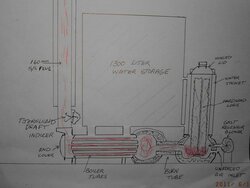

I am currently building a wood fired boiler based on the design by Richard C Hill for a Stick-Wood Fired furnace.

I am about a month away from completion. My efforts can be viewed on the following link:

https://sites.google.com/site/mywoodfiredhydronicboiler/my-construction-of-a-wood-fired-boiler

I will be making frequent additions to the web site.

Regards

I am about a month away from completion. My efforts can be viewed on the following link:

https://sites.google.com/site/mywoodfiredhydronicboiler/my-construction-of-a-wood-fired-boiler

I will be making frequent additions to the web site.

Regards

, maybe air. Especially if the load was low and the storage side heat exchanger had a high surface area. Air! Eureka. Runs naked in the woods :ahhh: .

, maybe air. Especially if the load was low and the storage side heat exchanger had a high surface area. Air! Eureka. Runs naked in the woods :ahhh: .