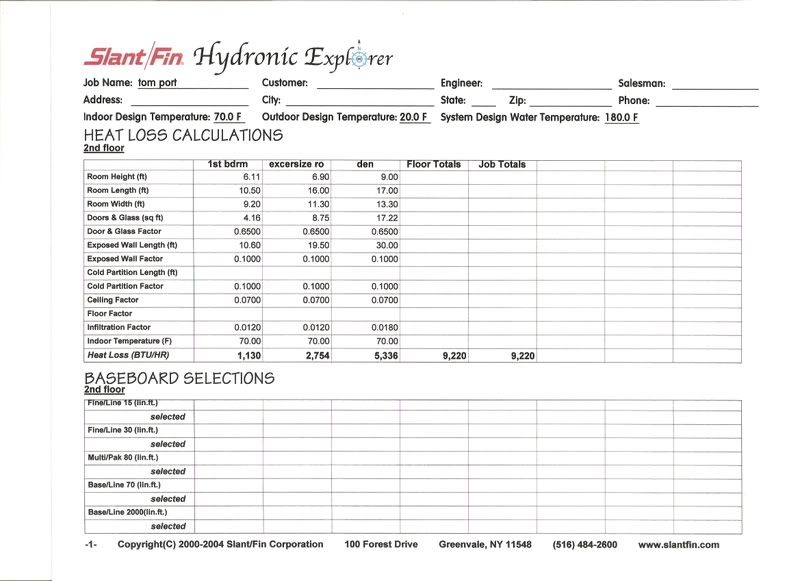

i dont know if seems right or not??

i hope you can read it. im going to be installing the haydon 750 series baseboard heaters upstairs into 1 big loop on the outside walls of these rooms and the haydens are rated at

180F @ 4 GPM = 610BTU/hr

180F @ 1GPM = 580BTU/hr

this is rated on PER FOOT

if this seems right that means i need only 2FT of baseboard heater for the 1ST bdrm??? and then i need to run 8 FT of just the "frame " of the baseboard the rest?

i hope you can read it. im going to be installing the haydon 750 series baseboard heaters upstairs into 1 big loop on the outside walls of these rooms and the haydens are rated at

180F @ 4 GPM = 610BTU/hr

180F @ 1GPM = 580BTU/hr

this is rated on PER FOOT

if this seems right that means i need only 2FT of baseboard heater for the 1ST bdrm??? and then i need to run 8 FT of just the "frame " of the baseboard the rest?

ill change it and see what the dif. is

ill change it and see what the dif. is